Alkali-activated slag cement retarder and preparation method thereof

A technology of alkali slag cement and retarder, applied in the field of building materials, can solve problems such as not being widely used, and achieve the effects of inhibiting the phenomenon of efflorescence, simple use and good retardation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

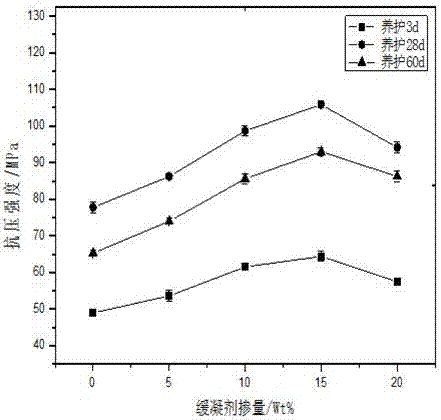

[0026] Take by weighing 45kg of industrial-grade boric acid, 25kg of brown sugar, and 30kg of superfine slag powder, and fully mix the raw materials of the above-mentioned quality in a mixer for 10 hours to ensure that they are fully mixed. The mixed material was ground in a ball mill for 5 hours, and its specific surface area was determined to be 480m 2 / kg. attached by figure 1 It can be seen that with the increase of retarder content, the compressive strength of alkali slag cement first increases and then decreases, and the optimum retarder content is 15.0%. The addition of retarder can increase the setting time of alkali slag cement, improve the fluidity of alkali slag cement slurry, and increase the compactness of samples, thereby improving the compressive strength.

Embodiment 2

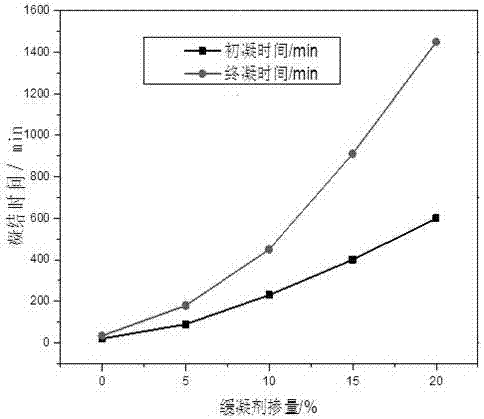

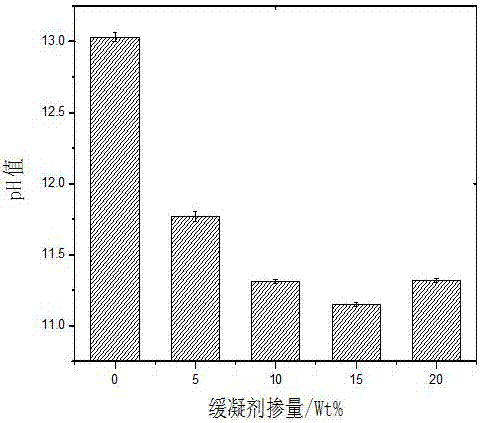

[0028] Weigh 40kg of industrial-grade boric acid, 20kg of sucrose, and 40kg of superfine slag powder, and fully mix the above-mentioned quality raw materials in a mixer for 10 hours to ensure that they are fully mixed. The mixed material was ground in a ball mill for 6 hours, and its specific surface area was determined to be 500m 2 / kg. attached by figure 2 It can be seen that with the increase of retarder, the initial setting time, final setting time and interval of alkali slag cement increase, and the setting time can be adjusted, which is beneficial to the construction and use of alkali slag cement. attached image 3 It shows that the increase of retarder content can improve the pH value of hardened slurry of alkali slag cement and inhibit the efflorescence of alkali slag cement after hardening.

Embodiment 3

[0030] Weigh 50kg of industrial-grade boric acid, 30kg of brown sugar, and 20kg of superfine slag powder, and fully mix the above-mentioned quality raw materials in a mixer for 10 hours to ensure that they are fully mixed. The mixed material was ground in a ball mill for 7 hours, and its specific surface area was determined to be 545m 2 / kg. attached by Figure 4 It can be seen that the concentration of carbonate ions is the characterization of the degree of efflorescence of alkali slag cement slurry. With the increase of retarder, the concentration of carbonate ions in the leaching solution of hardened slurry of alkali slag cement decreases first and then slightly increases. It fully shows that the retarder can inhibit the efflorescence of alkali slag cement. attached by Figure 5 It is not difficult to see that when the retarder is added at 15.0% mass fraction, the pore size of the hardened slurry of alkali slag cement is greatly reduced, from harmful pores gradually to h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com