High-wear-resisting flow guide type water nozzle body and manufacturing method thereof

A technology with high wear resistance and faucets, applied in valve details, valve housing structure, mechanical equipment, etc., can solve problems such as blockage, non-wear resistance, deformation, etc., and achieve the effect of streamline change obviously and streamline change rule

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

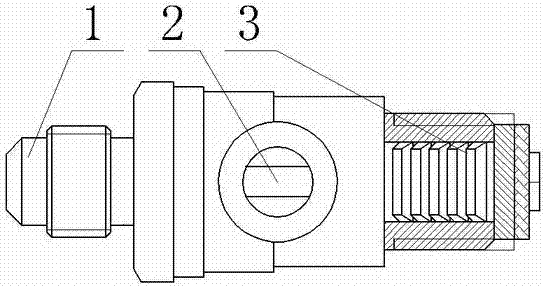

[0029] A high-wear-resistant flow-guiding faucet main body, which consists of a faucet main body 1 with a conical forging streamline concentrating toward the inner hole obtained through square-to-circle hot extrusion and swaging, and a faucet main body 1 that is arranged in the inner hole and shrinks with the faucet inner hole A diversion ring 3 with an acute-angle contour line at the mouth end, and a faucet valve 2 are also provided in the middle of the faucet main body 1 .

[0030] A method for manufacturing a high wear-resistant diversion nozzle body, comprising the following steps:

[0031] 1) Pre-preparation

[0032] ①Choose aluminum bronze copper billet as raw material;

[0033] ② Select forging equipment equipped with hydraulic generating device, rotary push device and air cooling device; select vacuum resistance furnace as initial forging heating equipment;

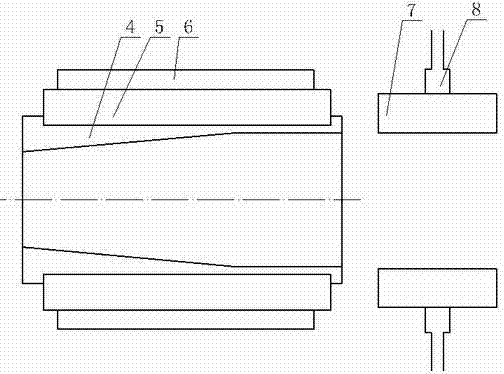

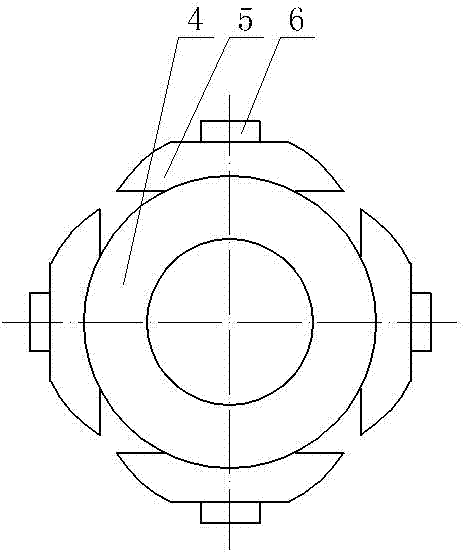

[0034] ③ Use four forged hammerheads 7 and matching hydraulic output device 8 as final forging and clamping t...

Embodiment 2

[0048] The whole is the same as Example 1, the difference is:

[0049] 2) forging

[0050]②The forging hammer head 7 linked with the rotary push device is pushed by the hydraulic generating device, and the copper billet is extruded into a forging billet with a nearly square cross section at a feed rate of about 5% for each deformation and a final deformation ratio of 45%;

[0051] ③Propel the forged billet with a nearly square cross-section at a speed of 0.25mm / s into the inner hole of the main body 4 of the ceramic tooling along the rotation axis on the basis of the joint rotation of the rotary push device and the forging hammer head 7;

[0052] ④ Install an air-cooling device at the outlet of the inner hole of the main body 4 of the ceramic tooling, and blow out nitrogen at a pressure of 3 bar for cooling;

[0053] ⑥Cool the forged copper billets within 10 minutes after forging at -75°C for 1.5 hours of ice-cooling treatment; then use 300°C for a time of (22d) min / mm based ...

Embodiment 3

[0058] 2) forging

[0059] ②The forging hammer head 7 linked with the rotary push device is pushed by the hydraulic pressure generating device, and the copper billet is extruded into a forging billet with a nearly square cross section at a feed rate of about 5% for each deformation and a final deformation ratio of 60%;

[0060] ③Propel the forged billet with a nearly square cross-section at a speed of 0.3mm / s into the inner hole of the main body 4 of the ceramic tooling along the rotation axis on the basis of the joint rotation of the rotary push device and the forging hammer 7;

[0061] ④ Install an air-cooling device at the outlet of the inner hole of the main body 4 of the ceramic tooling, and blow out nitrogen at a pressure of 5 bar for cooling;

[0062] ⑥Cool the forged copper billets within 10 minutes after forging at -85°C for 2 hours, and then temper them at 320°C for a time of (24d) min / mm based on the diameter of the copper billet. Forgings are required;

[0063] 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com