Collagen-lysozyme antibacterial film and preparation method thereof

A technology of collagen and lysozyme, applied in biochemical equipment and methods, flexible coverings, packaging, etc., can solve problems such as complicated preparation methods, waste of time and energy, and limited storage period length, and achieve biophase Good capacity, saving time and energy, and extending the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

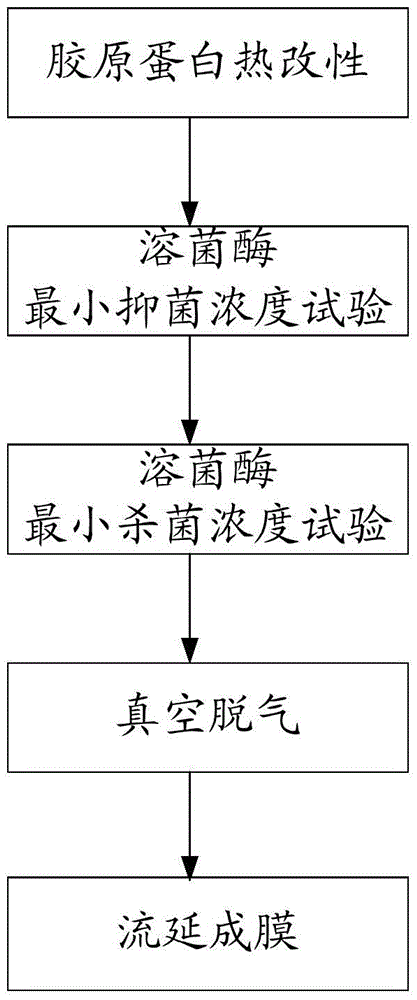

[0032] The first aspect of the present invention provides a kind of preparation method of collagen-lysozyme antibacterial membrane, comprises the following steps:

[0033] Take the modified collagen solution, dissolve lysozyme of different quality in the modified collagen solution respectively, after stirring evenly, obtain collagen-lysozyme blends with different lysozyme concentrations;

[0034] The minimum inhibitory concentration test of collagen-lysozyme blend was carried out to obtain the minimum inhibitory concentration of lysozyme;

[0035] The minimum bactericidal concentration test is carried out with the collagen-lysozyme blend having a minimum inhibitory concentration and a concentration greater than the minimum inhibitory concentration, to obtain the minimum bactericidal concentration of lysozyme;

[0036] Collagen-lysozyme blend liquid with the minimum bactericidal concentration and concentration close to the minimum bactericidal concentration is vacuum degassed, ...

Embodiment 1

[0078] refer to figure 1 A schematic flow chart of the preparation method, a preparation method of collagen-lysozyme antibacterial film, comprising the following steps:

[0079] (1) Thermal modification of collagen: Weigh 5g of fish scale collagen and dissolve it in 95mL of distilled water, the thermal modification temperature is 20°C, and the thermal modification time is 30min to obtain a modified collagen solution;

[0080] (2) The minimum inhibitory concentration test of lysozyme: take a certain amount of lysozyme, dissolve it in the modified collagen solution respectively, and the stirring speed is 2000r / min, and the final concentrations of lysozyme are respectively 100, 50, 25, 12.5 , 6.25, 3.13, 1.56, 0.78, 0.39, 0.195 and 0.098mg / mL collagen-lysozyme blend;

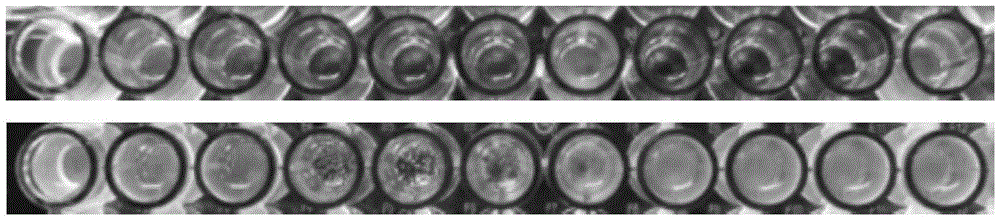

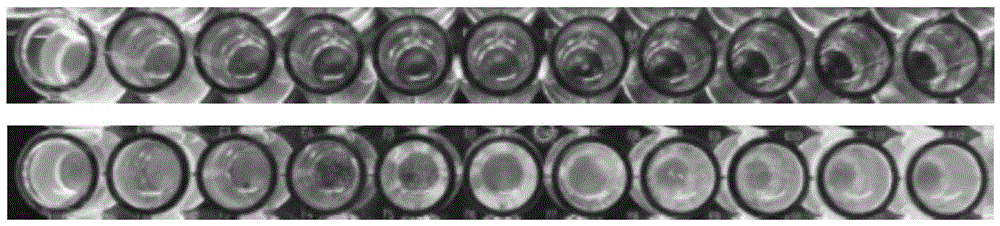

[0081] Take a sterile 96-well cell culture plate, place collagen-lysozyme blends with lysozyme concentrations of 100, 50, 25, 12.5, 6.25, 3.13, 1.56, 0.78, 0.39, 0.195 and 0.098 mg / mL respectively in Tubes 1 to 1...

Embodiment 2

[0087] A preparation method of collagen-lysozyme antibacterial film, comprising the following steps:

[0088] (1) Thermal modification of collagen: Weigh 3g of fish scale collagen and dissolve it in 97mL of distilled water, the thermal modification temperature is 60°C, and the thermal modification time is 5min to obtain a modified collagen solution;

[0089] (2) with the step (2) of embodiment 1;

[0090] (3) with the step (3) of embodiment 1;

[0091] (4) Vacuum degassing: Cool the collagen-lysozyme blend solution with a lysozyme concentration of 25mg / mL to room temperature (23°C), degas for 3min in a vacuum of 0.09Mpa, repeat three times, and then let it stand for 1h;

[0092] (5) Casting film formation: the collagen-lysozyme blend solution was fixed to 100mL, that is, 100mL vacuum degassed collagen-lysozyme blend solution with a lysozyme concentration of 25mg / mL was cast onto a plexiglass plate , Dry at 60°C for 4h, pay attention to keep the plexiglass plate level. After...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com