Organic sewage treatment method for high-concentration culture farm

A technology of organic sewage and treatment method, applied in biological water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of inconvenient operation and management, high operating cost and high investment in sewage treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following is a further detailed description of the high-concentration farm organic sewage treatment method of the present invention through specific examples.

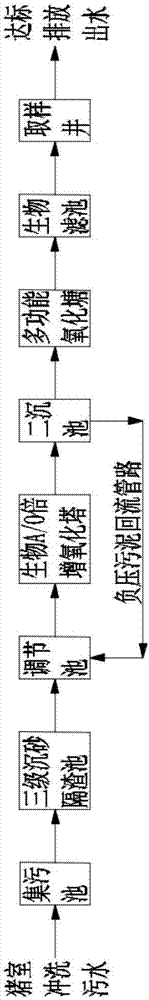

[0027] This embodiment provides a method for treating organic sewage in high-concentration farms. The schematic diagram of the process flow of the treatment method is as follows: figure 1 shown, including the following steps:

[0028] 1. The waste water from washing the pig room every day is sent to the sewage collection tank through the sewage pipe. The sewage collection tank is equipped with a mechanical grille to remove the solid matter in the waste water through the mechanical grille, thereby reducing the processing load of the subsequent process;

[0029] 2. The waste water from which solid matter has been removed is sent to the three-stage sand settling and slag separation tank to remove the fine particles in the waste water, and then uniformly enters the regulating tank;

[0030] 3. The black film fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com