Complex aqueous solution for preparing self-repairing anti-fog frost prevention coating and application thereof

A compound and self-repairing technology, applied in the field of chemical coatings, can solve the problems of restricting anti-fog and anti-frost coatings, anti-fog film movement restrictions, and self-repairing performance reduction, achieving excellent stability, excellent repairing ability, and maintaining transparency sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1 A composite aqueous solution for preparing a self-repairing anti-fog and anti-frost coating, the amount of each raw material calculated by mass fraction is as follows:

[0018] 1) poly-2-acrylamide-2-methylpropanesulfonic acid (water absorbing agent), 2%; 2) polyvinylimidazole (stabilizer), 2%, the mass fraction of water contained is 96%.

[0019] After mixing poly-2-acrylamide-2-methylpropanesulfonic acid and polyvinylimidazole in water, a uniform and transparent composite aqueous solution with a total mass fraction of 4% is obtained.

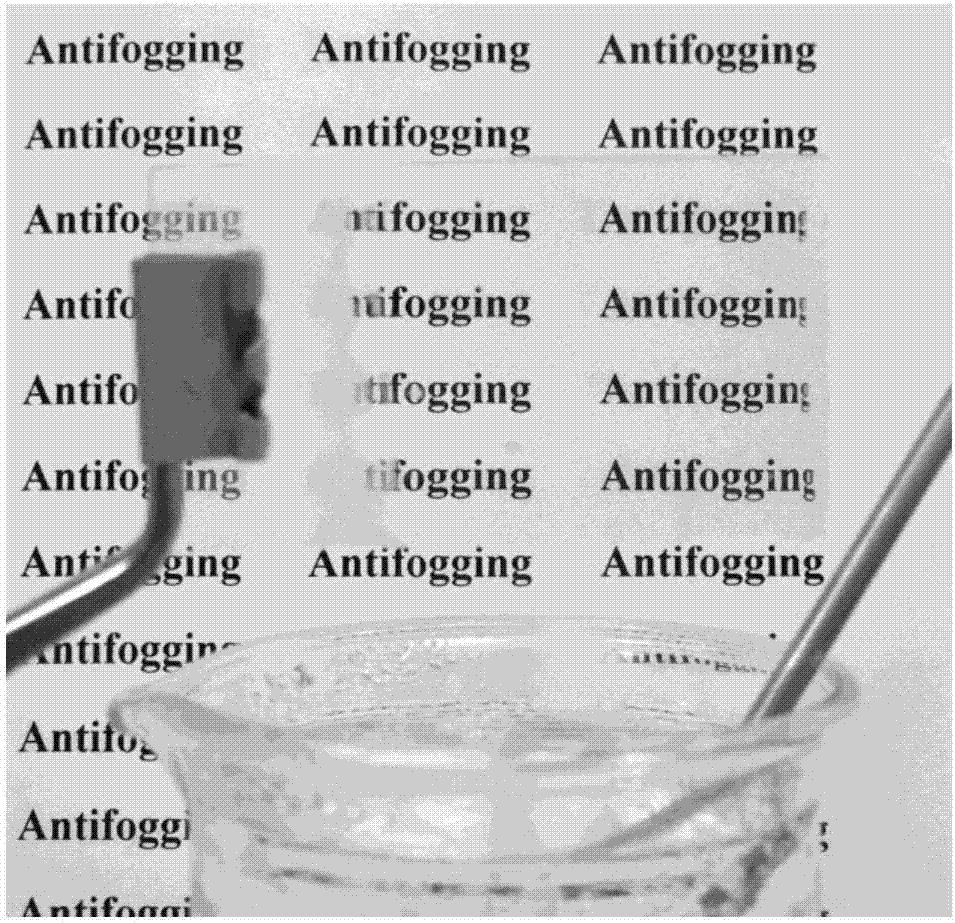

[0020] The spraying method can be used in 10*10cm 2 A 10 μm thick highly transparent composite coating is constructed on the glass surface. The inner diameter of the nozzle of the spray gun used was 500 μm, and 0.2 ml of the composite aqueous solution could be sprayed per second. After the coating is dried naturally, place the coated material in a refrigerator at minus 20°C for 2 hours, and then place it in an environment...

Embodiment 2

[0021] Embodiment 2 A composite aqueous solution for preparing a self-repairing anti-fog and anti-frost coating, the amount of each raw material calculated by mass fraction is as follows:

[0022] 1) hyaluronic acid (water-absorbing agent), 6%; 2) branched polyethyleneimine (stabilizer), 1%, and the mass fraction of water contained is 93%.

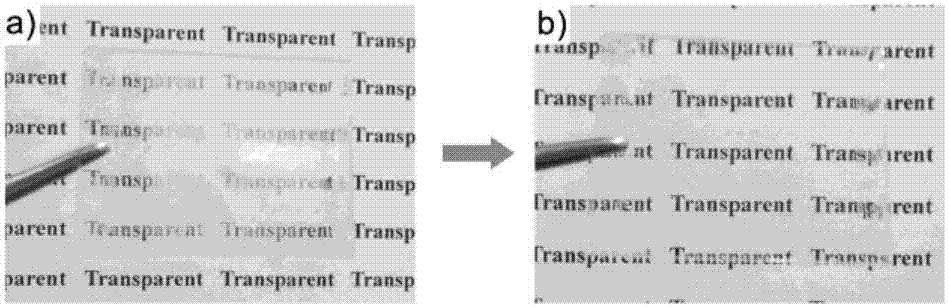

[0023] When hyaluronic acid and branched polyvinylimine are mixed in water, the viscosity of the solution increases, and finally a uniform and transparent composite solution is formed. Concentrate the complex aqueous solution at 65°C to finally obtain a complex solution with a total mass fraction of 12%. A highly transparent composite coating with a thickness of 20 μm was constructed on the surface of the left lens of the myopia lens by pulling and forming a film. The process of pulling and forming a film is realized by means of a pulling film coating machine. First, spectacle lenses were vertically dipped into the composite solution at ...

Embodiment 3

[0024] Embodiment 3 A composite aqueous solution for preparing a self-repairing anti-fog and anti-frost coating, the amount of each raw material calculated by mass fraction is as follows:

[0025] 1) sodium alginate (water absorbent), 12%; 2) polydiallyldimethylamine hydrochloride (stabilizer), 2%, 3) silicon dioxide (toughener), 1%, all The mass fraction of water is 85%.

[0026] When sodium alginate, polydiallyldimethylamine hydrochloride and silicon dioxide are mixed in water, the viscosity of the solution increases, and finally a uniform and transparent composite solution is formed. 15*15cm by scraping 2 The PET and glass surfaces are constructed with a 20 μm thick highly transparent polymer coating. It can be found that the anti-fog and anti-frost coating has good flexibility, and the PET substrate deposited with the composite coating was repeatedly bent 2000 times, and the coating was not broken or detached from the substrate. The material with the composite coating w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com