A kind of ruthenium series ammonia synthesis catalyst and preparation method thereof

A kind of ammonia synthesis and catalyst technology, which is applied in the direction of ammonia preparation/separation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low ammonia synthesis activity and poor stability of ruthenium-based ammonia synthesis catalysts, etc. Effects of synthetic activity, resistance to methanation, and high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

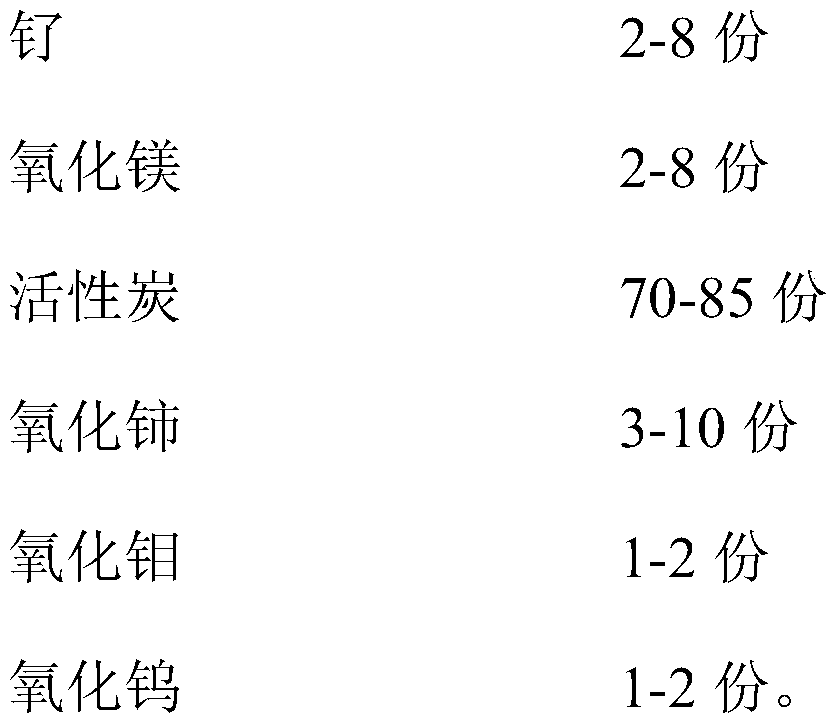

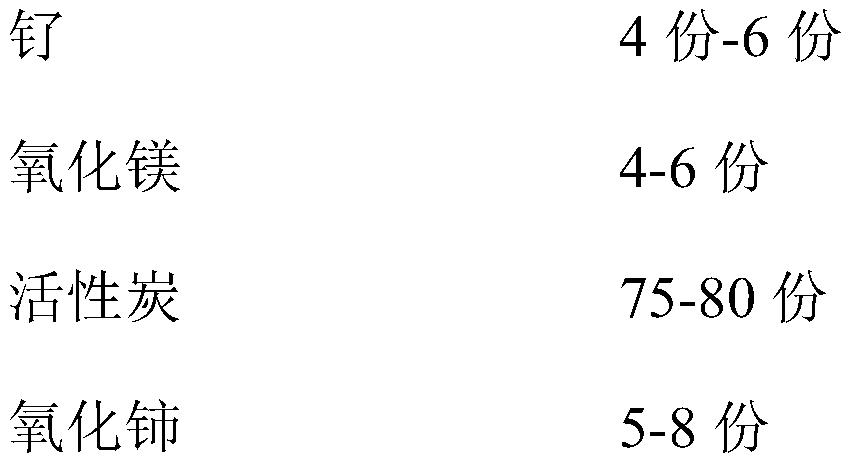

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides a ruthenium-based ammonia synthesis catalyst and a preparation method thereof. The ruthenium-based ammonia synthesis catalyst consists of 5g of ruthenium, 5g of magnesium oxide, 80g of activated carbon, 7g of cerium oxide, 1.5g of molybdenum oxide and 1.5g of tungsten oxide;

[0038] The preparation method of above-mentioned ruthenium series ammonia synthesis catalyst comprises the steps:

[0039] 1) Mix basic magnesium carbonate, activated carbon, basic cerium carbonate, molybdenum oxide and tungsten oxide ball mill, collect a mixture with a particle size of 0.1mm, and add a binder-epoxy resin to the mixture for molding, get moldings;

[0040] 2) Immerse the molded product in equal volumes in an aqueous solution of potassium ruthenate with a mass fraction of 12%, control the temperature of the immersion to 25° C., and take it out after the immersion is completed;

[0041] 3) Reducing the impregnated molded product in hydrogen, controlling the...

Embodiment 2

[0044] This embodiment provides a ruthenium-based ammonia synthesis catalyst and a preparation method thereof. The ruthenium-based ammonia synthesis catalyst consists of 2g of ruthenium, 8g of magnesium oxide, 70g of activated carbon, 3g of cerium oxide, 2g of molybdenum oxide and 1g of tungsten oxide;

[0045] The preparation method of above-mentioned ruthenium series ammonia synthesis catalyst comprises the steps:

[0046] 1) Mix basic magnesium carbonate, activated carbon, basic cerium carbonate, molybdenum oxide and tungsten oxide by ball milling, collect a mixture with a particle size of 0.05mm, and shape the mixture to obtain a molded product;

[0047] 2) Immerse the molded product in an equal volume in an aqueous solution of sodium ruthenate with a mass fraction of 8%, control the temperature of the immersion to 40° C., and take it out after the immersion is completed;

[0048]3) Reducing the impregnated molded product in hydrogen, controlling the reduction temperature...

Embodiment 3

[0051] This embodiment provides a ruthenium-based ammonia synthesis catalyst and a preparation method thereof. The ruthenium-based ammonia synthesis catalyst consists of 8g of ruthenium, 2g of magnesium oxide, 85g of gac, 3g of cerium oxide, 1g of molybdenum oxide and 2g of tungsten oxide;

[0052] The preparation method of above-mentioned ruthenium series ammonia synthesis catalyst comprises the steps:

[0053] 1) Mix basic magnesium carbonate, activated carbon, basic cerium carbonate, molybdenum oxide and tungsten oxide by ball milling, collect a mixture with a particle size of 0.5 mm, and shape the mixture to obtain a molded product;

[0054] 2) Immerse the molded product in equal volumes in an aqueous solution of potassium ruthenate with a mass fraction of 15%, control the temperature of the immersion to 10° C., and take it out after the immersion is completed;

[0055] 3) Reducing the impregnated molded product in hydrogen, controlling the reduction temperature to 400°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com