Double-component silicone rubber sealing agent for automobile lamp assembling sealing and preparation method thereof

A technology for assembly sealing and automotive lights, applied in the direction of adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problems of slow curing speed and low initial bonding strength, and achieve improved bonding Performance, good bonding performance and environmental resistance, the effect of preventing penetration and destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention also provides a method for preparing the above-mentioned two-component silicone rubber sealant for assembly and sealing of automobile lamps, comprising the following steps:

[0042] Component A is prepared as follows:

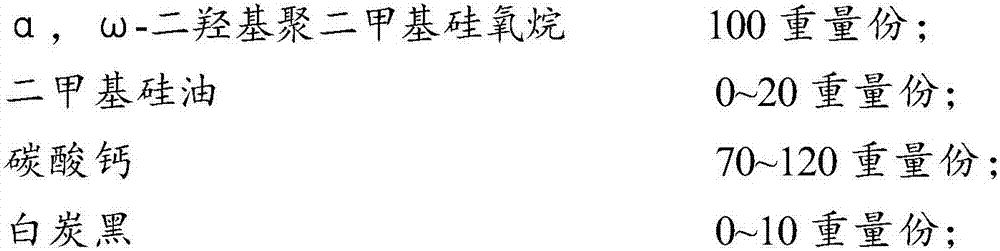

[0043] Mix α, ω-dihydroxy polydimethylsiloxane, dimethyl silicone oil, calcium carbonate and white carbon black, vacuum dehydrate after heating, and cool down to obtain component A;

[0044] Wherein, the temperature of the heating and stirring is preferably 100-150°C, more preferably 110-140°C. Next, the above mixture is subjected to vacuum dehydration, the pressure of the vacuum dehydration is preferably -0.09--0.1 MPa, and the time of the vacuum dehydration is preferably 2-4 hours.

[0045] Component B is prepared as follows:

[0046] The color paste, crosslinking agent, coupling agent, white carbon black and catalyst are mixed and reacted, and dehydrated in vacuum to obtain component B.

[0047] Specifically, first mix and sti...

Embodiment 1

[0051] A component: set the kinematic viscosity to 20000mm 2 / s α, ω-dihydroxy polydimethylsiloxane, nano-calcium carbonate treated with fatty acid, specific surface area 150m 2 / g fumed silica, kinematic viscosity 350mm 2 / s of simethicone oil is mixed, heated and stirred under vacuum conditions, and then vacuum dehydrated to obtain component A of a two-component silicone rubber sealant that adheres to the base material of the car lamp. The temperature of the heating and stirring is 130°C. Next, vacuum dehydration is carried out on the above mixture, the pressure of the vacuum dehydration is -0.09~-0.1MPa, and the time of the vacuum dehydration is 3 hours.

[0052] Component B: First, mix the black color paste (silicon oil and carbon black in a weight ratio of 3:1, under the conditions of heating temperature of 100-150°C and vacuum dehydration pressure of -0.09MPa~-0.1MPa, High-speed stirring and dispersing for 3-4 hours to obtain a black color paste), cross-linking agent ...

Embodiment 2

[0060] A component: set the kinematic viscosity to 80000mm 2 / s α, ω-dihydroxy polydimethylsiloxane, heavy calcium carbonate, specific surface area 150m 2 / g fumed silica, kinematic viscosity 50mm 2 / s of simethicone oil is mixed, heated and stirred under vacuum conditions, and then dehydrated to obtain component A of the two-component silicone rubber sealant that is adhesive to the base material of the car lamp. The temperature of the heating and stirring is 130°C. Next, vacuum dehydration is carried out on the above mixture, the pressure of the vacuum dehydration is -0.09~-0.1MPa, and the time of the vacuum dehydration is 3 hours.

[0061] Component B: First, mix and stir the black color paste (see Example 1 for the preparation method), the crosslinking agent methyltrimethoxysilane, and vinyltrimethoxysilane. After stirring for 10-20 minutes, disperse at a high speed for 30-40 minutes. After uniform, add coupling agent aminopropyltrimethoxysilane, γ-aminoethylaminopropylt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com