Preparation method and application of nickel cobaltate / hierarchical pore carbon electrode material

A technology of multi-level pores and nickel cobalt oxide, which is applied in the manufacture of hybrid/electric double-layer capacitors, hybrid capacitor electrodes, chemical instruments and methods, etc., can solve the problems of poor cycle stability and achieve easy operation, convenient and quick preparation methods, Effects suitable for promotional use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

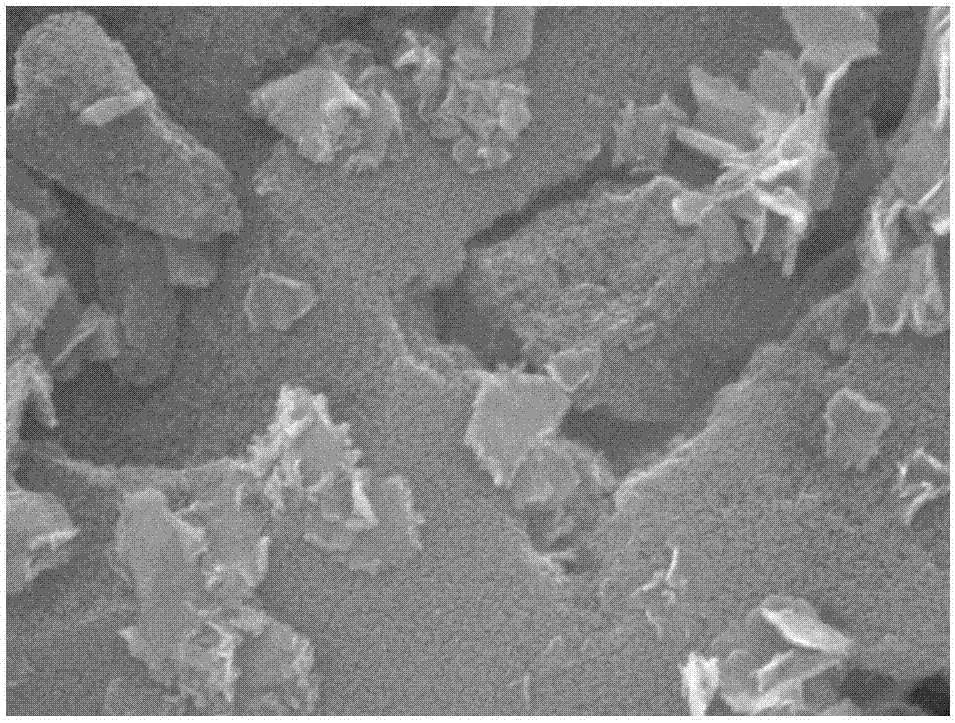

[0029] First, a certain amount of EDTA-3K was weighed into a 30mL nickel crucible and then placed in a tube furnace for calcination under the protection of a nitrogen atmosphere. It was raised from room temperature to 700 °C and maintained for 1.0 h, and the heating rate was controlled at 3.0 °C min -1 . After natural cooling, the black product was taken out, placed in an excess of dilute hydrochloric acid (5wt%) solution, magnetically stirred for 2 hours to remove impurities, and then washed with a large amount of deionized water to about pH=7.0, and dried at 60°C to obtain EDTA-3K based porous carbon materials.

[0030] Weigh 0.2g EDTA-3K-based porous carbon material and disperse it in 30mL deionized water, sonicate for 30min, while 1.0mmol CoCl 2 ·6H 2 O and 30 mmol of urea were dissolved in 35 mL of deionized water, stirred vigorously for 20 min, then added to the EDTA-3K-based porous carbon dispersion, and stirred gently at room temperature for 15 min to fully contact t...

Embodiment 2

[0034] First, a certain amount of EDTA-3K was weighed into a 30mL nickel crucible, placed in a tube furnace, and calcined under the protection of a nitrogen atmosphere. It was raised from room temperature to 800 °C and maintained for 1.0 h, and the heating rate was controlled at 7.0 °C min -1 . After natural cooling, the black product was taken out, placed in an excess of dilute hydrochloric acid (15wt%) solution, magnetically stirred for 2 hours to remove impurities, and then washed with a large amount of deionized water to about pH=7.0, and dried at 60°C to obtain EDTA-3K based porous carbon materials.

[0035] Weigh 0.2g EDTA-3K-based porous carbon material and disperse it in 30mL deionized water, sonicate for 30min, while 1.0mmol CoCl 2 ·6H 2 O and 30 mmol of urea were dissolved in 35 mL of deionized water, stirred vigorously for 20 min, then added the EDTA-3K-based porous carbon dispersion, and stirred gently at room temperature for 15 min to fully contact the two. The...

Embodiment 3

[0037] First, a certain amount of EDTA-3K was weighed into a 30mL nickel crucible, placed in a tube furnace, and calcined under the protection of a nitrogen atmosphere. It was raised from room temperature to 800 °C and maintained for 1.0 h, and the heating rate was controlled at 7.0 °C min -1 . After natural cooling, the black product was taken out, placed in an excess of dilute hydrochloric acid (15wt%) solution, magnetically stirred for 2 hours to remove impurities, and then washed with a large amount of deionized water to about pH=7.0, and dried at 60°C to obtain EDTA-3K based porous carbon materials.

[0038] Weigh 0.2g EDTA-3K-based porous carbon material and disperse it in 30mL deionized water, sonicate for 30min, and at the same time dissolve 1.0mmol NiCl 2 ·6H 2O and 30 mmol of urea were dissolved in 35 mL of deionized water, stirred vigorously for 20 min, then added to the EDTA-3K-based porous carbon dispersion, and stirred gently at room temperature for 15 min to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com