Lead storage battery grid with composite coating and preparation method of lead storage battery grid

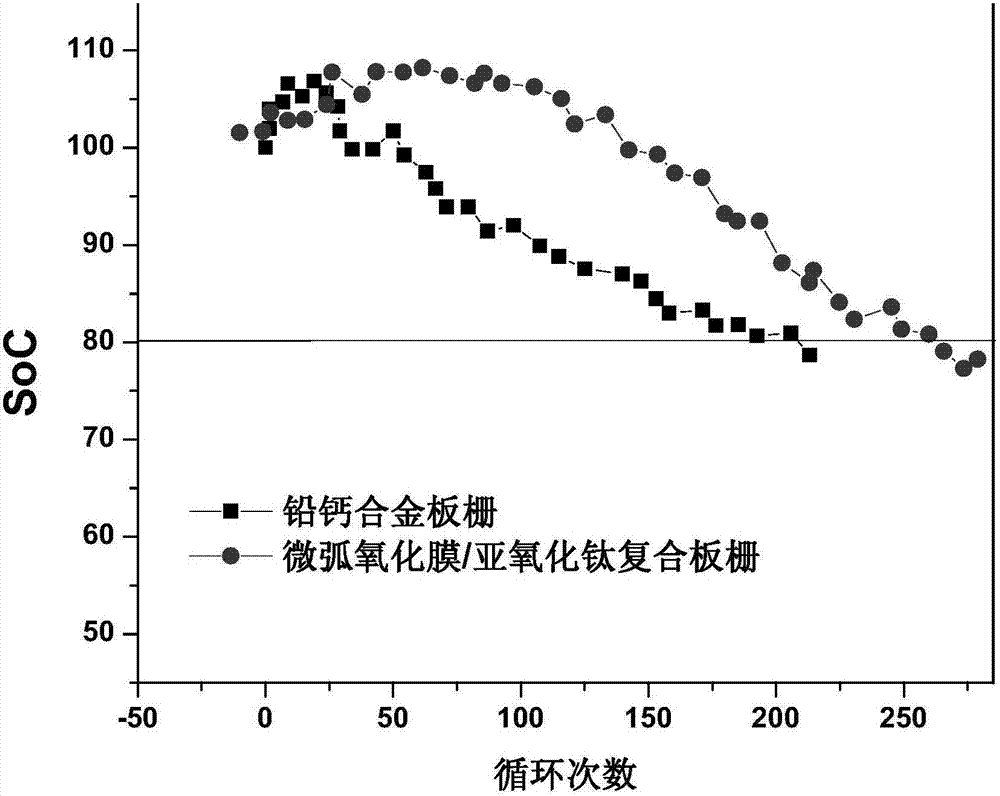

A lead-acid battery and composite coating technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve problems such as corrosion resistance, and achieve the effects of prolonging service life, enhancing protection performance, and ensuring contact conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

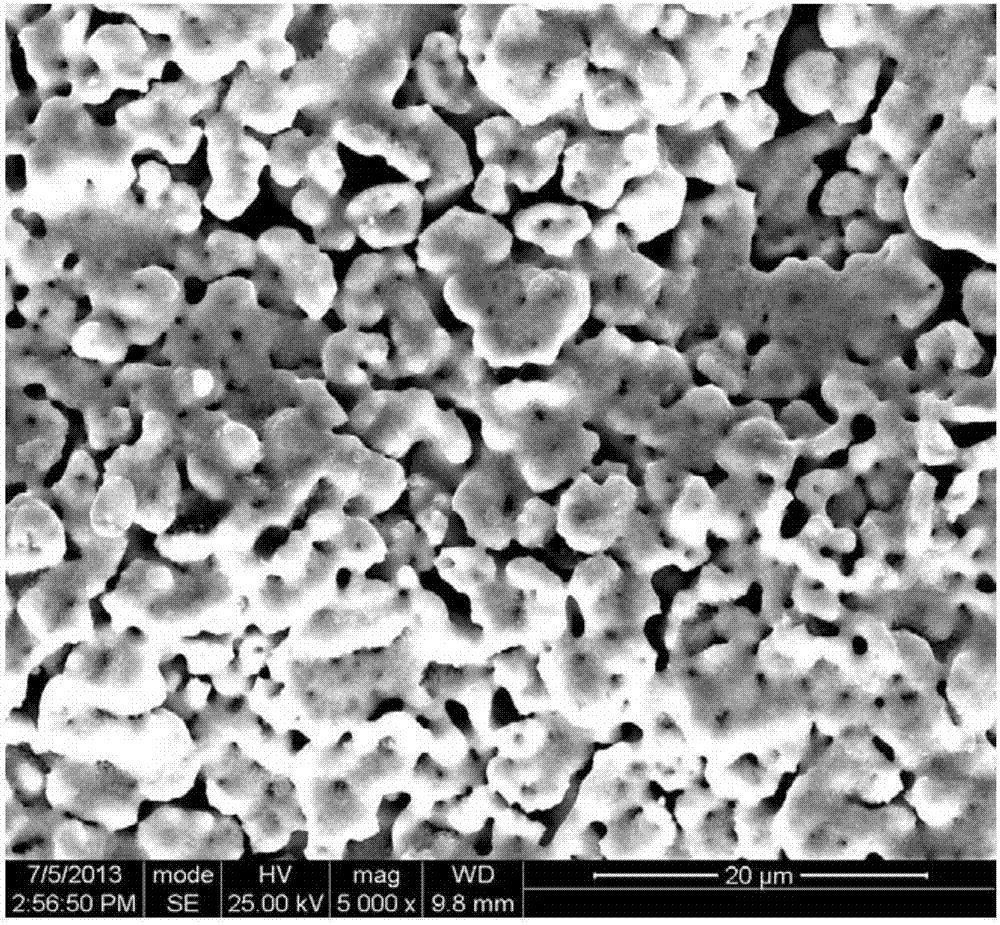

Image

Examples

Embodiment 1

[0036] (1) Electrochemical pretreatment: use the grid as the anode, and the stainless steel sheet as the cathode, immerse in a mixed solution of 0.1mol / L sodium hydroxide and 0.05mol / L sodium phosphate, use constant current mode, and the current density is 3.5Adm -2 , the processing time is 120s.

[0037] (2) Preparation of lead dioxide layer by electrochemical oxidation method: the pretreated lead alloy grid is used as the anode, and the lead plate is used as the cathode. In a sulfuric acid solution with a concentration of 1.65mol / L, the composite frequency conversion carrier control technology is used for electrochemical oxidation. Oxidation, the control parameters are: the positive oxidation termination voltage is 70V, the negative termination voltage is 35V, the oxidation time is 1.5h, and the current density is 30A / dm 2 , the frequency is 300Hz, and the positive and negative duty cycles are 20% and 20%.

[0038] The thickness of the lead dioxide layer was 10 μm.

[0039...

Embodiment 2

[0047] (1) Electrochemical pretreatment: use the grid as the anode, and the stainless steel sheet as the cathode, immerse in the mixed solution of 0.1mol / L sodium hydroxide and 0.05mol / L sodium phosphate, adopt constant current mode, and the current density is 4.8Adm -2 , the processing time is 210s.

[0048] (2) Preparation of lead dioxide layer by electrochemical oxidation method: the pretreated lead alloy grid is used as the anode, and the lead plate is used as the cathode. In a sulfuric acid solution with a concentration of 1.74mol / L, the composite frequency conversion carrier control technology is used for electrochemical oxidation. Oxidation, the control parameters are: the positive oxidation termination voltage is 95V, the negative termination voltage is 50V, the oxidation time is 2h, and the current density is 35A / dm 2 , the frequency is 450Hz, the positive and negative duty ratios are 30% and 20%, and the thickness of the obtained lead dioxide layer is 15 μm.

[0049...

Embodiment 3

[0054] (1) Electrochemical pretreatment: use the grid as the anode, and the stainless steel sheet as the cathode, immerse in a mixed solution of 0.1mol / L sodium hydroxide and 0.05mol / L sodium phosphate, use constant current mode, and the current density is 5.5Adm -2 , the processing time is 260s.

[0055] (2) Preparation of lead dioxide layer by electrochemical oxidation method: the pretreated lead alloy grid is used as the anode, and the lead plate is used as the cathode. In a sulfuric acid solution with a concentration of 1.95mol / L, the composite frequency conversion carrier control technology is used for electrochemical oxidation. Oxidation, the control parameters are: positive oxidation termination voltage is 110V, negative termination voltage is 75V, oxidation time is 3h, current density is 40A / dm 2 , the frequency is 600Hz, and the positive and negative duty cycles are 40% and 20%.

[0056] The thickness of the lead dioxide layer was 17 μm.

[0057] (3) Cathodic deposi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com