Denitrification method and system of cement rotary kiln

A cement rotary kiln and denitrification technology, which is applied in the field of denitrification methods and denitrification systems, can solve the problems of short effective length of the reducing atmosphere area, achieve the effect of extending the stroke and improving the denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

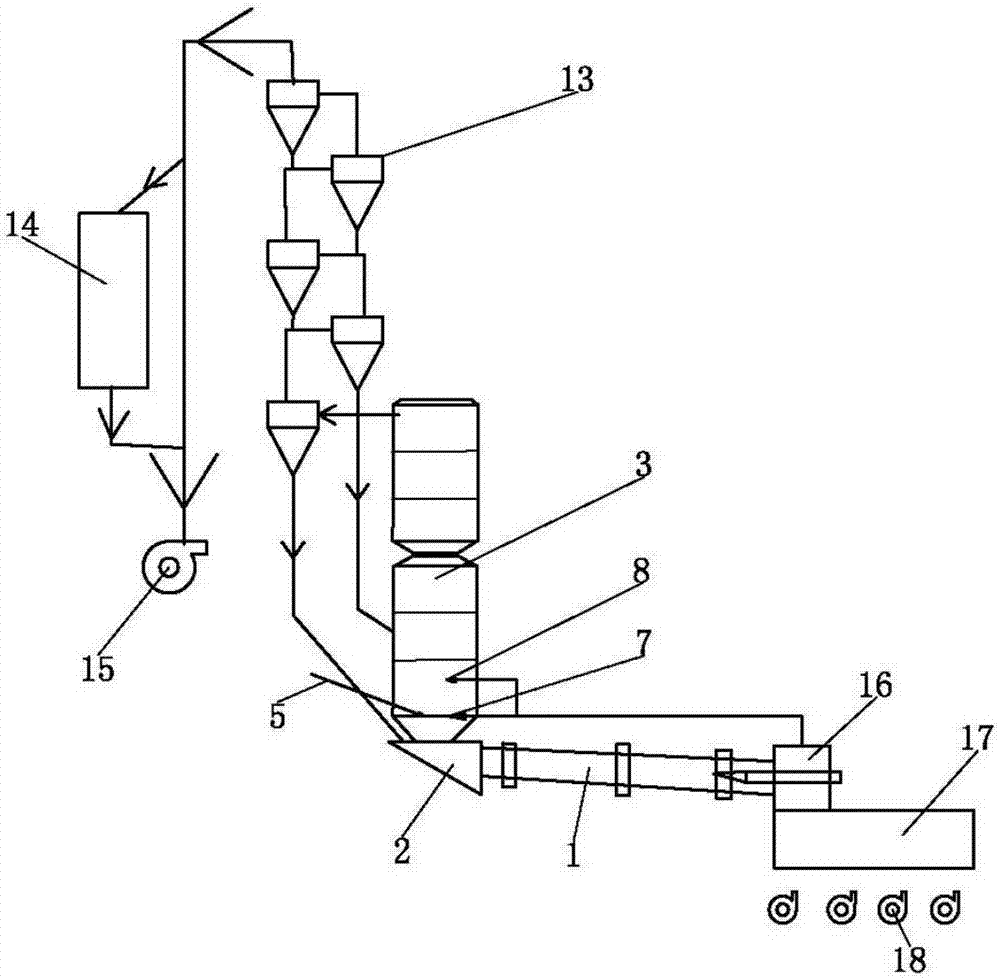

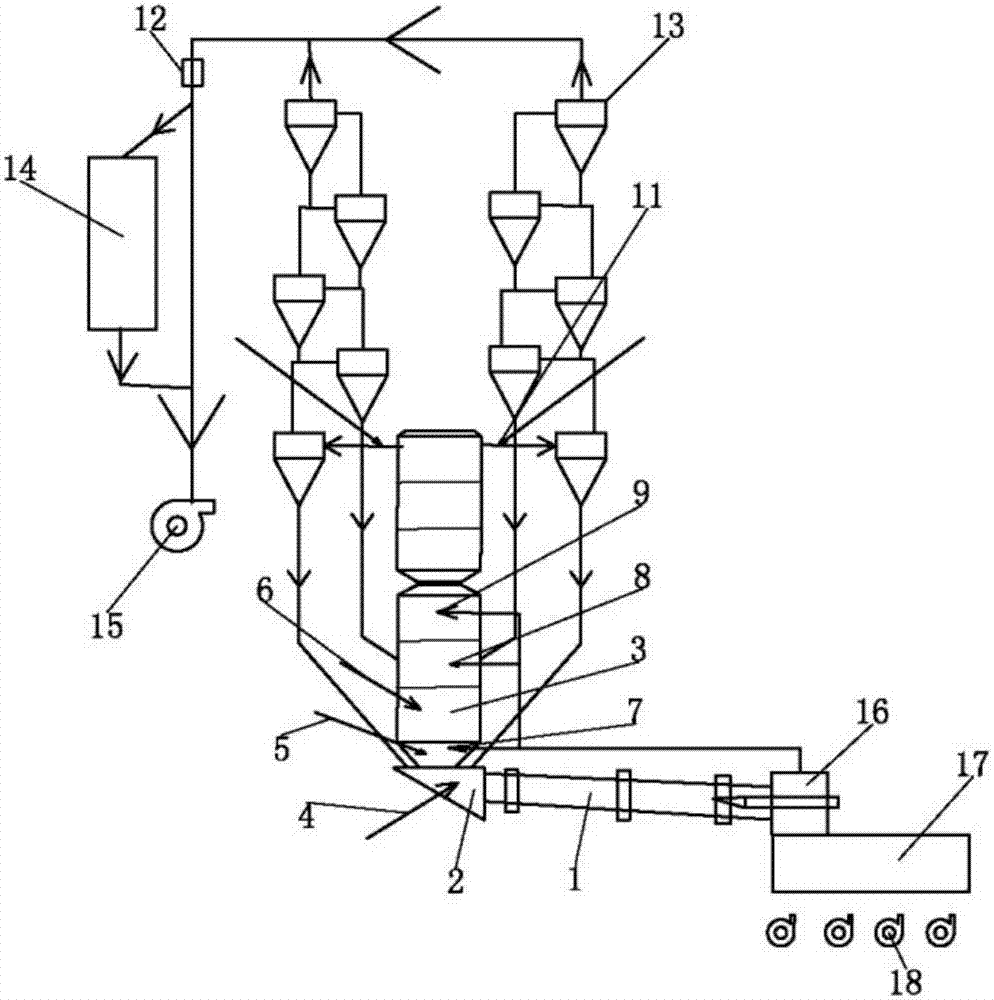

[0376] Such as figure 2 As shown, this embodiment provides a denitrification method for a cement rotary kiln. The fuel is delivered to the smoke chamber 2, and the fuel is burned to generate a reducing agent in a state of oxygen deficiency. The reducing agent forms a lower reducing atmosphere zone. The raw material that falls from the pyrolysis furnace 3 and enters the smoke chamber 2 is further heated, and the flue gas from the kiln tail of the rotary kiln 1 enters the smoke chamber 2, and the nitrogen oxides NO in the flue gas entering the smoke chamber 2 x A part of it is reduced and denitrated by the reducing agent in the lower reducing atmosphere area to generate harmless substances.

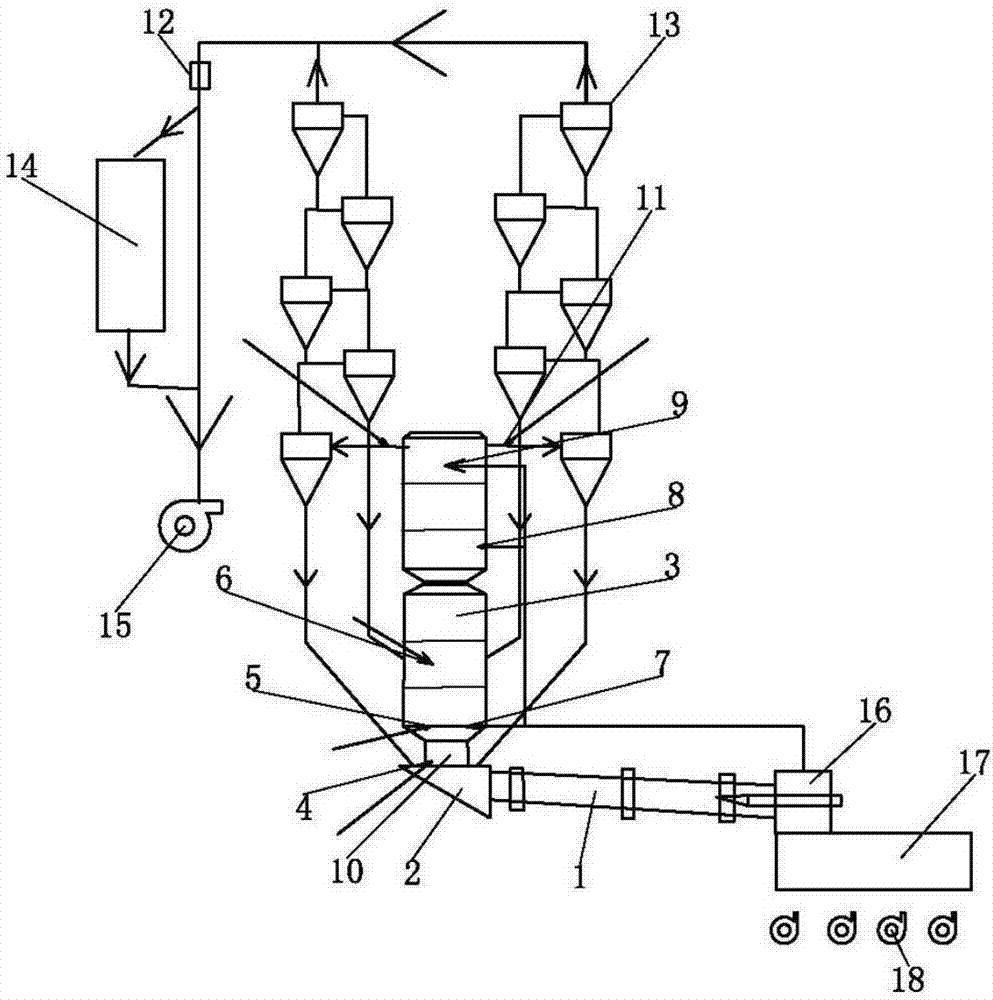

[0377] Of course, it can also be image 3 As shown, the fuel is delivered to the ascending flue 10, and the fuel is burned to generate a reducing agent in an oxygen-deficient state, and the reducing agent forms a lower reducing atmosphere zone. Further heating, the flue gas from the kiln...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com