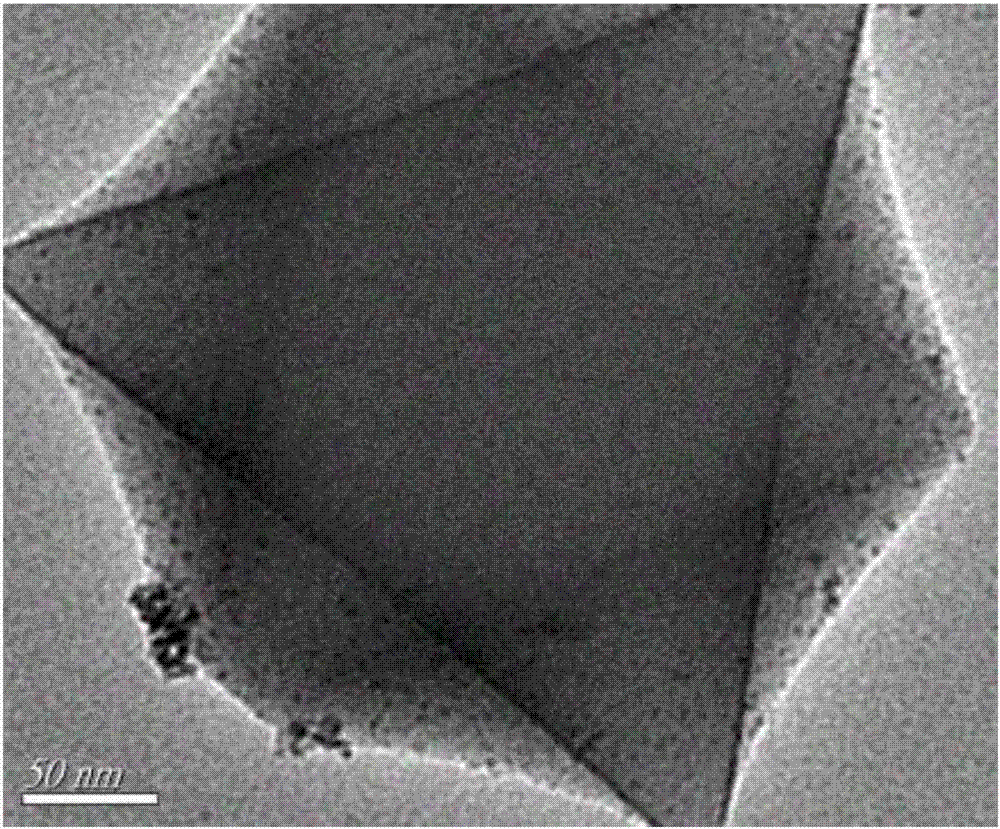

Method for preparing nano-doping metal organic framework with photocatalytic performance

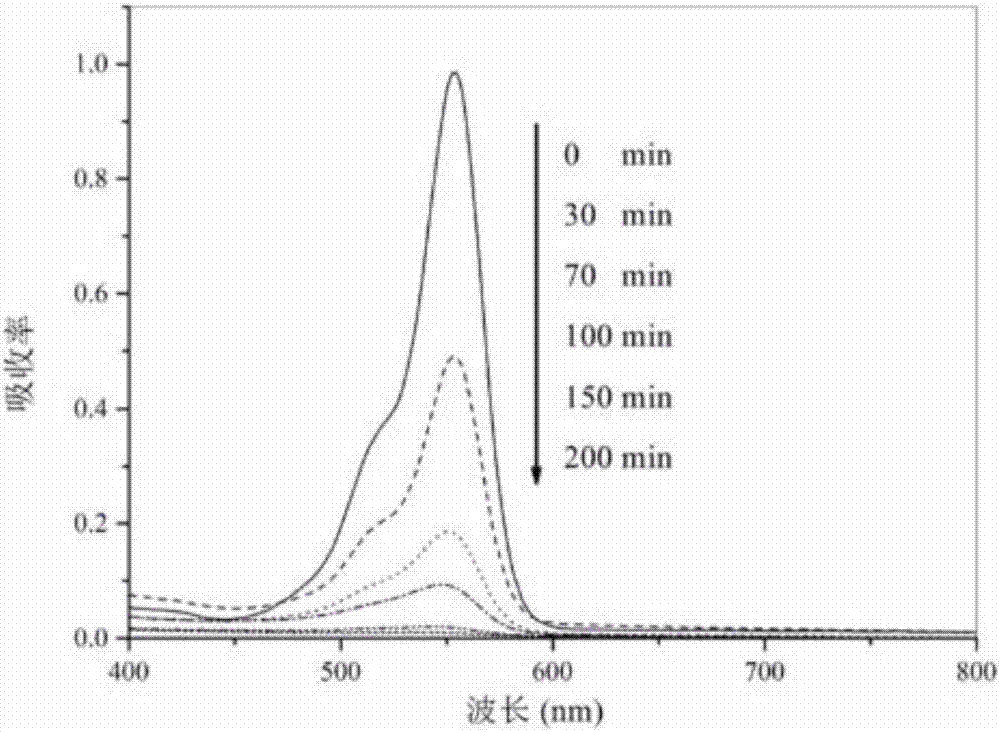

A metal-organic framework, photocatalytic technology, applied in chemical instruments and methods, separation methods, chemical/physical processes, etc., can solve the problems of easy deactivation and low quantum efficiency, and achieve low cost, good specific surface area, composite light The effect of improving catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing a nano-doped metal-organic framework with photocatalytic properties, the steps are as follows:

[0030] Step 1, adding polyvinylpyrrolidone into absolute ethanol for ultrasonication in a water bath until completely dissolved, then adding a stabilizer, adding n-butyl titanate dropwise, sealing and heating for 3 hours to obtain a nano-titanium dioxide sol solution wrapped in polyvinylpyrrolidone;

[0031] Step 2, adding ethyl silicate into the nano-titanium dioxide sol, sealing the micro-ultrasonic reaction for 1 hour, naturally cooling and then distilling under reduced pressure to obtain silicon nano-doped titanium dioxide colloid;

[0032] Step 3, adding ferric chloride and terephthalic acid to absolute ethanol, slowly adding acetic acid dropwise, after the dropwise addition, conduct a sealed reflux reaction for 2 hours, then leave to react for 8 hours, and obtain a suspension with precipitation after natural cooling;

[0033] Step 4, the suspensi...

Embodiment 2

[0045] A method for preparing a nano-doped metal-organic framework with photocatalytic properties, the steps are as follows:

[0046] Step 1, adding polyvinylpyrrolidone to absolute ethanol for ultrasonication in a water bath until it is completely dissolved, then adding a stabilizer, adding n-butyl titanate dropwise, sealing and heating for 5 hours to obtain a nano-titanium dioxide sol solution wrapped in polyvinylpyrrolidone;

[0047] Step 2, adding ethyl silicate into the nano-titanium dioxide sol, sealing the micro-ultrasonic reaction for 2 hours, naturally cooling and then distilling under reduced pressure to obtain silicon nano-doped titanium dioxide colloid;

[0048] Step 3, adding ferric chloride and terephthalic acid to absolute ethanol, slowly adding acetic acid dropwise, performing a sealed reflux reaction for 8 hours after the dropwise addition, then standing for reaction for 14 hours, and obtaining a suspension with precipitation after natural cooling;

[0049] St...

Embodiment 3

[0060] A method for preparing a nano-doped metal-organic framework with photocatalytic properties, the steps are as follows:

[0061] Step 1, adding polyvinylpyrrolidone to absolute ethanol in a water bath and ultrasonically until it is completely dissolved, then adding a stabilizer, adding n-butyl titanate dropwise, sealing and heating for 4 hours to obtain a nano-titanium dioxide sol solution wrapped in polyvinylpyrrolidone;

[0062] Step 2, adding ethyl silicate into the nano-titanium dioxide sol, sealing the micro-ultrasonic reaction for 2 hours, naturally cooling and then distilling under reduced pressure to obtain silicon nano-doped titanium dioxide colloid;

[0063] Step 3, adding ferric chloride and terephthalic acid to absolute ethanol, slowly adding acetic acid dropwise, performing a sealed reflux reaction for 5 hours after the dropwise addition, and then standing for reaction for 12 hours, and obtaining a suspension with precipitation after natural cooling;

[0064]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com