Method for manufacturing fructus jujubae vinegar

A production method, the technology of jujube vinegar, applied in the preparation of vinegar, methods based on microorganisms, biochemical equipment and methods, etc., can solve the problems of not strong jujube flavor, poor taste, heavy sour taste of raw jujube vinegar, etc., and achieve nutritional Full-bodied, soft sour, good-tasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

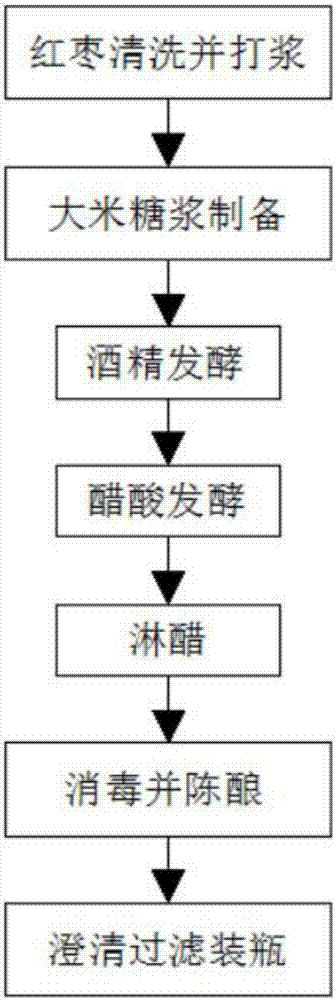

Image

Examples

Embodiment 1

[0023] A kind of preparation method of jujube vinegar, the specific steps of this method are as follows: wash the silt and impurities on the surface of jujube with flowing water, put the jujube in an oven and dry it for 0.5h, remove the jujube core after taking it out, and use a beater Beat the jujube meat into jujube pulp, add pure water to the jujube pulp, heat and simmer for 15 minutes, and set aside for later use; grind the rice soaked in pure water for 40 minutes into a slurry, add pure water to adjust the rice slurry to a concentration of 1.5g / ml, adjust the pH of the rice flour slurry to 6, then add α-amylase preparation, stir evenly, heat to 80°C and maintain it for 18 minutes, cool down to 60°C naturally, add fresh raw bran accounting for 2% of the total mass of the rice flour slurry for saccharification saccharification at 60°C for 3 hours to obtain rice syrup; add rice syrup to jujube syrup, and then inoculate 0.1% active dry yeast of Saccharomyces cerevisiae in a f...

Embodiment 2

[0025] A kind of preparation method of jujube vinegar, the specific steps of the method are as follows: wash the silt and impurities on the surface of the jujube with flowing water, put the jujube in an oven and dry it for 1 hour, remove the jujube core after taking it out, and grind the jujube with a beater Red jujube meat is made into jujube pulp, add pure water to the jujube pulp, heat and simmer for 20 minutes, and set aside for later use; grind the rice soaked in pure water for 50 minutes into a powder slurry, add pure water to adjust the rice flour slurry to a concentration of 1.5g / ml , adjust the pH of the rice slurry to 6.5, then add α-amylase preparation, stir evenly, heat to 90°C and maintain it for 20 minutes, cool down to 65°C naturally, add fresh bran saccharification agent accounting for 3% of the total mass of the rice slurry Keep warm at 65°C and saccharify for 4 hours to make rice syrup; add rice syrup to jujube syrup, then inoculate 0.3% Saccharomyces cerevisi...

Embodiment 3

[0027] A kind of preparation method of jujube vinegar, the specific steps of the method are as follows: wash the silt and impurities on the surface of the jujube with flowing water, put the jujube in an oven and dry it for 1 hour, remove the jujube core after taking it out, and grind the jujube with a beater Red jujube meat is beaten into jujube pulp, and pure water is added to the jujube pulp, heated and simmered for 18 minutes, and set aside for later use; the rice soaked in pure water for 45 minutes is ground into a powder slurry, and purified water is added to adjust the rice flour slurry to a concentration of 1.5g / ml , adjust the pH of the rice slurry to 6.3, then add α-amylase preparation, stir evenly, heat to 85°C and maintain it for 20 minutes, cool down to 63°C naturally, add fresh bran saccharification agent accounting for 2.5% of the total mass of the rice slurry Keep warm at 63°C and saccharify for 3 hours to make rice syrup; add rice syrup to jujube syrup, then ino...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com