Red light semiconductor laser with high reliability

A reliability and laser technology, applied to the structure of the active region, can solve the problems of low characteristic temperature and life, high light absorption and high junction temperature, and achieve reduced Joule heat generation, good confinement, and reduced series resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

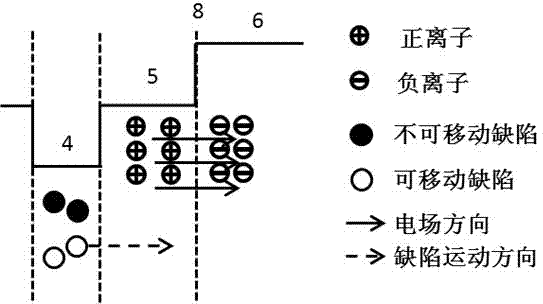

Problems solved by technology

Method used

Image

Examples

Embodiment 1

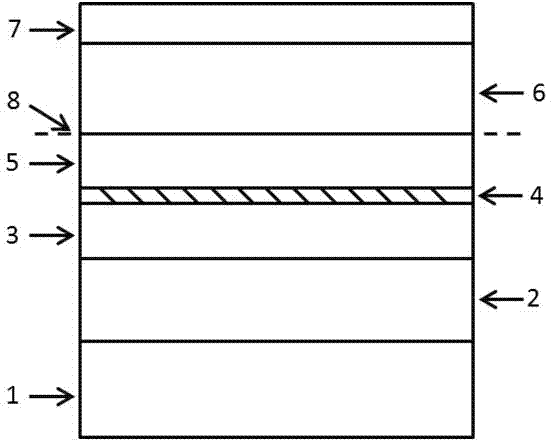

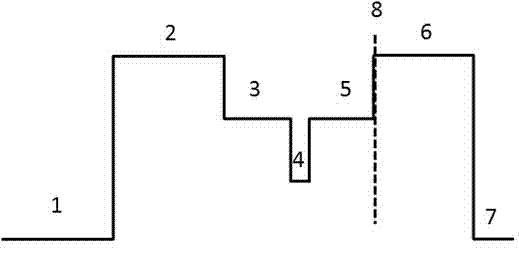

[0043] Substrate 1 is a Si-doped GaAs(100) single crystal substrate with a 15° orientation to , and the doping concentration is 3×10 18 cm -3 .

[0044] The lower confinement layer 2 is Si-doped (Al 0.7 Ga 0.3 ) 0.5 In 0.5 P, the doping concentration is 1×10 18 cm -3 .

[0045] The lower waveguide layer 3 is weakly N-type Si-doped (Al 0.5 Ga 0.5 ) 0.5 In 0.5 P, the doping concentration is 6×10 16 cm -3 .

[0046] Quantum well active region 4 is Ga with a thickness of 15nm 0.5 In 0.5 p.

[0047] The upper waveguide layer 5 is weakly N-type Si-doped (Al 0.5 Ga 0.5 ) 0.5 In 0.5 P, the doping concentration is 6×10 16 cm -3 .

[0048] The upper confinement layer 6 is Mg-doped (Al 0.7 Ga 0.3 ) 0.5 In 0.5 P, the doping concentration is 2×10 18 cm -3 .

[0049] The ohmic contact layer 7 is GaAs with a thickness of 200nm, and the doping concentration of Zn is 3×10 19 cm -3 .

[0050] In this embodiment the confinement layer is (Al 0.7 Ga 0.3 ) 0.5 In...

Embodiment 2

[0052] The difference between this embodiment and the highly reliable red semiconductor laser described in Embodiment 1 is:

[0053] The lower confinement layer 2 is Se-doped Al with a thickness of 1.0 μm 0.5 In 0.5 P, the doping concentration is 1×10 18 cm -3 .

[0054] The lower waveguide layer 3 is weakly N-type Se-doped (Al 0.5 Ga 0.5 ) 0.5 In 0.5 P, the doping concentration is 8×10 16 cm -3 .

[0055] The quantum well 4 is Ga with a thickness of 10nm 0.6 In 0.4 p.

[0056] The upper waveguide layer 5 is weakly N-type Se-doped (Al 0.5 Ga 0.5 ) 0.5 In 0.5 P, the doping concentration is 8×10 16 cm -3 .

[0057] The upper confinement layer 6 is Mg-doped Al with a thickness of 1.0 μm 0.5 In 0.5 P, the doping concentration is 2×10 18 cm -3 .

[0058] The ohmic contact layer 7 is GaAs with a thickness of 200nm, and the doping concentration of C is 5×10 19 cm -3 .

[0059] In this embodiment, the confinement layer uses Al with a smaller refractive index...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Doping concentration | aaaaa | aaaaa |

| Doping concentration | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com