Nanometer antifouling coating liquid, and preparation method and application thereof

An anti-fouling coating and nano-technology, applied in the coating and other directions, can solve the problems of poor machine cleaning effect, high cost, large water and electricity consumption, etc., and achieve the effects of excellent waterproof, reduced water consumption, and reduced operation and maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

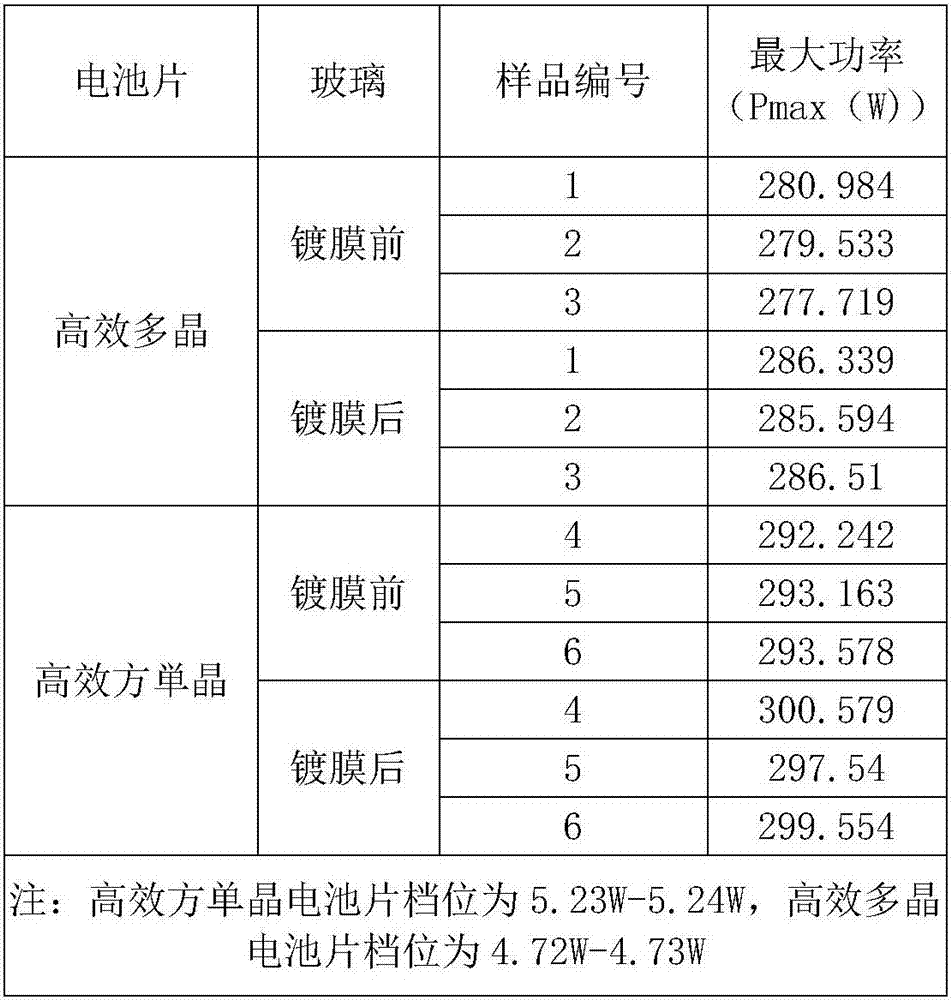

Examples

Embodiment 1

[0027] This embodiment provides a nano-antifouling coating solution and its preparation method. The nano-antifouling coating solution of this embodiment uses organic silicon compounds with low surface energy as raw materials, specifically, a certain ratio of ethyl orthosilicate Esters, organic modifiers, deionized water, organic solvents, catalysts. Wherein, the organic solvent is absolute ethanol, the catalyst is silazane, and the organic modifier is dimethyldiethoxysilane.

[0028] In the present embodiment, the preparation method of the nano antifouling coating liquid is as follows:

[0029] Step S0: Weighing raw materials

[0030] Specifically, using an electronic scale and a beaker, etc., weighed 100 parts of tetraethyl orthosilicate, 60 parts of deionized water, 15 parts of absolute ethanol, 12 parts of silazane and 15 parts of dimethyldimethoxy Ethoxysilane.

[0031] Step S1: Preparation of silica sol

[0032] Specifically, add 60 parts of deionized water, 15 parts ...

Embodiment 2

[0036] This embodiment provides a nano-antifouling coating solution and its preparation method. The nano-antifouling coating solution of this embodiment uses organic silicon compounds with low surface energy as raw materials, specifically, a certain ratio of ethyl orthosilicate Esters, organic modifiers, deionized water, organic solvents, catalysts. Wherein, the organic solvent is isopropanol, the catalyst is trimethylchlorosilane, and the organic modifier is octadecyltriethoxysilane.

[0037] In the present embodiment, the preparation method of the nano antifouling coating solution is as follows:

[0038] Step S0: Weighing raw materials

[0039] Specifically, using an electronic scale and a beaker, etc., weighed 100 parts of tetraethyl orthosilicate, 8 parts of deionized water, 0.5 parts of isopropanol, 1 part of trimethylchlorosilane and 2 parts of octadecadecane in terms of mass fractions. Alkyltriethoxysilanes.

[0040] Step S1: Preparation of silica sol

[0041] Specifi...

Embodiment 3

[0045] This embodiment provides a nano-antifouling coating solution and its preparation method. The nano-antifouling coating solution of this embodiment uses organic silicon compounds with low surface energy as raw materials, specifically, a certain ratio of ethyl orthosilicate Esters, organic modifiers, deionized water, organic solvents, catalysts. Wherein, the organic solvent is propanol, the catalyst is octamethylcyclotetrasiloxane, and the organic modifier is heptadecafluorodecyltriethoxysilane.

[0046] In the present embodiment, the preparation method of the nano antifouling coating solution is as follows:

[0047] Step S0: Weighing raw materials

[0048] Specifically, using an electronic scale and a beaker, weighed 100 parts of tetraethyl orthosilicate, 34 parts of deionized water, 7.5 parts of propanol, 6 parts of octamethylcyclotetrasiloxane and 10 parts of Heptadecafluorodecyltriethoxysilane.

[0049] Step S1: Preparation of silica sol

[0050] Specifically, add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com