Small bell type Fe3O4 nano-reactor, and preparation and application of nano-reactor

A nano-reactor and bell-shaped technology, which is applied in the field of preparation of bell-shaped nano-reactors, can solve the problems of poor stability and low catalytic activity, and achieve the effect of avoiding agglomeration and enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: bell type Fe of the present invention 3 o 4 Preparation method of nanoreactor

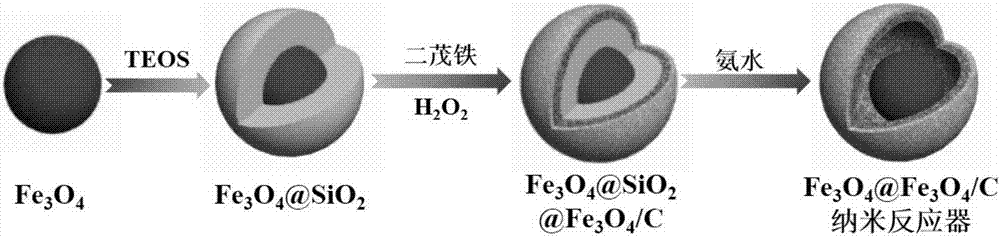

[0025] The core-shell provided by the present invention is Fe 3 o 4 Fe 3 o 4 @Fe 3 o 4 / C, the synthesis schematic is as follows figure 1 As shown, its specific preparation method can be divided into the following four steps:

[0026] (1) Preparation of Fe 3 o 4 Magnetic particles: 2.60g FeCl 3 ·6H 2 O. Dissolve 1.35g of sodium citrate and 4.80g of sodium acetate in 80mL of ethylene glycol, and magnetically stir at room temperature for half an hour. The obtained yellow mixed solution was immediately transferred into a closed polytetrafluoroethylene-lined stainless steel high-temperature and high-pressure reactor, and heated to 200° C. in a muffle furnace for 10 hours of reaction. After the reaction, the black product was magnetically separated, washed three times with ethanol and deionized water, and dried in vacuum for 12 hours to obtain Fe 3 o 4 Magnetic partic...

Embodiment 2

[0030] Embodiment 2: bell type Fe of the present invention 3 o 4 Structural Characterization of Nanoreactors

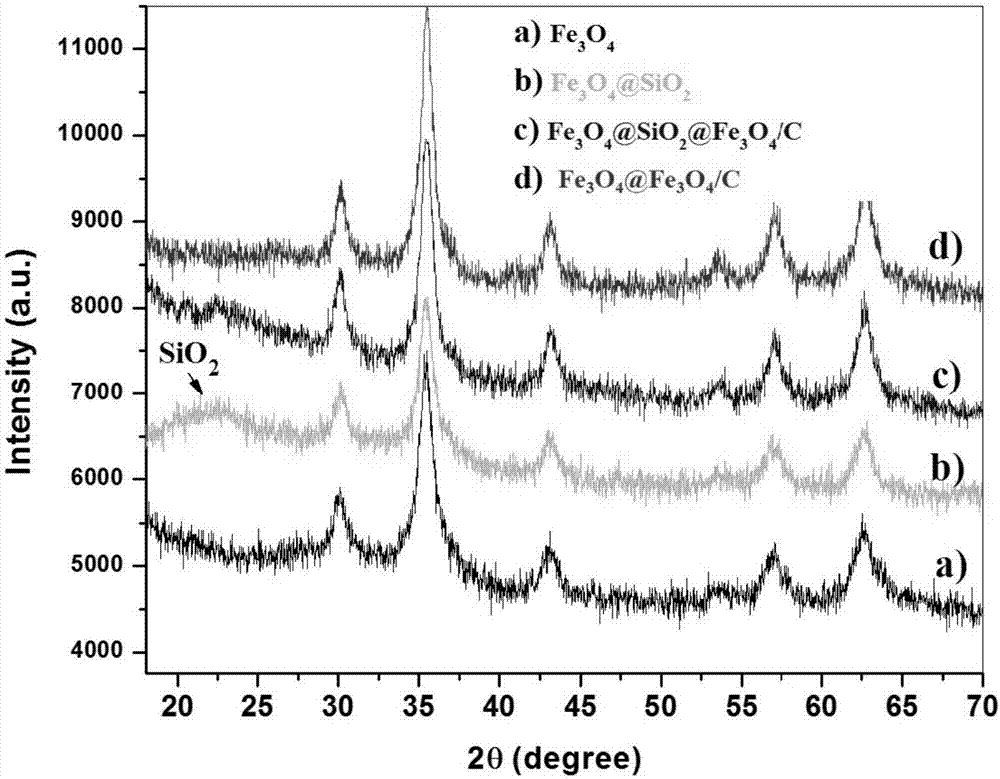

[0031] For the Fe prepared in Example 1 3 o 4 The structure of the nanoreactor was characterized as follows:

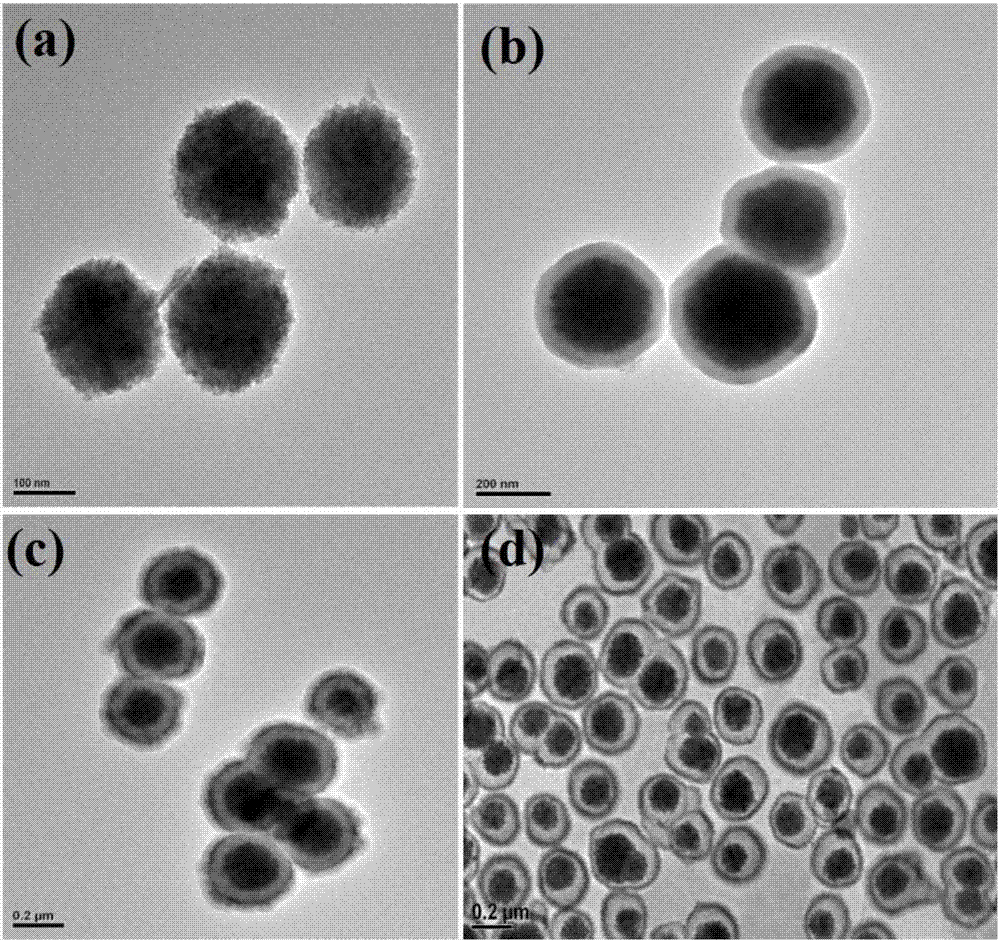

[0032] (1) Morphological characterization

[0033] The as-prepared Fe was observed by transmission electron microscopy (TEM) 3 o 4 , Fe 3 o 4 @SiO 2 , Fe 3 o 4 @SiO 2 @Fe 3 o 4 / C and bell type Fe 3 o 4 @Fe 3 o 4 / C nanoreactor morphology, the results are as figure 2 shown. Fe 3 o 4 The particle size is uniform, the edge is slightly rough, and the average particle size is about 200nm. After coating with a layer of silica gel with a thickness of about 40nm, it presents an obvious core-shell structure, and the edges become smoother. in H 2 o 2 Under the action of ferrocene and ferrocene, a special double-layer shell structure grows on the surface of the silica gel shell, which consists of Fe in the inner ring 3 o 4 layer and the carb...

Embodiment 3

[0039] Embodiment 3: adopt heterogeneous phase Fenton treatment method to remove 4-chlorophenol in the aqueous solution

[0040] Fe 3 o 4 Magnetic particles, Fe 3 o 4 @Fe 3 o 4 The preparation process of / C reactor is with example 1. In this example, 4-chlorophenol is used as a representative organic pollutant to investigate Fe 3 o 4 @Fe 3 o 4 / C reactor catalytic decomposition of H 2 o 2 Ability to oxidize 4-chlorophenol.

[0041] The degradation experiment was carried out in a 50mL Erlenmeyer flask, and Fe 3 o 4 @Fe 3 o 4 / C catalyst (final concentration is 0.5g / L in waste water volume, under the same condition with Fe 3 o 4 magnetic particles as a control), and then add mass concentration of 30% H 2 o 2 (The final concentration is 20mM in terms of waste water volume) to activate the catalytic degradation reaction, and take out part of the reaction solution to measure the concentration of 4-chlorophenol at regular intervals. The reaction flask was placed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com