Method for co-producing silage and vegetable tanning agent by all components of banana stems and leaves

A technology of banana stem and leaf and vegetable tanning agent is applied in the field of agricultural waste resource utilization, and can solve the problems of reducing the nutritional quality of banana stem and leaf silage, increasing other raw material costs and labor costs, and perishable banana stem and leaf silage. , to achieve excellent overall quality, improve the quality of silage, and promote the effect of fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

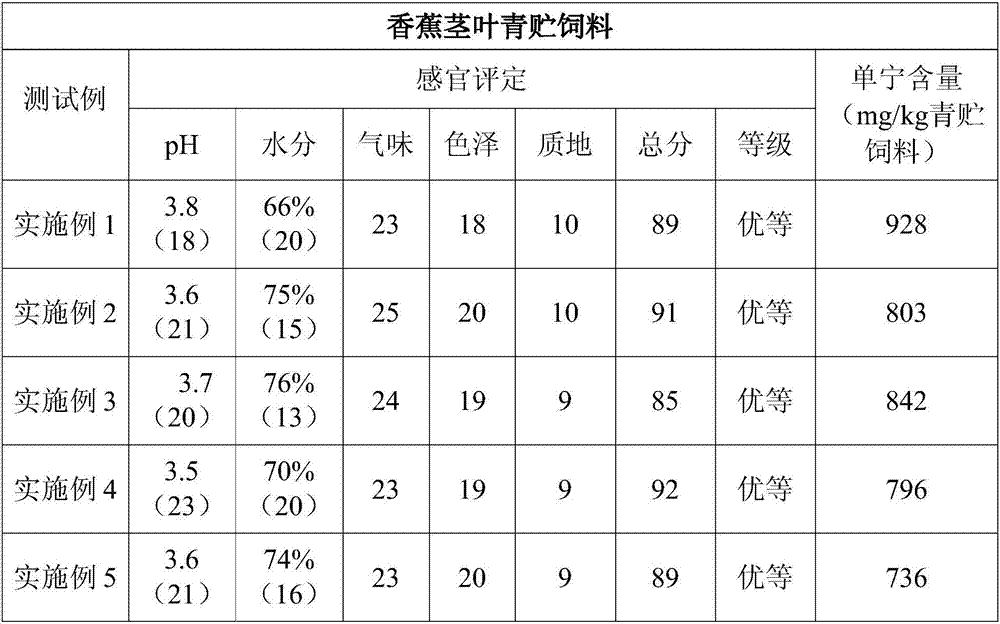

Embodiment 1

[0020] A method for co-producing silage and vegetable tanning agent with full components of banana stems and leaves, comprising the following steps:

[0021] (1) Crushing and pressing: first crush the whole banana stems and leaves to 2~5cm, add 6% rice husks by weight of the banana stems and leaves after crushing, and then squeeze them to a moisture content of about 60% by a double screw press, respectively Collect the solid residue and liquid residue of banana stems and leaves;

[0022] (2) Treatment of solid residue: first brewing glutinous rice and filtering off the glutinous rice wine to prepare wet distiller's grains; mixing lactic acid bacteria, tanninase, wet distiller's grains and citric acid to prepare a compound silage agent. The process is as follows, dissolving 5g of lactic acid bacteria In 1 liter of sugar water, each liter of sugar water contains 150 g of molasses. After sealed fermentation for 24 hours, add 5 g of tannase, 30 g of wet distiller’s grains and 35 g of c...

Embodiment 2

[0025] A method for co-producing silage and vegetable tanning agent with full components of banana stems and leaves, comprising the following steps:

[0026] (1) Crushing and pressing: first crush the whole banana stems and leaves to 2~5cm, after crushing, add 5% rice husks by weight of the banana stems and leaves, and then squeeze them with a double screw press to a moisture content of about 70%, respectively Collect the solid residue and liquid residue of banana stems and leaves;

[0027] (2) Treatment of solid residue: firstly brew the glutinous rice and filter the glutinous rice wine to obtain wet distiller's grains; mix lactic acid bacteria, tanninase, wet distiller's grains and citric acid uniformly to prepare a compound silage agent. The process is as follows, dissolve 2g of lactic acid bacteria In 1 liter of sugar water, each liter of sugar water contains 160g of molasses. After sealed fermentation for 24 hours, add 15g of tannase, 20g of wet distiller’s grains and 25g of c...

Embodiment 3

[0030] A method for co-producing silage and vegetable tanning agent with full components of banana stems and leaves, comprising the following steps:

[0031] (1) Crushing and pressing: first crush the whole banana stems and leaves to 2~5cm, add rice husks of 4% by weight of banana stems and leaves after crushing, and then squeeze them to about 75% moisture content by double screw press, respectively Collect the solid residue and liquid residue of banana stems and leaves;

[0032] (2) Treatment of solid residue: firstly brew the glutinous rice and filter the glutinous rice wine to obtain wet distiller's grains; mix lactic acid bacteria, tanninase, wet distiller's grains and citric acid uniformly to prepare a compound silage agent. The process is as follows, dissolve 2g of lactic acid bacteria In 0.5 liter of sugar water, each liter of sugar water contains 140g of molasses. After sealed fermentation for 24 hours, add 5g of tannase, 20g of wet distiller’s grains and 25g of citric acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com