Preparation apparatus of anhydrous sodium sulphate

A technology of Yuanming powder and equipment, applied in the direction of alkali metal sulfite/sulfite, alkali metal compound, inorganic chemistry, etc. The effect of crystallization speed, full recycling and fast transmission speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be described in detail below in conjunction with embodiments. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

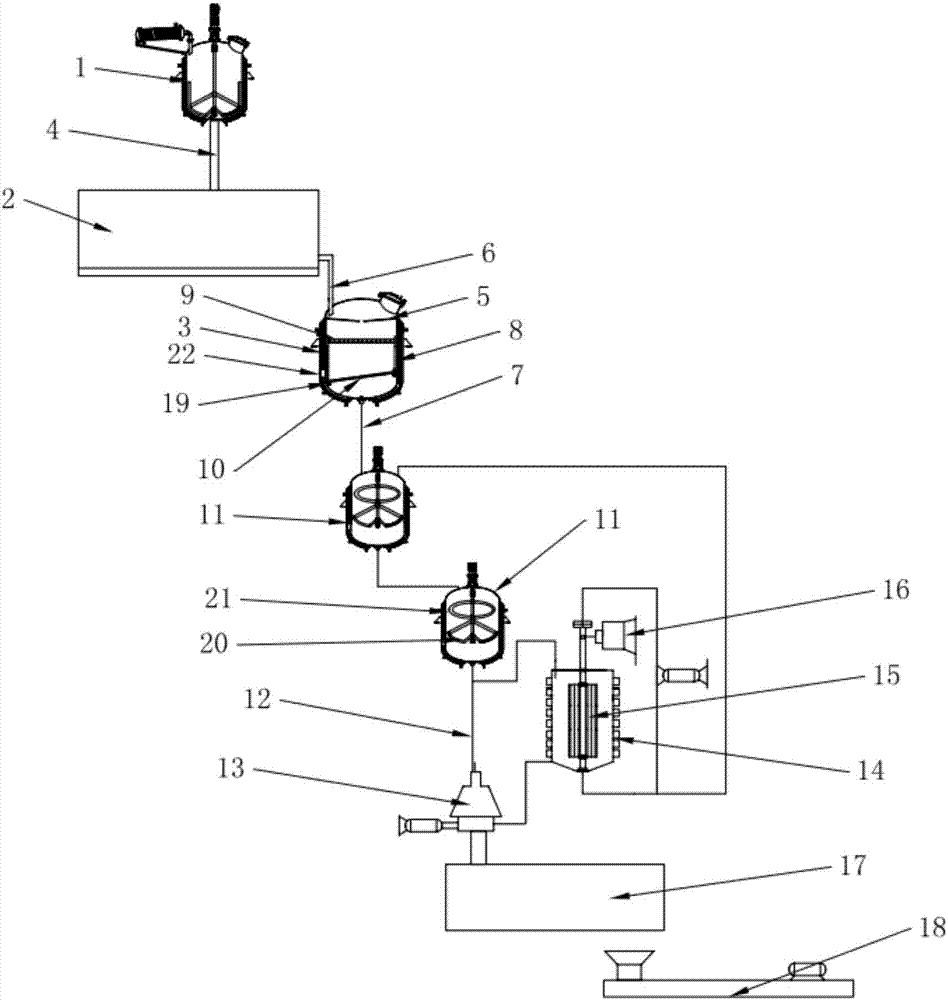

[0027] Such as figure 1 Shown, a kind of preparation equipment of sodium sulfate, including filter mechanism, crystallization mechanism, drying mechanism and conveying mechanism; Utilize the first delivery pipe 4 to communicate with the sediment clarification tank 2, filter tank 3 comprises tank body, the bottom of the tank body is provided with the first delivery pipe 6, is provided with the second delivery pipe 7 on the side wall of the tank body, the tank body An installation platform 8 is arranged around the inner wall, and a sieve body is installed on the installation platform 8;

[0028] The crystallization mechanism includes a continu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com