A kind of molding method of fiber-reinforced SIC-based composite material

A composite material and fiber-reinforced technology, which is applied in the field of preparation of ceramic matrix composite materials, can solve the problems of imperfect material forming, poor shaping of composite materials, and heavy processing workload, so as to shorten the preparation period, reduce processing allowance, and save energy. The effect of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

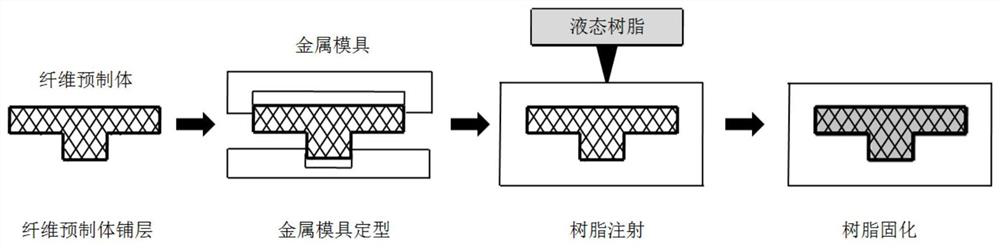

Method used

Image

Examples

Embodiment 1

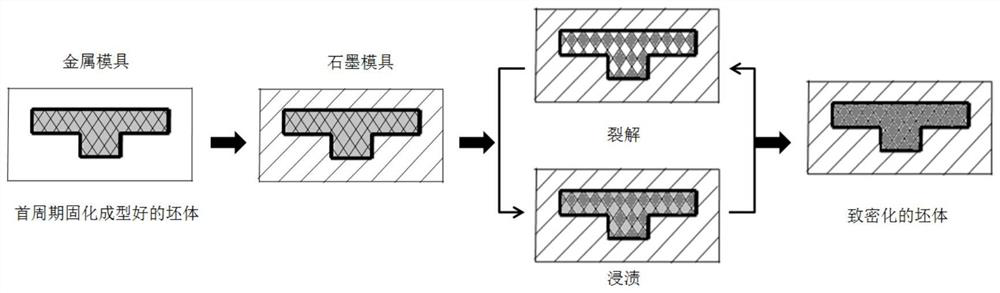

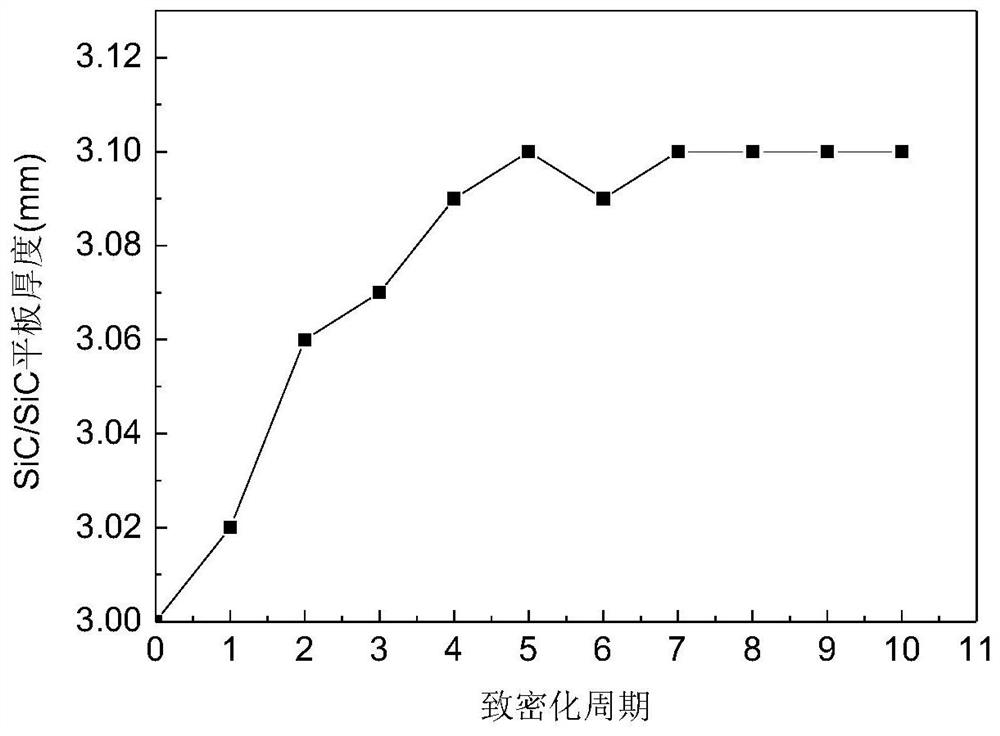

[0044] In this embodiment, the 1k SiC fiber is used as a raw material, a solventless liquid polycarcilane is a prior to apertured graphite cracking mold as a mold molding mold for fiber pre-enrichment preform, and a metal injection mold is formed as a first cycle molding mold. Finally, a precise SiC fiber reinforced SiC group composite plate (hereinafter referred to as: SiC / SiC tablet), the plate length is 100mm, width 100mm, thick 3mm, including the following steps:

[0045] The 1k SiC fiber was used as a raw material, and the SiC fiber prefabricate was prepared in a two-dimensional woven layer, and the fiber volume fraction was 45%.

[0046] Processing SiC / SiC flat prefabrication prefamped and densified cycle molding with holes of graphite cracking mold, in the graphite cleavage mold, aperture having a hole diameter of 2 mm, a hole pitch is 6 mm, a hole is evenly distributed, and the graphite is high in graphite.

[0047] The SiC fiber prefabricate after the laying is placed...

Embodiment 2

[0062] In this embodiment, the T300C fiber is used as a raw material, and the solvent-free liquid polycaroxane is a prior to aperture, and a molded graphite cleavage mold is used as a fifthal graphite cracking mold as a fiber pre-made graphite molding mold. As the first cycle molded mold, the metal injection mold is finally obtained, the precise molded C fiber reinforced SiC-based composite plate (hereinafter referred to as C / SiC flat), the plate length is 200mm, width of 200 mm, thick 4mm, including the following steps:

[0063] The T300C fiber is a raw material, and the C fiber prefabricate is prepared by two-dimensional woven layers, and the fiber size fraction is 40%.

[0064] Processing C / SiC flat fiber pre-formed graphite mold, processed C / SiC plate to cause crystallization cycle molded graphite cracking mold, in the graphite cracking mold, hole, aperture is 4mm, hole pitch is 8mm, hole pores Distribution, graphite material is high in graphite.

[0065] The laying C fibe...

Embodiment 3

[0080] In this embodiment, the 1k SiC fiber is used as a raw material, a solventless liquid polycarcilane is a prior to apertured graphite cracking mold as a mold molding mold for fiber pre-enrichment preform, and a metal injection mold is formed as a first cycle molding mold. Finally, a precise SiC fiber reinforced SiC matrix composite curved article is 280mm, 120mm wide, and 5mm wide, including the following steps:

[0081] The 1k SiC fiber was used as a raw material, and the SiC fiber prefabricate was prepared by 2.5d weaving, with a fiber volume fraction of 50%.

[0082] Processed SiC / SiC Curved Parts Pre-forming and Determination Periodic Filled Cracking Molds, and in the graphite cracking mold, the hole is 5 mm, the pore distance is 6mm, the holes are evenly distributed, the graphite is high in graphite .

[0083] The layered SiC curved article fiber prefabricate is placed in a hole in graphite cracking mold, and the holes of graphite cracking mold is fixed.

[0084] The S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com