Low-temperature growing method for graphene

A graphene and low-temperature technology, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of high energy consumption, high temperature, and low output, and achieve excellent structural performance, simple equipment, and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1) Using crystalline sodium chloride (NaCl) as the substrate, a layer of Zn film with a thickness of 10nm was pre-deposited on it by magnetron sputtering;

[0021] 2) Put the above-mentioned NaCl substrate pre-deposited with Zn film in a tubular resistance furnace, heat it to 300°C, and feed H2-CH4-N2 as the reaction gas, the gas pressure is 55Pa, and the partial pressure of H2:CH4:N2 The ratio is 25:60:15, and the reaction takes 3.5 hours;

[0022] 3) After the reaction, turn off the power, stop feeding N2 and CH4, continue to feed H2 gas, and raise the gas pressure to 1000Pa, use H2 gas to cool, quickly cool the sample to room temperature, and obtain the desired product.

Embodiment 2

[0024] 1) Using crystalline sodium chloride (NaCl) as the substrate, a layer of Zn film with a thickness of 10nm was pre-deposited on it by magnetron sputtering;

[0025] 2) Put the above-mentioned NaCl substrate pre-deposited with Zn film in a tubular resistance furnace, heat it to 350°C, and feed H2-CH4-N2 as the reaction gas, the gas pressure is 50Pa, and the partial pressure of H2:CH4:N2 The ratio is 25:60:15, and the reaction takes 3.5 hours;

[0026] 3) After the reaction, turn off the power, stop feeding N2 and CH4, continue to feed H2 gas, and raise the gas pressure to 1000Pa, use H2 gas to cool, quickly cool the sample to room temperature, and obtain the desired product.

Embodiment 3

[0028] 1) Using crystalline sodium chloride (NaCl) as the substrate, a layer of Zn film with a thickness of 10nm was pre-deposited on it by magnetron sputtering;

[0029] 2) Put the above-mentioned NaCl substrate pre-deposited with Zn film in a tubular resistance furnace, heat it to 300°C, and feed H2-CH4-N2 as the reaction gas, the gas pressure is 60Pa, and the partial pressure of H2:CH4:N2 The ratio is 25:60:15, and the reaction takes 3.5 hours;

[0030] 3) After the reaction, turn off the power, stop feeding N2 and CH4, continue to feed H2 gas, and raise the gas pressure to 1000Pa, use H2 gas to cool, quickly cool the sample to room temperature, and obtain the desired product.

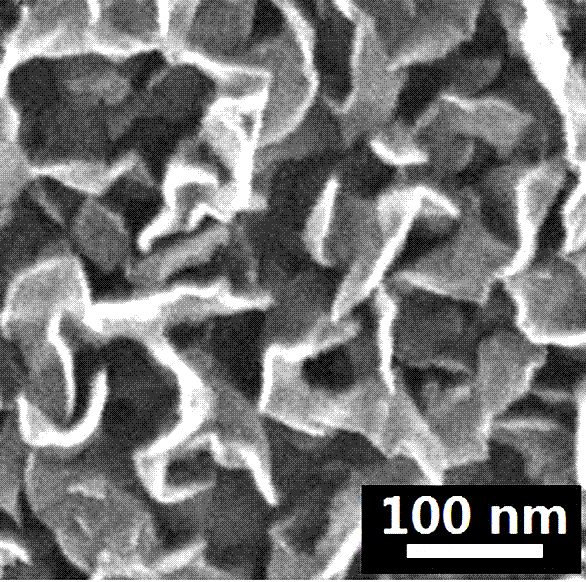

[0031] Adopt scanning electron microscope to carry out microscopic appearance observation to the final product graphene that each embodiment makes, as figure 1 It is a scanning electron microscope (SEM) picture of the low-temperature grown graphene material obtained in Example 1. The figure shows ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com