Oxide semiconductor thin film and thin film transistor prepared from same

A technology of oxide semiconductors and oxides, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as limited stability improvement, increased complexity, and application field limitations, and achieve excellent light stability, The effect of simple preparation process and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

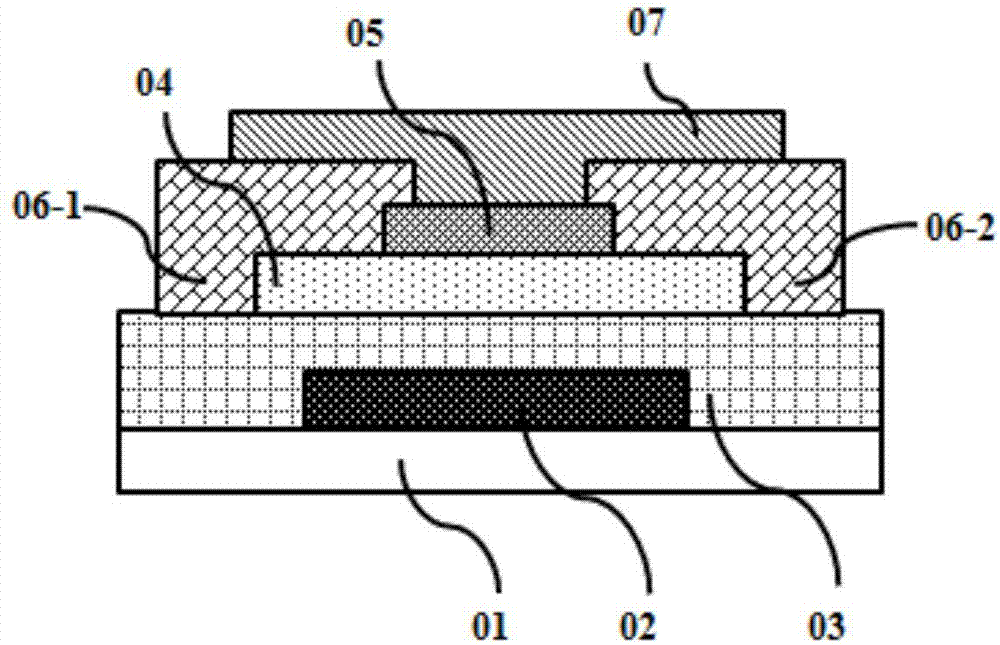

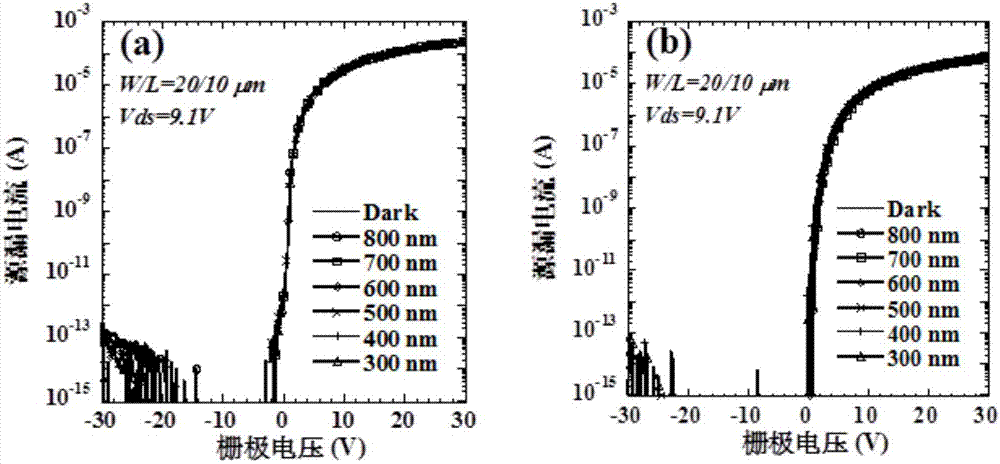

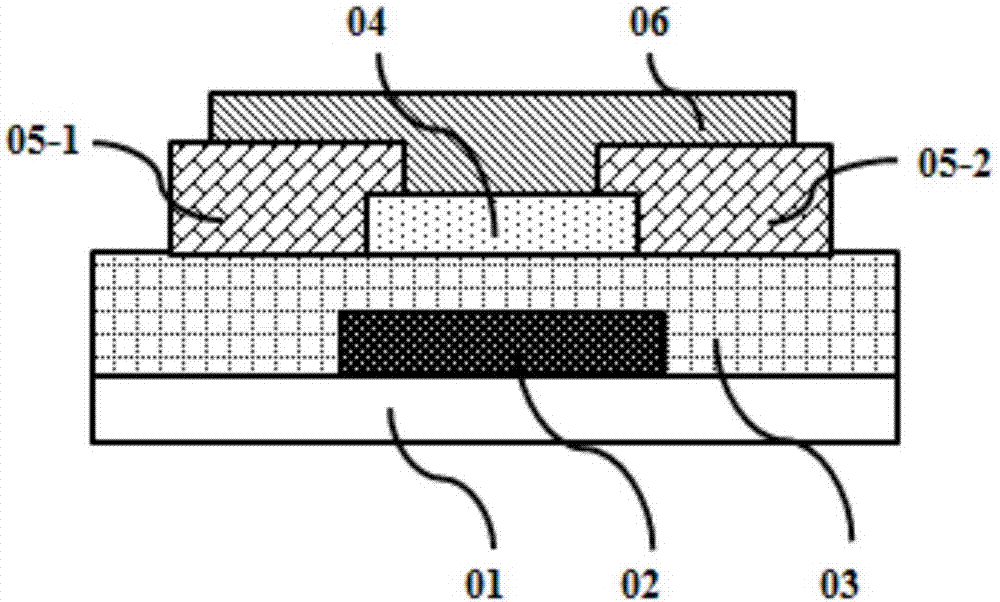

[0029] An oxide semiconductor film in this embodiment, the oxide semiconductor film is: a small amount of praseodymium oxide is doped into the indium zinc oxide semiconductor film by ceramic target magnetron sputtering as a light stabilizer to form a praseodymium oxide-doped oxide film. Indium zinc (Pr:IZO) semiconductor thin film material, wherein, Pr:In:Zn=0.2:5:1mol. The thickness of Pr:IZO semiconductor film is 20nm, and the carrier concentration is less than 5×10 19 cm -3 .

Embodiment 2

[0031] An oxide semiconductor film in this embodiment, the oxide semiconductor film is: a small amount of terbium oxide is doped into the indium gallium zinc oxide semiconductor film by ceramic target magnetron sputtering as a light stabilizer to form a terbium oxide doped Indium Gallium Zinc Oxide (Tb:IGZO) semiconductor thin film material, wherein Tb:In:Ga:Zn=0.1:1:1:0.5mol. The thickness of Tb:IGZO semiconductor film is 40nm, and the carrier concentration is less than 5×10 19 cm -3 .

Embodiment 3

[0033] An oxide semiconductor film in this embodiment, the oxide semiconductor film is: a small amount of thulium oxide is doped into the indium tin zinc oxide semiconductor film by atomic layer deposition as a light stabilizer to form thulium oxide doped indium tin oxide Zinc (Dy:ITZO) semiconductor thin film material, wherein Dy:In:Sn:Zn=0.1:1:1:1mol. Dy:ITZO semiconductor thin film has a thickness of 30nm and a carrier concentration of less than 5×10 19 cm -3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Carrier concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com