GaN based laser device and preparation method thereof

A technology of lasers and confinement layers, which is applied to lasers, laser components, semiconductor lasers, etc., can solve problems affecting optical power and slope efficiency, affecting optical confinement, and effective barriers of electronic blocking layers, so as to reduce optical loss and effectively Potential barrier enhancement, effect of increasing optical power and slope efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

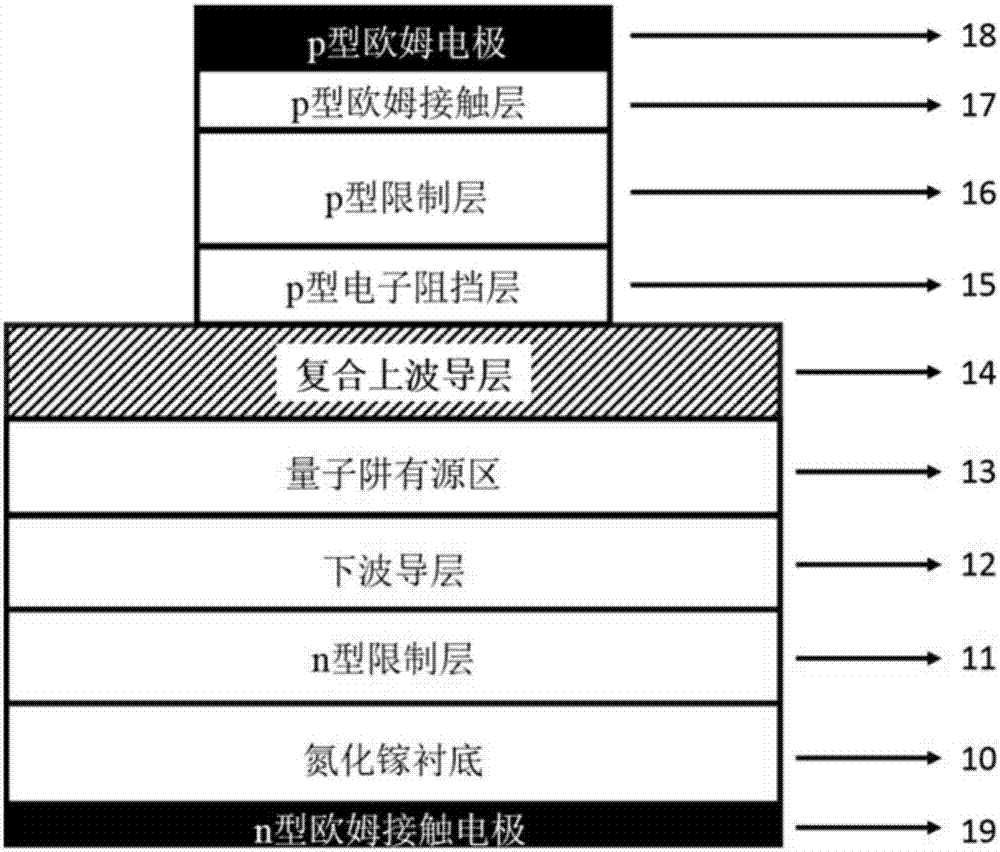

[0028] In an exemplary embodiment of the present invention, a method for manufacturing a GaN-based violet laser is provided. figure 1 It is a schematic structural diagram of a GaN-based violet laser according to an embodiment of the present invention. Such as figure 1 Shown, the preparation method of GaN-based violet laser of the present invention comprises the following steps:

[0029] S1: On the gallium nitride substrate 10, the n-type confinement layer 11, the lower waveguide layer 12, the quantum well active region 13, the composite upper waveguide layer 14, the p-type electron blocking layer 15, p-type confinement layer 16, p-type ohmic contact layer 17;

[0030] S2: Dry etching the p-type ohmic contact layer 17, the p-type confinement layer 16, the p-type electron blocking layer 15 and the composite upper waveguide layer 14 into a laser ridge shape;

[0031] S3: growing an oxide film on the formed ridge, and fabricating a p-type ohmic electrode 18 by photolithography;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com