Graphite conductive powder especially for improving conductivity of cable and preparation method

A technology of conductive powder and graphene, which is applied in the direction of cable/conductor manufacturing, circuit, electrical components, etc., can solve the problems of high cost, complex process, difficult to disperse graphene, etc., achieve simple use process, convenient use, and realize conductive performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

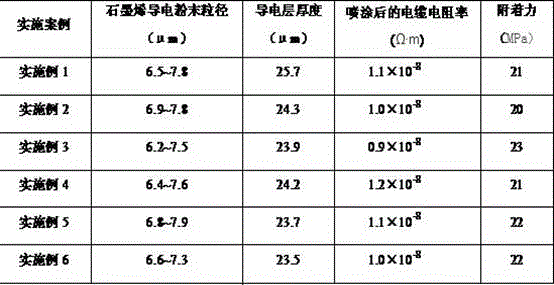

Examples

Embodiment 1

[0027] A graphene conductive powder specially used for improving the conductivity of cables and a preparation method thereof. The specific process of preparing graphene conductive powder and spraying on the surface of the cable core to form a conductive layer is as follows:

[0028] First, mix 200 g of tin powder and 250 g of anhydrous silver acetate to form an alloy for use. Disperse 20 g of graphene into 10 L of absolute ethanol and vibrate ultrasonically for 1 h to obtain a graphene dispersion. Add the above tin-silver alloy to the graphene dispersion, encapsulate the ball mill, and ball mill for 15 hours at a speed of 400r / min; place the above ball milled mixture in a mixer, add 20g of polyurethane, and heat to 75℃ and keep Constant temperature, while mechanical stirring at a speed of 80r / min. After the water content of the slurry is reduced to 40%, it is transferred to a vacuum oven for thorough drying; the dried composite powder is heated to the silver acetate decomposition...

Embodiment 2

[0031] First, 180g of tin powder and 200g of anhydrous silver acetate are mixed to form an alloy for use. Disperse 30 g of graphene into 10 L of absolute ethanol, and vibrate ultrasonically for 1.5 hours to obtain a graphene dispersion. Add the above tin-silver alloy to the graphene dispersion, encapsulate the ball mill, and ball mill for 10 hours at a speed of 600r / min; place the above ball milled mixture in a mixer, add 25g polyvinyl alcohol, and heat to 70°C And maintain a constant temperature, while mechanically stirring at a speed of 75r / min, after the water content of the slurry is reduced to 35%, transfer to a vacuum oven for thorough drying; heat the dried composite powder to the decomposition temperature of silver acetate, and keep it at a constant temperature 12min. The composite powder was then placed in a tube furnace, treated at 700°C in an argon atmosphere for 37 minutes, and a laser beam was applied at the same time. The graphene was completely uniformly welded ...

Embodiment 3

[0034] First, 200g of tin powder and 200g of anhydrous silver acetate are mixed to form an alloy for use. Disperse 40 g of graphene into 10 L of absolute ethanol, and vibrate ultrasonically for 1.3 hours to obtain a graphene dispersion. Add the above tin-silver alloy to the graphene dispersion, encapsulate the ball mill, and ball mill for 12h at a speed of 500r / min; place the above ball milled mixture in a mixer, add 30g of polyurethane, and heat to 80℃ and keep it Constant temperature, while mechanical stirring at a speed of 70r / min, after the water content of the slurry is reduced to 30%, it is transferred to a vacuum oven for thorough drying; the dried composite powder is heated to the silver acetate decomposition temperature and kept at a constant temperature for 18 minutes. The composite powder was then placed in a tube furnace, treated at 800°C in an argon atmosphere for 32 minutes, and a laser beam was applied at the same time. The graphene was completely uniformly welde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com