Method for preparing ecological organic crude fertilizer through rapid degradation of livestock and poultry wastes

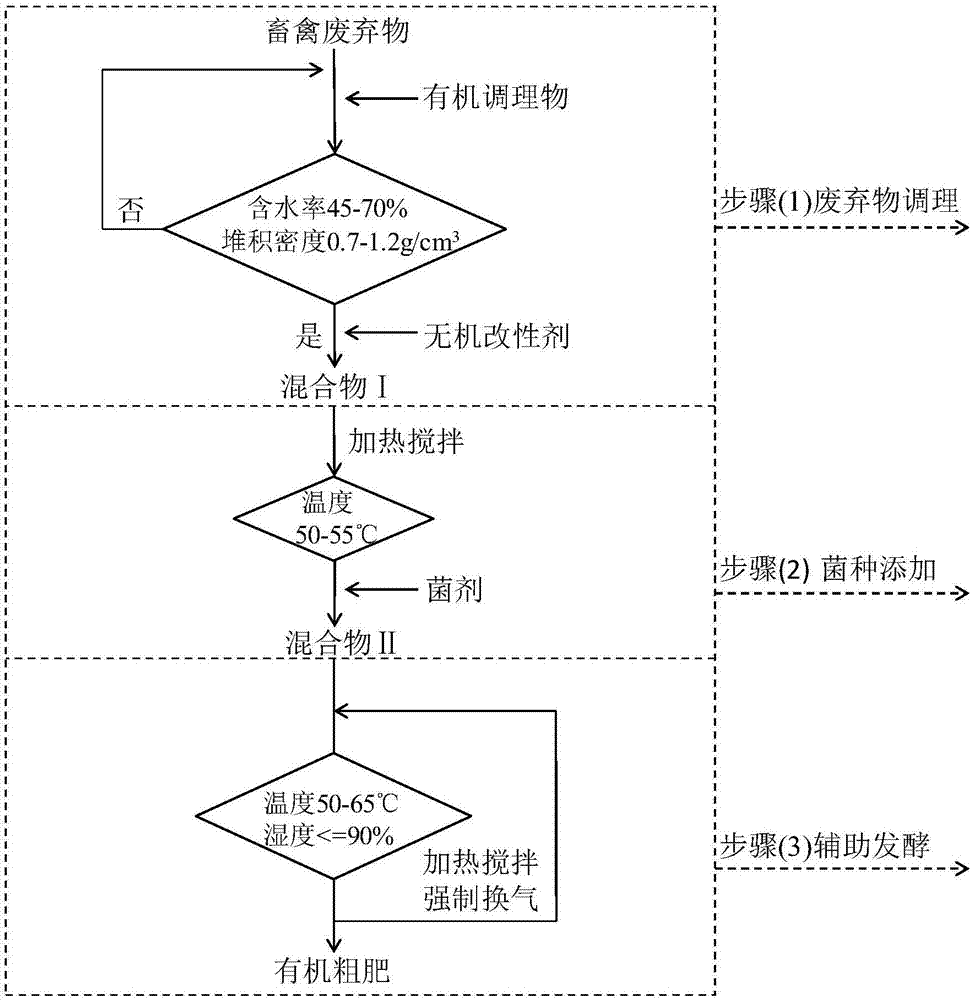

A rapid degradation technology for livestock and poultry waste, applied in the field of ecological organic coarse manure, can solve the problem of increased costs, numerous links in the process of resource utilization of livestock and poultry waste, and the lack of depth in the safe disposal of exogenous chemicals in livestock and poultry waste Fusion and other problems, to achieve volume reduction, improve dehydration characteristics, and facilitate rapid reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) conditioning waste: 64kg of fresh pig manure, 6kg of sawdust, and 2kg of rice husk are evenly mixed to obtain mixture A (i.e. livestock and poultry waste: organic conditioner=8:1), and the moisture content of gained mixture A is 68%. Density 0.72g / cm 3 , with a total mass of 72kg. CaO, FeSO 4 , FeCl 3 The inorganic modifier was mixed according to the mass ratio of 5:3:2, and 300g of the inorganic modifier was added to obtain the mixture I (the mass ratio of the inorganic modifier to the mixture A was 1 / 240).

[0028] (2) Adding strains: Heating the mixture I obtained in step (1), so that the internal temperature of the mixture I rises rapidly to 55° C., and the mixture I will lose part of the water when heated, and then add 100 g of enzyme bacteria to obtain mixture II (enzyme bacteria The mass ratio to mixture II is 1 / 700).

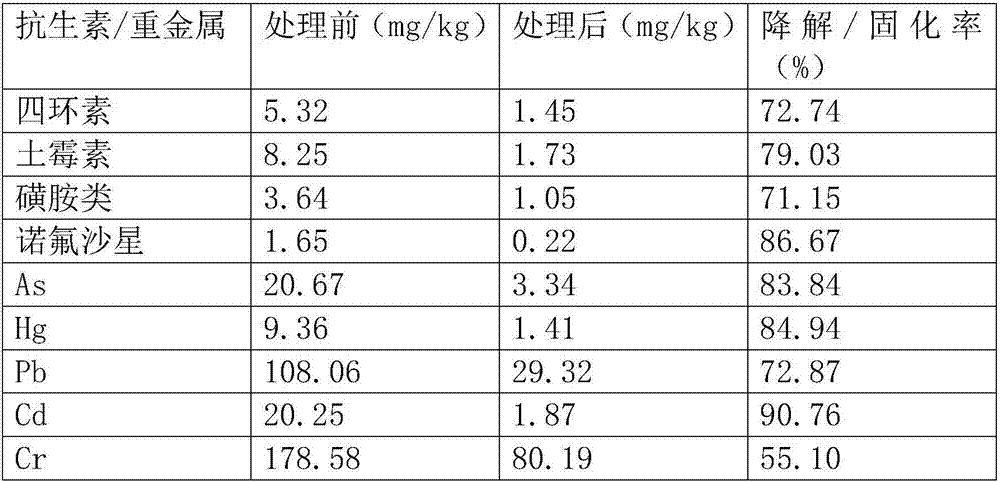

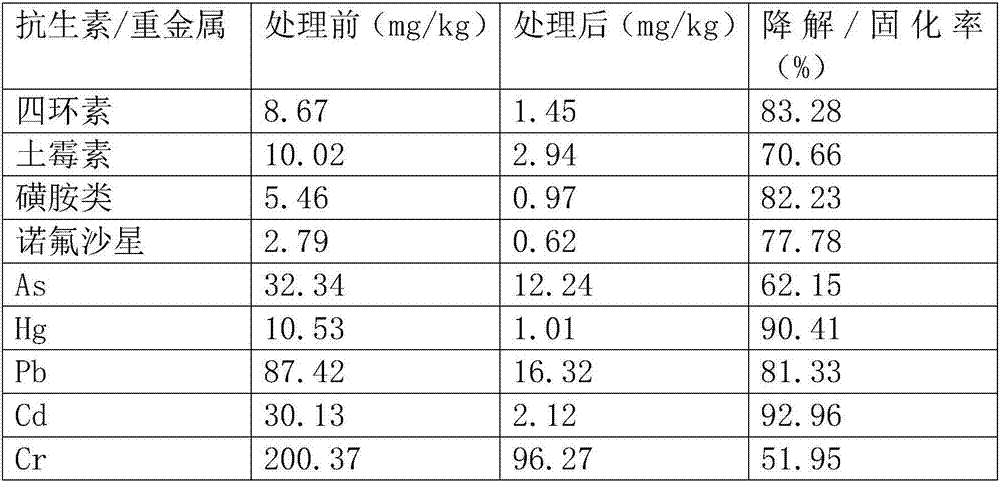

[0029] (3) Auxiliary fermentation: the internal temperature of the mixture II is controlled to be 60-65° C. and the humidity is 68%-90% b...

Embodiment 2

[0034] (1) Conditioning waste: Mix 5kg chicken manure and 30kg cabbage evenly to obtain mixture A (i.e. livestock and poultry waste: organic conditioner=1:6), the moisture content of the obtained mixture A is 70%, and the bulk density is 0.7g / cm 3 , with a total mass of 35kg, CaO (or Ca(OH) 2 ), FeCl 2 , CaO 2 The inorganic modifier was mixed according to the mass ratio of 4:3:3, and then 175g of the inorganic modifier was added to obtain the mixture I (that is, the mass ratio of the inorganic modifier to the mixture A was 1 / 200).

[0035] (2) Adding strains: heating the mixture I obtained in step (1), so that the internal temperature of the mixture I rises rapidly to 53° C., and the mixture I loses part of the water when heated, and then adds 40 g of a kind of enzyme bacteria to obtain the mixture II (enzyme The mass ratio of bacteria to mixture II was 1 / 850).

[0036] (3) Auxiliary fermentation: the internal temperature of the mixture II is controlled to be 53-57° C. and ...

Embodiment 3

[0041] (1) Conditioning waste: Mix 36.8kg of fresh cow dung and 10kg of straw evenly to obtain mixture A (i.e. livestock and poultry waste: organic conditioner=3.68:1), the moisture content of the obtained mixture A is 55%, and the bulk density is 0.7g / cm 3 , with a total mass of 46.8kg. Ca(OH) 2 , FeSO 4 , CaO 2 The inorganic modifier was mixed according to the mass ratio of 2:4:4, and then 156g of the inorganic conditioner was added to obtain the mixture I (the mass ratio of the inorganic modifier to the mixture A was 1 / 300).

[0042] (2) Adding strains: heating the mixture I obtained in step (1), so that the internal temperature of the mixture rises rapidly to 50° C., and the mixture I will lose part of its moisture when heated, and then add 31 g of Bacillus stearothermophilus to obtain the mixture II (the mass ratio of Bacillus licheniformis thermothelicheniformis to the mixture II is 1 / 1500).

[0043] (3) Auxiliary fermentation: the internal temperature of the mixtu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com