Glutathione/ultrasound dual stimulation response nano polymer vesicles and preparation method and application thereof

A dual-stimuli-response, nano-polymer technology, applied in the field of biomedicine, can solve problems such as low dosage and human side effects, and achieve the effects of reducing side effects, good comprehensiveness, and clear and concise preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

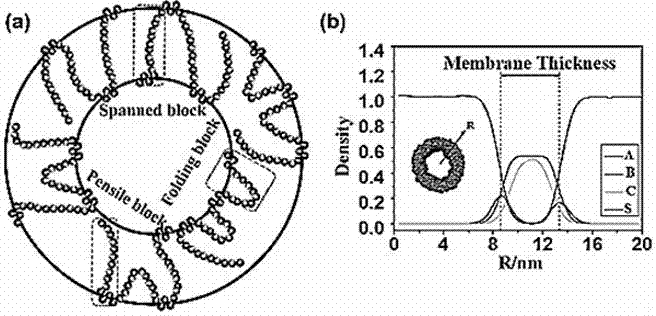

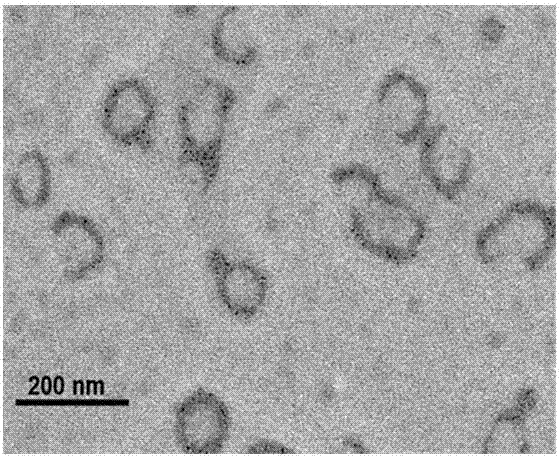

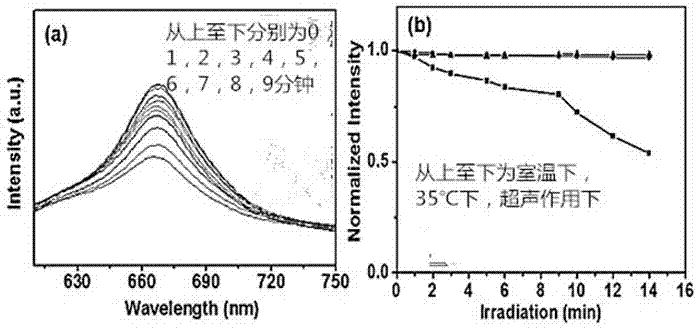

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Add 1g of calcium chloride, 22.5ml of solvent N-methylpyrrolidone and 2.5ml of pyridine into the reaction bulb, slowly heat to 70°C, and stir to dissolve it completely. Subsequently, 2.68 g of sodium isophthalic acid-5-sulfonate and 5.24 ml of triphenyl phosphite were added to the solution, and after they were completely dissolved, 1.16 g of hexamethylenediamine was added. Then turn off the temperature controller, and after the solution is cooled, pump it out three times, and replace the air in the system with nitrogen. Under the inert atmosphere of the system, heating was started to raise the temperature to 95° C., and the reaction was carried out for 3 hours. A hydrophilic polyamide segment is obtained.

[0031] 2) Add 1g of calcium chloride, 22.5ml of N-methylpyrrolidone and 2.5ml of pyridine into another reaction bulb, slowly heat to 70°C, and stir to dissolve them completely. Subsequently, 2.10 g of 3,3'-dithiodipropionic acid and 5.24 mL of triphenyl phosphit...

Embodiment 2

[0035] 1) Add 0.5g of magnesium chloride and 0.52g of lithium chloride, 13.2ml of solvent N-methylpyrrolidone and 3.8ml of pyridine into the reaction bulb, slowly heat to 40°C, and stir to dissolve them completely. Subsequently, 2.68 g of sodium isophthalic acid-5-sulfonate and 5.24 ml of triphenyl phosphite were added to the solution, and after they were completely dissolved, 0.6 g of ethylenediamine was added. Then turn off the temperature controller, and after the solution is cooled, pump it out three times, and replace the air in the system with nitrogen. Under the inert atmosphere of the system, heating was started to raise the temperature to 100° C., and the reaction was carried out for 20 hours. A hydrophilic polyamide segment is obtained.

[0036] 2) Add 0.2g of calcium chloride and 0.2g of lithium chloride, 6.22ml of N-methylpyrrolidone and 1.78ml of pyridine into another reaction bulb, slowly heat to 40°C, and stir to dissolve them completely. Subsequently, 1.225 g...

Embodiment 3

[0040] 1) Add 0.5g of calcium chloride and 0.5g of lithium chloride, 8.89ml of solvent N-methylpyrrolidone and 1.11ml of pyridine into the reaction bulb, slowly heat to 70°C, and stir to dissolve them completely. Subsequently, 2.68 g of sodium terephthalate-5-sulfonate and 5.24 ml of triphenyl phosphite were added to the solution, and after they were completely dissolved, 0.88 g of butanediamine was added. Then turn off the temperature controller, and after the solution is cooled, pump it out three times, and replace the air in the system with nitrogen. Under the inert atmosphere of the system, heating was started to raise the temperature to 105° C., and the reaction was carried out for 12 hours. A hydrophilic polyamide segment is obtained.

[0041] 2) Add 0.5g of calcium chloride and 0.1g of lithium chloride, 5.56ml of N-methylpyrrolidone and 4.44ml of pyridine into another reaction bulb, slowly heat to 70°C, and stir to dissolve them completely. Subsequently, 0.9 g of thio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com