Light-free formaldehyde removal catalyst, formaldehyde removal system containing catalyst and purpose thereof

A catalyst and system technology, applied in the environmental field, can solve the problems of product toxicity, pollution hazards, etc., and achieve the effect of solving the problem of aldehyde removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

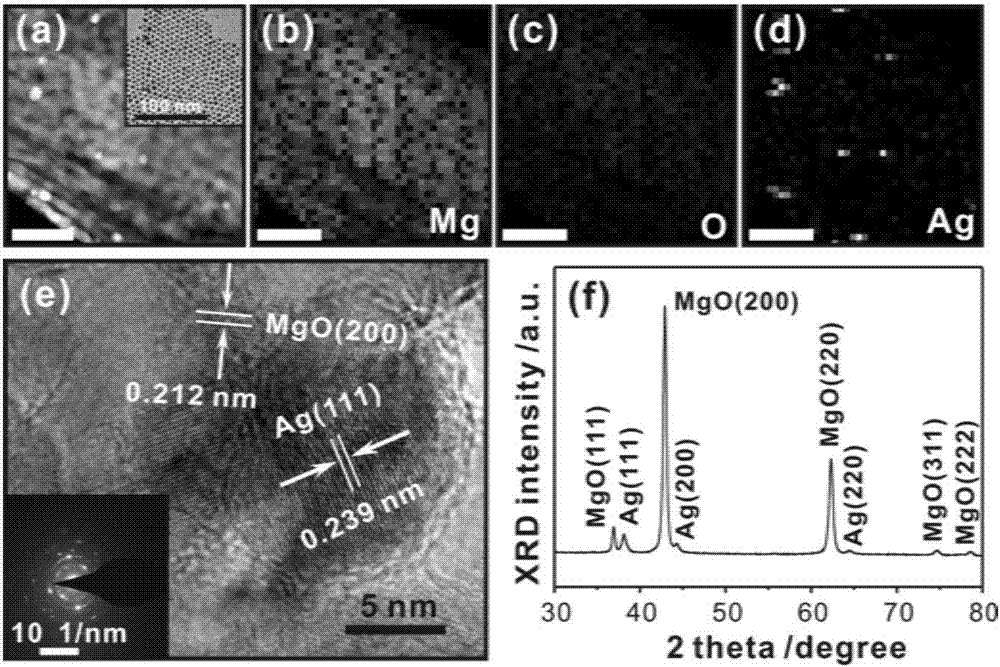

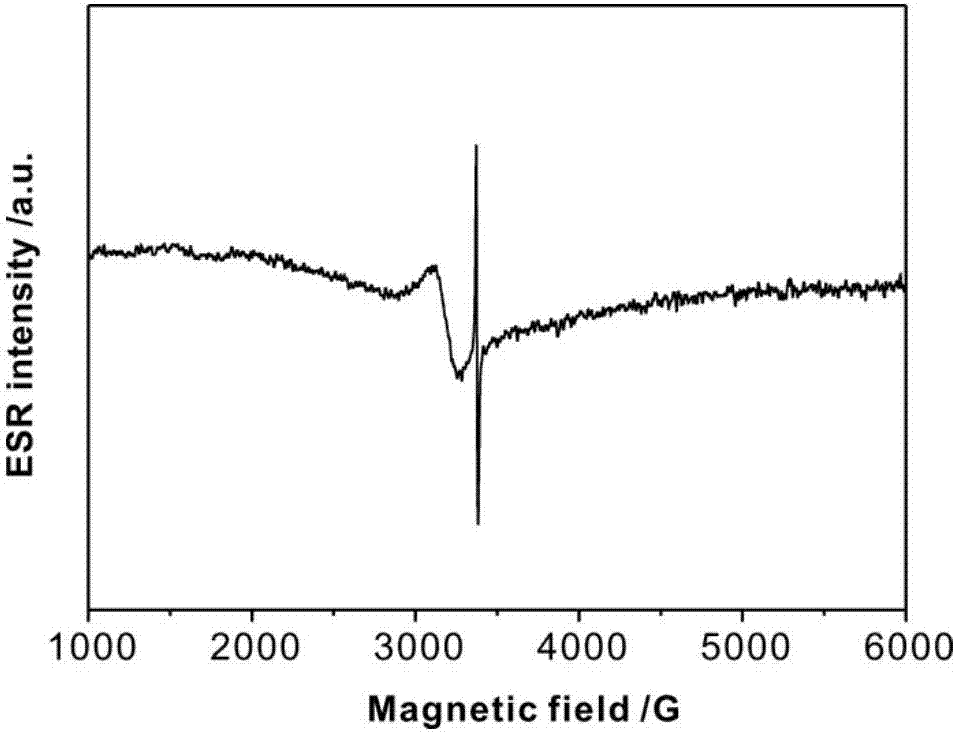

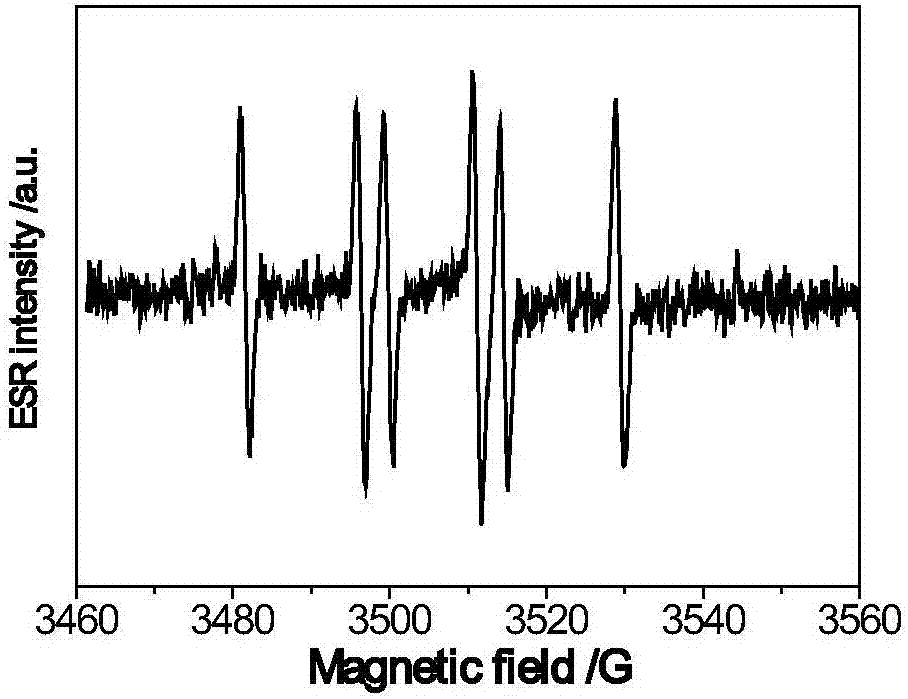

[0075] In this example, an Ag / MgO catalyst is prepared by taking the transition metal as Ag and the basic carrier as MgO as an example to illustrate the non-light aldehyde removal catalyst involved in the present invention. The preparation method of the catalyst is as follows: add 11 mg of silver nitrate to 15 ml of oleylamine solution, stir at 90 degrees for 1 hour, add 120 mg of tert-butylboramine borane as a reducing agent, and adjust the reaction temperature to 120 degrees , reacted for 3 hours, cooled to room temperature, added absolute ethanol to precipitate and washed, centrifuged and dried to obtain Ag nanoparticles. Then the prepared Ag nanoparticles were dissolved in chloroform to form a 1mol / L solution, and then the MgO solid powder was added into the chloroform solution, and stirred and adsorbed at room temperature for 2-5 hours. When the adsorption equilibrium is reached, the stirring is stopped and the solution is allowed to stand still for about 10 minutes, then...

Embodiment 2

[0080] Add 20 mg of chloroplatinic acid into 10 ml of oleylamine solution, stir at 100 degrees for 1 hour, add 220 mg of tert-butylboramine borane as a reducing agent, adjust the reaction temperature to 120 degrees, react for 4 hours and then cool to room temperature, add absolute ethanol to precipitate and wash, and obtain Pt nanoparticles after centrifugation and drying. Then the prepared Pt nanoparticles are dissolved in chloroform to form a 1mol / L solution, and then the MgO solid powder is added into the chloroform solution, and stirred and adsorbed at room temperature for 2-5 hours. When the adsorption equilibrium is reached, the stirring is stopped and the solution is left to stand for about 20 minutes, then the above-mentioned adsorbed precipitate is vacuum-dried, and finally calcined at 500° C., and the size distribution of the obtained Pt nanoparticles is 5-50 nm.

[0081] The above-prepared Pt / MgO catalyst was placed in a solution of DMPO trapping agent containing fo...

Embodiment 3

[0083] 20 milligrams of chloroplatinic acid and 10 milligrams of silver nitrate were added to 20 milliliters of oleylamine solution, and after stirring at 100 degrees for 1 hour, 340 milligrams of tert-butylboramine borane was added as a reducing agent, and the reaction temperature was adjusted to 120 degrees. After reacting for 4 hours, cool to room temperature, add absolute ethanol to precipitate and wash, and obtain PtAg nano-alloy particles after centrifuging and drying, with a particle size of about 10 nm. Then the prepared PtAg nano-alloy particles are dissolved in chloroform to form a 1mol / L solution, and then the MgO solid powder is added into the above-mentioned chloroform solution, and stirred and adsorbed at room temperature for 2-5 hours. When the adsorption equilibrium is reached, the stirring is stopped and the solution is left to stand for about 20 minutes, then the above-mentioned adsorbed precipitate is vacuum-dried, and finally calcined at 500° C., and the siz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com