High-speed VCSEL laser epitaxial structure and preparation method therefor

An epitaxial structure and laser technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problems of affecting device reliability, increased photon scattering loss, fast oxidation rate, etc., to reduce intrinsic parasitic capacitance, reduce The effect of scattering loss and improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

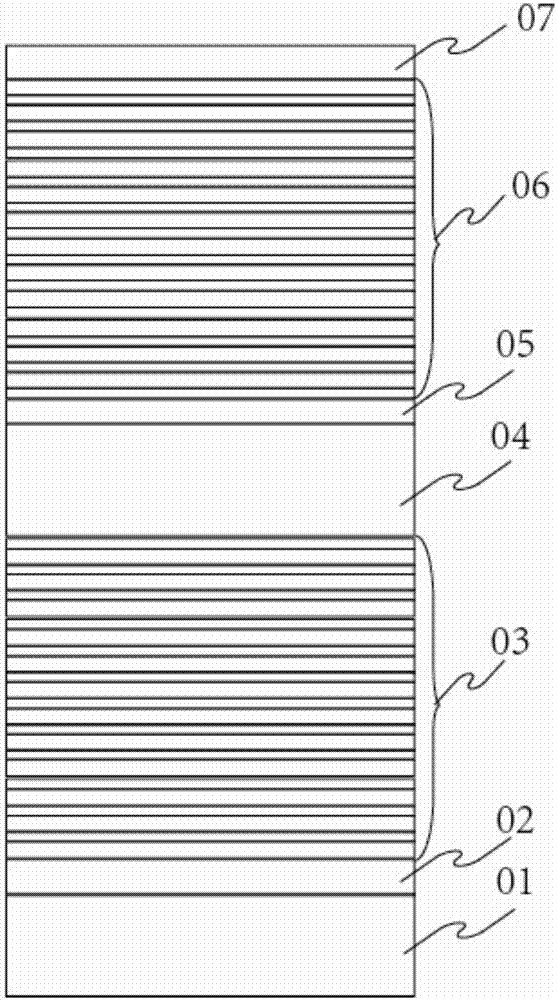

[0033] Such as figure 1 , 3 As shown, the present invention provides a high-speed VCSEL laser epitaxial structure, which includes a GaAs substrate 01, on which GaAs buffer layer 02, N-type doped DBR 03, active layer 04, oxide Confinement layer 05, P-type doped DBR06 and ohmic contact layer 07, in which the active layer 4 uses GaAs / AlGaAs MQW, and the oxidation confinement layer 05 is made of Al with multiple Ga components that can be adjusted freely 1-x Ga x As epitaxial layer composition, where X is the composition of Ga element. Multiple Al 1-x Ga x The Ga composition of the As epitaxial layer is preferably in a jump mode. The so-called jump means that the Ga composition of two adjacent epitaxial layers does not change continuously, but changes in a manner similar to a step function. As the most optimal way, multiple Al 1-x Ga x In the As epitaxial layer, the Ga component in the middle layer should be the smallest, the Ga component in the lowermost layer should be the...

Embodiment 2

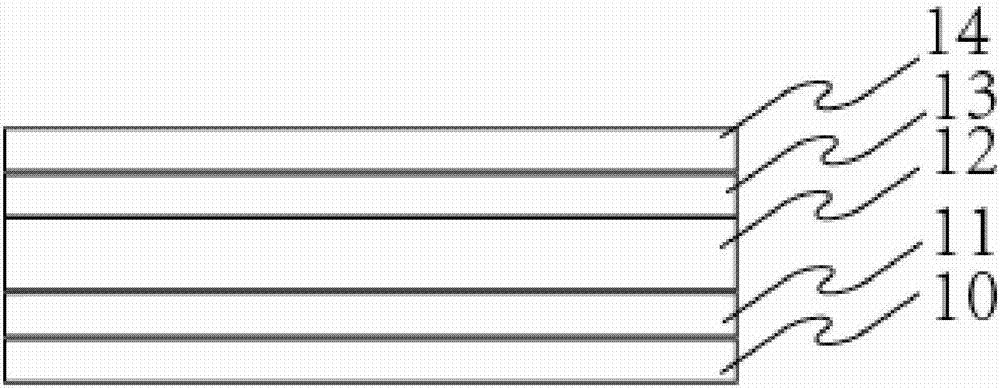

[0036] As a preferred method, the Ga composition of the middle epitaxial layer of the oxidation limiting layer is 2%, and the thickness is 10nm; the Ga composition of the lowermost and uppermost epitaxial layers is 5%, and the thickness is 5nm; The component is 2-5% and the thickness is 3-8nm. In this embodiment, the oxidation confinement layer comprises 5 nm Ga with 5% Al from bottom to top 0.95 Ga 0.05 As epitaxial layer, 3nmGa composition is 3% Al 0.97 Ga 0.03 As epitaxial layer, 10nm Ga with 2% Al 0.98 Ga 0.02 As epitaxial layer, 3nm Ga composition is 3% Al 0.97 Ga 0.03 As epitaxial layer and 5nm Ga composition with 5% Al 0.95 Ga 0.05 As epitaxial layer.

Embodiment 3

[0038] In this example, the oxidation confinement layer comprises 5nm Ga with 5% Al from bottom to top 0.95 Ga 0.05 As epitaxial layer, 8nmGa composition is 3% Al 0.97 Ga 0.03 As epitaxial layer, 10nm Ga with 2% Al 0.98 Ga 0.02 As epitaxial layer, 8nm Ga composition is 3% Al 0.97 Ga 0.03 As epitaxial layer and 5nm Ga composition with 5% Al 0.95 Ga 0.05 As epitaxial layer.

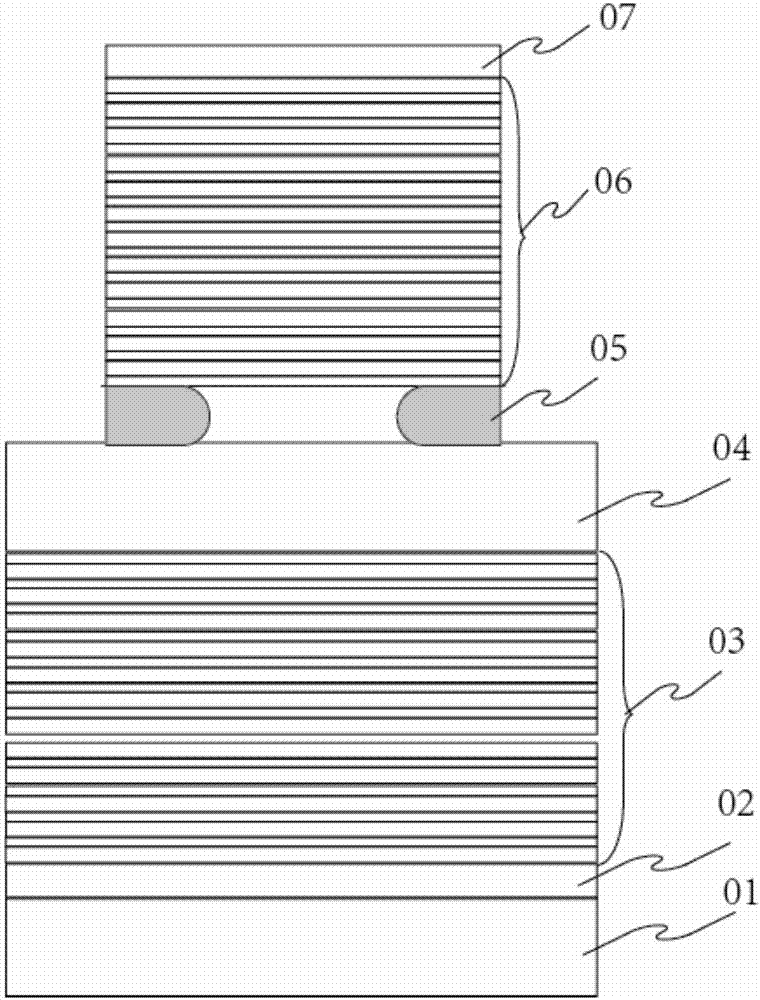

[0039] Oxidation limiting layer 05 adopts a composition hopping structure with a certain thickness. Due to the different oxidation rates of different Ga components, after it is fabricated into a VCSEL chip, its oxide layer morphology is as follows: Figure 4 shown.

[0040] In the chip process, the oxidation rate of AlGaAs increases with the decrease of the Ga composition. The oxidation limiting layer adopts AlGaAs, which has small stress and controllable oxidation rate. Therefore, compared with the traditional 30nm AlGaAs or AlAs oxidation limiting layer, the oxidation limiting layer The thicknes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com