Alkali metal gallate glass and preparation method thereof

A gallate and alkali metal technology, applied in the field of alkali metal gallate glass and its preparation, can solve the problems of complex production process, poor chemical stability of fluoride glass and sulfide glass, etc., and achieve the effect of good light absorption characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) The molar composition of each component is: 65% Ga2O3, 23% La2O3, 12% Na2O;

[0033] 2) Weigh the total amount of 50 grams and mix it evenly in a mortar;

[0034] 3) Move the uniformly mixed powder in 2) to a platinum crucible, put it in an electric furnace and heat it to 1550℃, and keep it for 4 hours;

[0035] 4) Pour the melt into a stainless steel mold, cool it naturally, and then put it into a muffle furnace for annealing. The annealing process is controlled by a program, kept at 700 °C for 24 hours, and then cooled to room temperature;

[0036] 5) Cut, finely grind and polish the glass sample into a 20×20×2 mm sample.

[0037] 6) Using Meticon Model 2010 Prism Coupler waveguide analyzer to test its refractive index is 1.72.

Embodiment 2

[0039] The molar composition of each component is: 69% Ga 2 O 3 , 11% La 2 O 3 , 20% Na 2 O;

[0040] According to the preparation method of Example 1, the temperature in step 3) is controlled at 1600° C. and maintained for 2 hours; the annealing temperature in step 4) is 750° C. and maintained for 20 hours. The refractive index of the obtained infrared optical glass was 1.74.

Embodiment 3

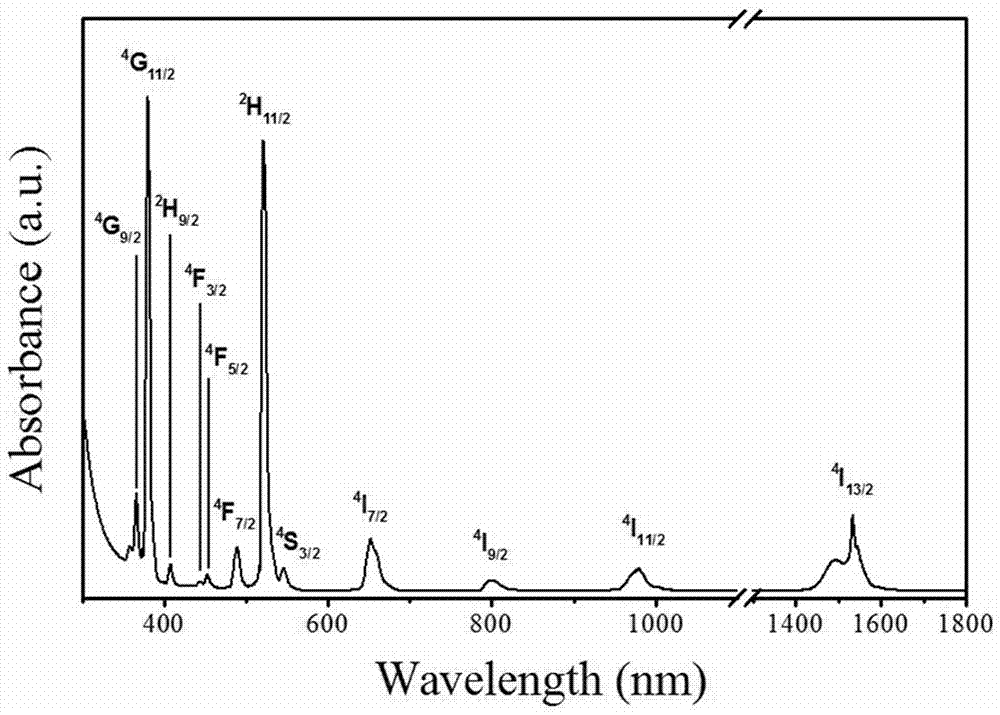

[0042] The molar composition of each component is: 64% Ga 2 O 3 , 23% La 2 O 3 , 12% Na 2 O, doped with 1% Er 2 O 3 . ;

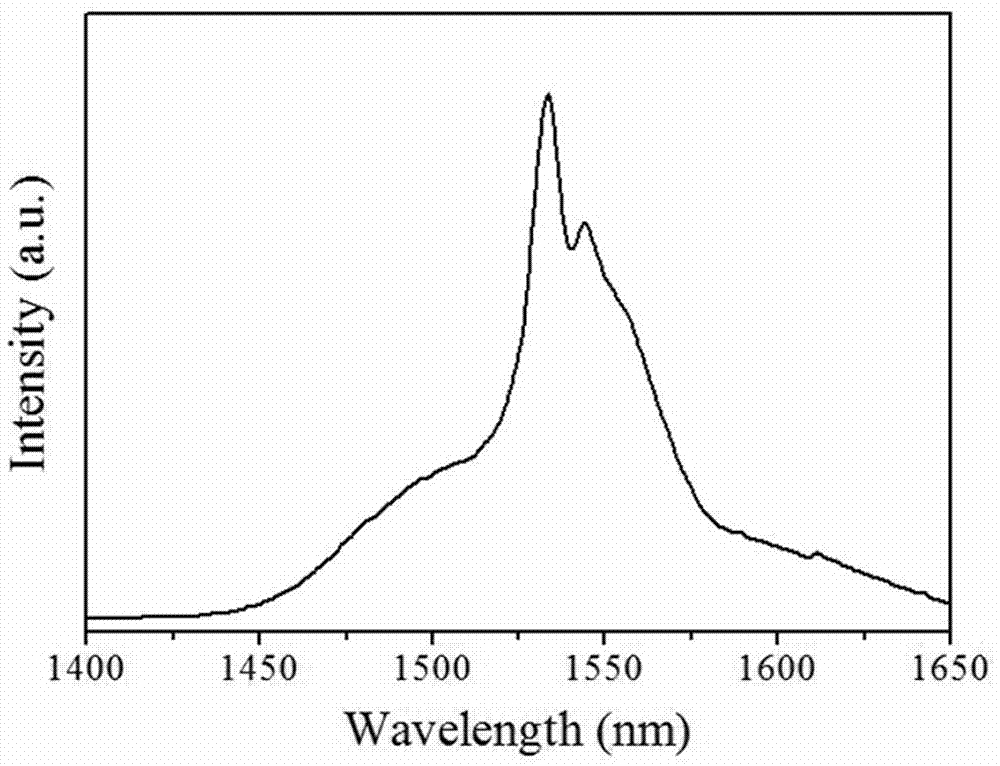

[0043] Press embodiment 1 preparation method, the refractive index of the infrared optical glass obtained is 1.73, adopt UV / VIS / NIR Lambda9 spectrophotometer to test absorption spectrum, as figure 1 shown. Under the condition of 980 nm laser pumping, the fluorescence spectrum at 1.5 μm is measured as shown in figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com