Physalis alkekengi persistent calyx bio-based carbon material and preparation method thereof

A technology of Physalis persistent calyx and bio-based carbon, which is applied in the field of carbon materials and its preparation, and achieves the effects of no pollution to the environment, wide sources of raw materials, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

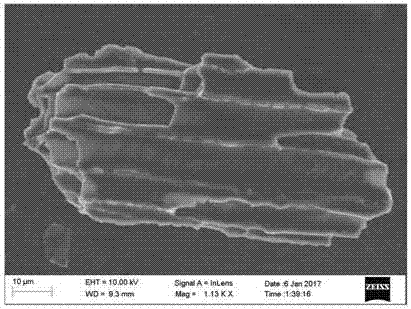

[0022] (1) Wash the persistent calyx of Physalis berry, soak it in 6mol / L NaOH aqueous solution for 24h, then wash it with distilled water and dry it to obtain the biomass precursor of Physalis persistent calyx.

[0023] (2) Physalis persistent calyx biomass precursor prepared in step (1) was placed in N 2 Under protection, it was cracked and carbonized at 700°C for 3 hours, and a bio-based carbon material of Physalis physalis was prepared.

Embodiment 2

[0025] (1) Wash the persistent calyx of Physalis berry, soak it in 6mol / L HCl aqueous solution for 24h, then wash it with distilled water and dry it to obtain the biomass precursor of Physalis persistent calyx.

[0026] (2) Physalis persistent calyx biomass precursor prepared in step (1) was placed in N 2 Under protection, it was cracked and carbonized at 700°C for 3 hours, and a bio-based carbon material of Physalis physalis was prepared.

Embodiment 3

[0028] (1) Wash the persistent calyx of Physalis berry, soak it in 4mol / L HCl aqueous solution for 8h, wash it with distilled water, then soak it in 6mol / L NaOH aqueous solution for 8h, then wash it with distilled water and dry it to get Physalis sinensis Calyx biomass precursors.

[0029] (2) Physalis persistent calyx biomass precursor prepared in step (1) was placed in N 2 Under protection, it was cracked and carbonized at 550°C for 2 hours, and a bio-based carbon material of Physalis physalis was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com