Environment-friendly high-performance quickly de-molding polyurethane reaction injection molding compound and preparation method of self-catalyzed chain extender thereof

An injection molding, high-performance technology, applied in the direction of organic chemistry, etc., can solve the problem of material odor level and VOC being difficult to meet the requirements of environmental protection performance in the application field, and the proportion is large, so as to shorten the gel and demoulding time, and reduce the total amount. The amount of use, the effect of good self-acceleration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

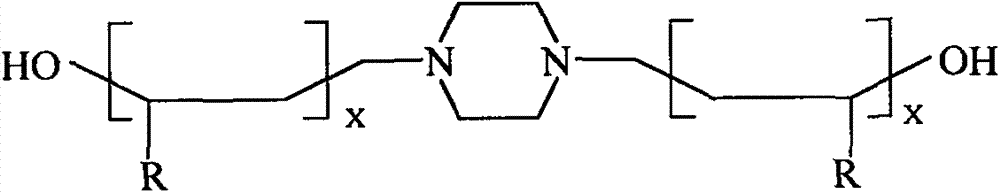

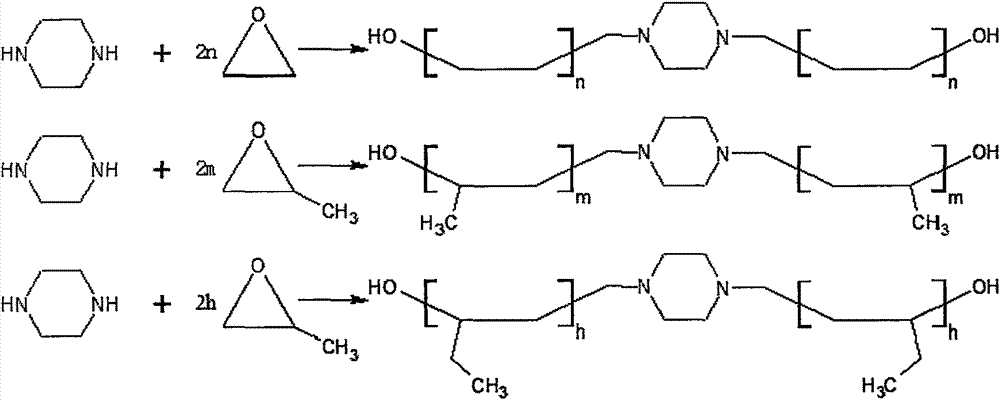

[0039] (1) Synthesis of self-catalyzed chain extender: Anhydrous piperazine is heated to 65°C in a reaction vessel with a condensation reflux device, and propylene oxide is prepared according to piperazine: propylene oxide=1: The molar ratio of 4 is added dropwise into the reaction vessel, after the dropwise addition, the temperature is raised to 80-85°C for another 4 hours, and the material is discharged after cooling to room temperature. The product structure obtained by the reaction is:

[0040]

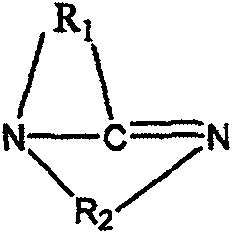

[0041] (2) Preparation of the composite catalyst: 10 parts of bismuth isooctanoate, 1 part of potassium isooctanoate, 15 parts of bicyclic amidine compounds, and 10 parts of glycerin, which are fully stirred and mixed uniformly before use.

[0042] (3) Preparation of the composition

[0043] 330N: Ethylene oxide-propylene oxide copolyether triol, hydroxyl value 33.5~36.5mgKOH / g

[0044] Component A: 330N, 77.5 parts, 8 parts of self-catalyzed chain extender prepared above, 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com