A kind of transformer oil moisture test paper, preparation and application

A technology for testing test paper and transformer oil, applied in the field of chemical detection, can solve problems such as unfavorable rapid detection, long detection time, cumbersome operation, etc., and achieve the effects of convenient and intuitive detection, long validity period, and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: Transformer oil moisture test paper, specifically prepared by the method comprising the following steps:

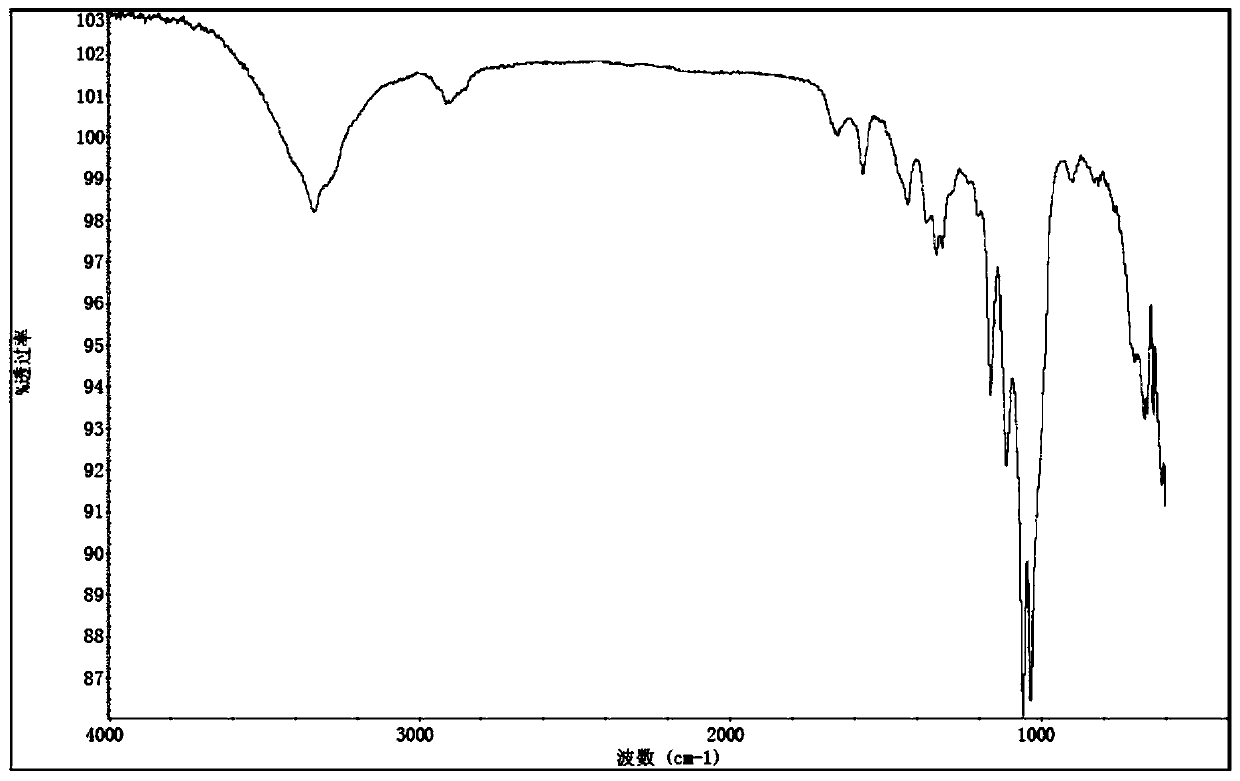

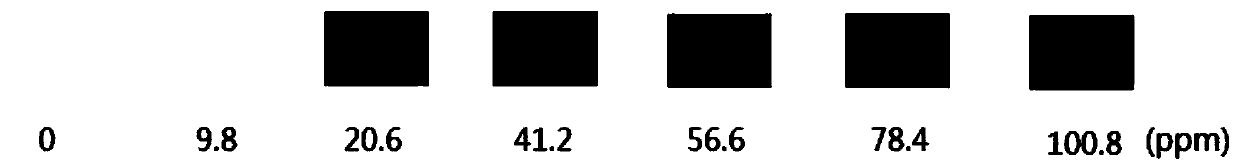

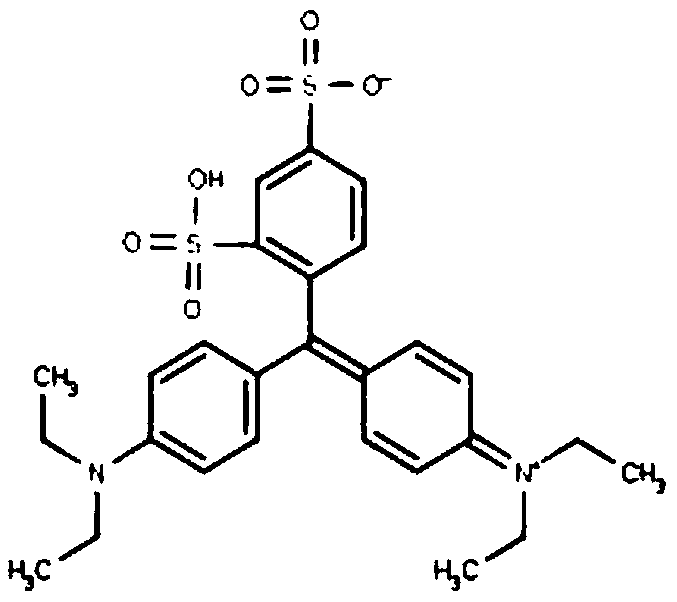

[0034] Step 1: Weigh 9 grams of copper sulfate, 9 grams of calcium sulfide and 5 grams of acid blue, grind them into powder in a mortar, and dry them in an oven at 80° C. to constant weight to remove water. The dried mixed powder was put into 200 ml of petroleum ether and continuously stirred to disperse evenly to obtain a color developer.

[0035] Step 2: Cut the cellulose paper sheet into paper sheets with a length of 8 cm and a width of 1 cm, and put them in an oven to dry at a temperature of 80° C. to a constant weight to remove moisture.

[0036] Step 3: Soak the dried cellulose paper in the color developer for 24 hours or more. If the soaking time is short, the color developer cannot be fully immersed in the cellulose paper. Put the soaked cellulose paper in a dry place. Store in the device for backup.

[0037] The prepared test paper is detec...

Embodiment 2

[0039] It should be noted that the above embodiments are the most preferred embodiments of the present invention, and do not limit the protection scope of the present invention. Embodiment 2: the judgment of test paper sensitivity

[0040] Soak the cellulose paper sheet prepared in Example 1 in the color developer, draw the transformer oil with a dropper, add about 5 milliliters of transformer oil dropwise on the test papers with different soaking times, and then compare the color changes of the test papers as shown in the table below :

[0041]

[0042]

[0043] It can be seen that the sensitivity of the test paper has a great relationship with the soaking time. When the soaking time reaches more than 24 hours, the test paper has better sensitivity.

Embodiment 3

[0044] Embodiment 3: Measure the transformer oil result comparison of different water contents

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com