Green environmental protection flame retardant waterproof coating and preparation method thereof

A waterproof coating, green and environmental protection technology, applied in anti-corrosion coatings, fire-resistant coatings, polyurea/polyurethane coatings, etc., can solve problems affecting the application field of polyurethane waterproof coatings, material mechanical properties, damage to people's lives and property, etc. High practical value, cost reduction, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

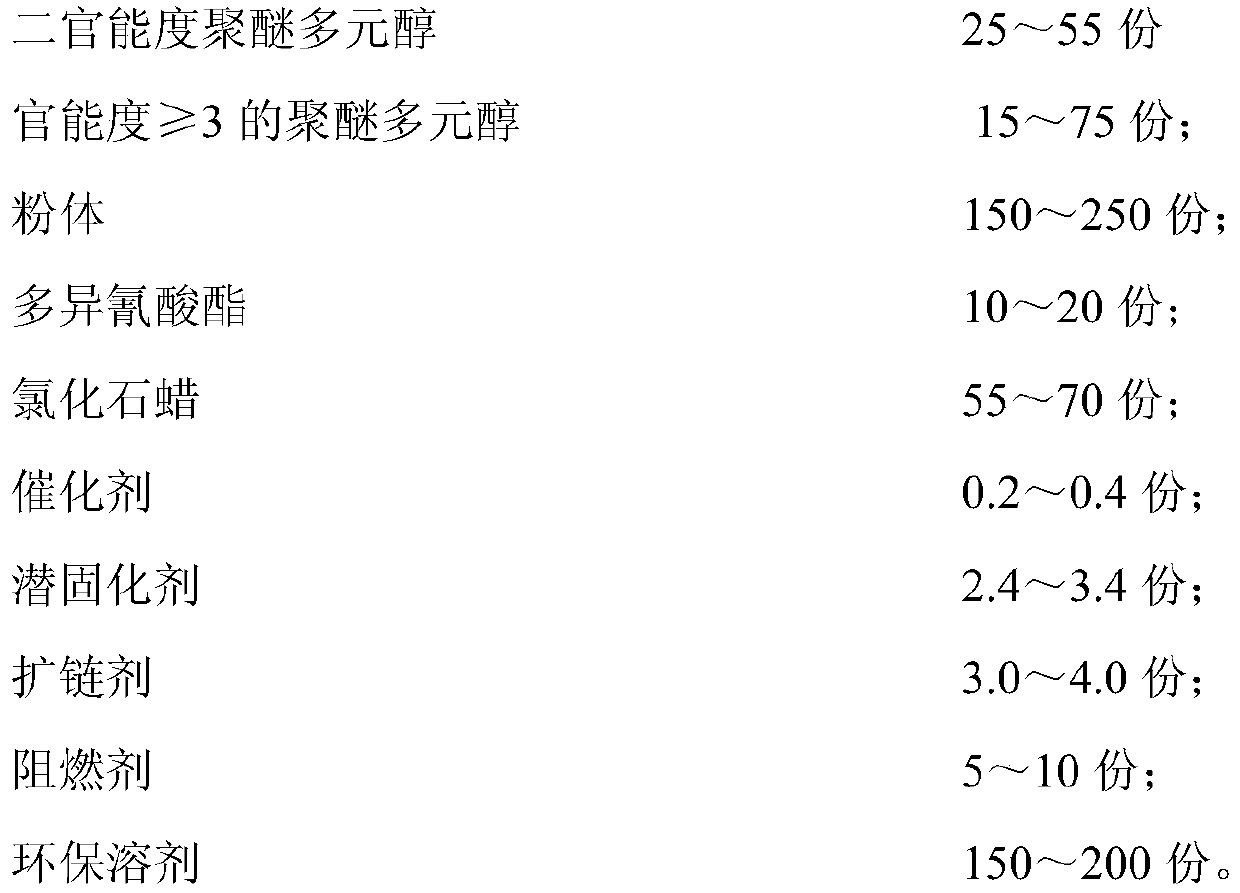

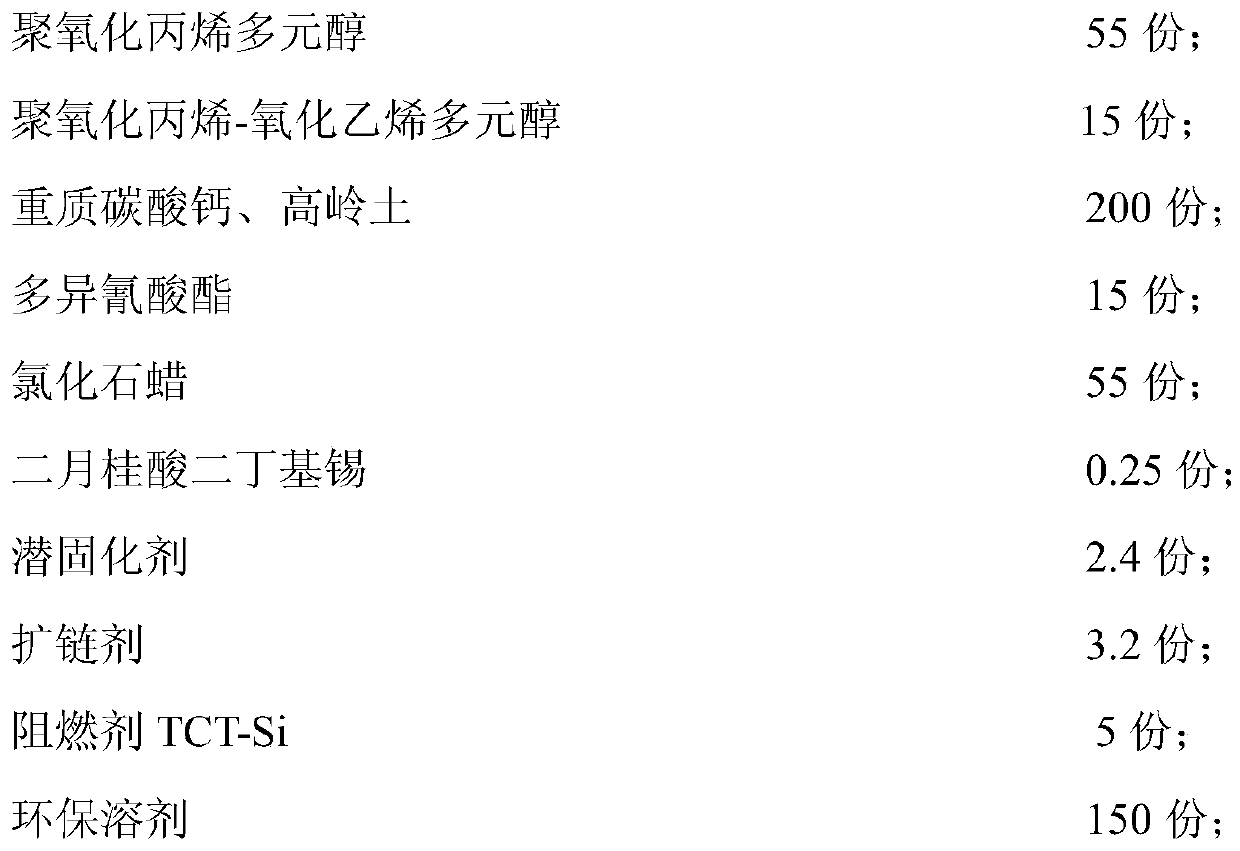

[0034] The green and environment-friendly flame-retardant waterproof coating is made of the following raw materials in parts by weight:

[0035]

[0036] The number average molecular weight of the polyoxypropylene polyol is 1500;

[0037] The number average molecular weight of the polyoxypropylene-oxyethylene polyol is 6000.

[0038] Its preparation method is as follows:

[0039] (1) Put the powder in a heated blast drying oven, bake at 120°C for 6 hours, and dehydrate;

[0040] (2) Add polyoxypropylene polyol, polyoxypropylene-oxyethylene polyol, and chain extender to the reactor, vacuumize to -0.09MPa, and dehydrate for 6 hours at a temperature of 110°C;

[0041] (3) Control the temperature of the polyether system to 50°C, add polyisocyanate, control the reaction temperature to 80°C, and the NCO of the final system is 1.0%;

[0042] (4) Add heavy calcium carbonate, kaolin, environmental solvent, chlorinated paraffin and latent curing agent to the reaction system in pro...

Embodiment 2

[0045] The green and environment-friendly flame-retardant waterproof coating is made of the following raw materials in parts by weight:

[0046]

[0047] The number average molecular weight of the polyoxypropylene polyol is 2000;

[0048] The number average molecular weight of the polyoxypropylene-oxyethylene polyol is 5500.

[0049] Its preparation method is as follows:

[0050] (1) Put the powder in a heated blast drying oven, bake at 130°C for 5 hours, and dehydrate;

[0051] (2) Add polyoxypropylene polyol, polyoxypropylene-oxyethylene polyol, and chain extender to the reactor, vacuumize to -0.09MPa, and dehydrate for 5 hours at a temperature of 100°C;

[0052] (3) Control the temperature of the polyether system to 70°C, add polyisocyanate, control the reaction temperature to 80°C, and the NCO of the final system is 0.9%;

[0053] (4) Add heavy calcium carbonate, talcum powder, environmental protection solvent, chlorinated paraffin and latent curing agent to the reac...

Embodiment 3

[0056] The green and environment-friendly flame-retardant waterproof coating is made of the following raw materials in parts by weight:

[0057]

[0058] The number average molecular weight of the polyoxypropylene polyol is 2200;

[0059] The number average molecular weight of the polyoxypropylene-oxyethylene polyol is 5000.

[0060] Its preparation method is as follows:

[0061] (1) Put the powder in a heated blast drying oven, bake at 125°C for 4.5 hours, and dehydrate;

[0062] (2) Add polyoxypropylene polyol, polyoxypropylene-oxyethylene polyol, and chain extender to the reactor, vacuumize to -0.09MPa, and dehydrate for 4.5 hours at a temperature of 95°C;

[0063] (3) Control the temperature of the polyether system at 50°C, add polyisocyanate, control the reaction temperature at 90°C, and the final NCO of the system is 1.2%;

[0064] (4) Add talcum powder, kaolin, environment-friendly solvent, chlorinated paraffin and latent curing agent into the reaction system in p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com