Long-acting retarder and preparation method thereof

A retarder and long-acting technology, which is applied in the field of long-acting retarder and its preparation, can solve the problems that concrete is difficult to surface or even set in a tank, the effect of retarder is not ideal, and the initial setting time of concrete is advanced, etc., to achieve good Retarding effect, excellent retarding effect, little effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

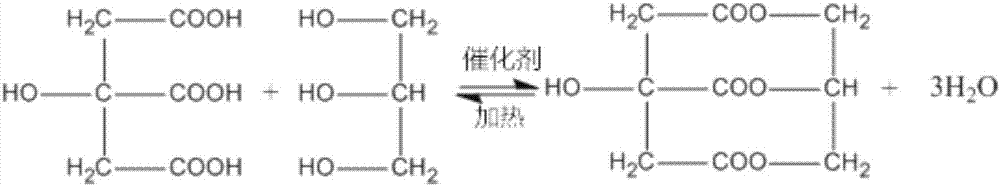

Method used

Image

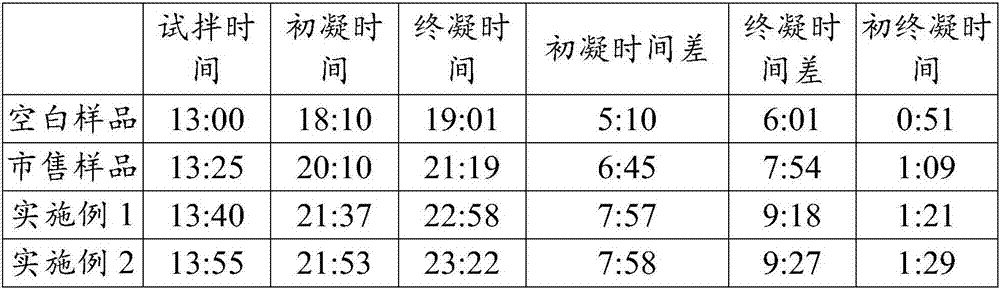

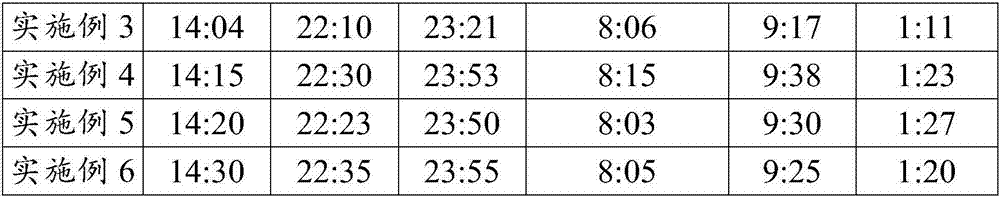

Examples

preparation example Construction

[0039] The embodiment of the present invention also provides a kind of preparation method of long-acting retarder, comprising:

[0040] The hydroxycarboxylic acid retarder and part of the polyol retarder are mixed to obtain a first mixed liquid; the esterification catalyst, the polymerization inhibitor and the remaining polyalcohol retarder are mixed to obtain a second mixed liquid.

[0041] Mixing the hydroxycarboxylic acid retarder and some polyol retarders in advance can prevent the local reaction concentration from being too high due to uneven distribution of raw materials after the start of the esterification reaction, which will reduce the efficiency of the esterification reaction and increase the by-products. At the same time, in the embodiment of the present invention, the esterification catalyst, the polymerization inhibitor and the remaining polyol retarder are mixed, and the polyol retarder can act as a dispersant, so that the esterification catalyst and the polymeri...

Embodiment 1

[0049] A kind of long-acting retarder, its preparation method is as follows:

[0050] S1. Put 50kg of glycerol at the bottom of the kettle, add 250kg of citric acid three times during the process of heating to 170°C, add one portion of citric acid each time until fully dissolved, and start stirring.

[0051] S2. Add 10 kg of prepared and weighed p-toluenesulfonic acid and 0.01 kg of hydroxyanisole into 120 kg of glycerol, and fully stir.

[0052] S3. Add the mixed S2 to S1 at a constant speed, then raise the temperature to 195° C., and stir at constant temperature for 8 hours.

[0053] S4. After S3 is completed, add 300 kg of sodium tripolyphosphate and 1 kg of low-viscosity cellulose ether, and continue stirring for 1 hour.

[0054] S5. Add dilution water to S4 to reach a concentration of 50% of the solution, so as to facilitate pipeline transportation, storage and application.

Embodiment 2

[0056] A kind of long-acting retarder, its preparation method is as follows:

[0057] S1. Put 200kg of glycerol at the bottom of the kettle, add 550kg of citric acid three times during heating to 170°C, add a portion of tartaric acid each time until fully dissolved, and start stirring.

[0058] S2. Add 40 kg of prepared and weighed p-concentrated sulfuric acid and 0.3 kg of hydroquinone into 260 kg of glycerol, and stir thoroughly.

[0059] S3. Add the mixed S2 to S1 at a constant speed, then raise the temperature to 195° C., and stir at constant temperature for 8 hours.

[0060] S4. After S3 is completed, 100 kg of sodium tripolyphosphate and 1 kg of methyl cellulose are added, and stirring is continued for 1 hour.

[0061] S5. Add dilution water to S4 to reach a concentration of 50% of the solution, so as to facilitate pipeline transportation, storage and application.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com