A kind of preparation method of high-content omega-3 fatty acid ethyl ester

A fatty acid ethyl ester, high-content technology, applied in the preparation of carboxylate, oil/fat refining, and preparation of organic compounds, etc. The effect of short heating time, good quality and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

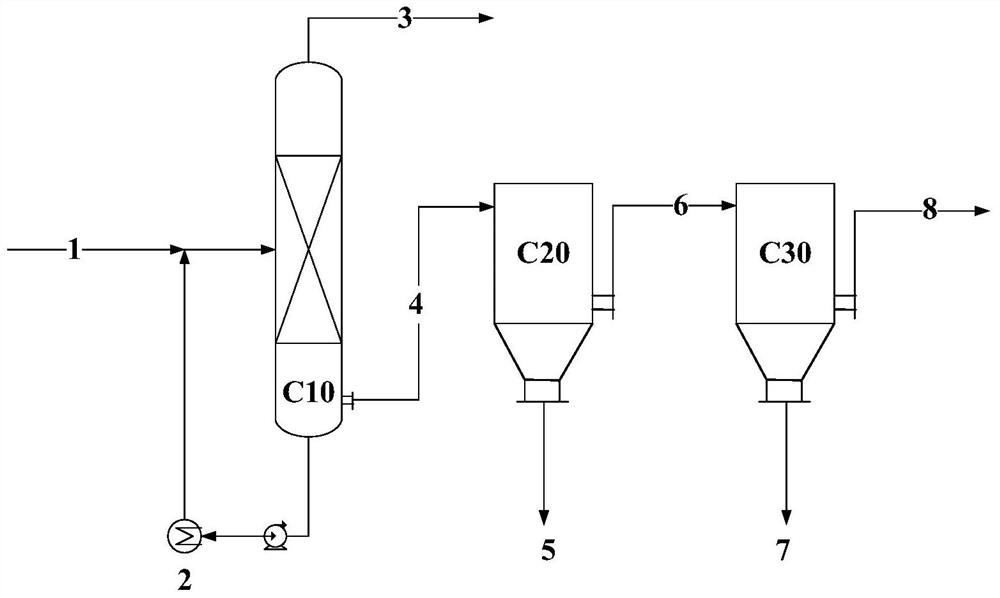

[0025]The combined rectification-molecular distillation system of the present invention is suitable for the separation and purification of heat-sensitive polyunsaturated fatty acids by integrating the respective advantages of rectification and molecular distillation. The working process of this rectification-molecular distillation combined system is as follows: the material flow 1 obtained after the alcoholysis and degassing of anchovy oil, the content of EPA ethyl ester in material 1 is 19.5%, and the content of DHA ethyl ester is 10.0%; Stage rectification column C10 is rectified and separated into light component 3 and heavy component 4. The bottom material is pumped and circulated, enters the bottom reboiler 2 for heating and then refluxes into the rectification column C10. The reboiler is a falling film type , the heating temperature is 180-200 DEG C [the temperature here is the heating temperature of the reboiler (equivalent to the temperature of the tower kettle), and th...

Embodiment 2

[0028] Material stream 1 obtained after alcoholysis and degassing of miscellaneous fish oil (mixed fish oil of anchovy oil and sardine oil), the content of EPA ethyl ester in material 1 is 17.6%, and the content of DHA ethyl ester is 12.8%; firstly, through the first stage of rectification Column C10 is rectified and separated into light component 3 and heavy component 4. The material at the bottom of the tower is pumped and circulated, enters the reboiler 2 at the bottom of the tower to be heated, and then refluxes into the rectification tower C10. The reboiler is a falling film type, and the heating temperature is The temperature at the top of the tower is 180°C, the vacuum at the top of the tower is 10-20Pa, and the temperature at the top of the tower is 140-180°C; the heavy component 4 is separated from the light component 5 and the heavy component 6 through the second-stage molecular evaporator C20, and the light component 5 is High content of EPA ethyl ester, the content ...

Embodiment 3

[0030] The material stream 1 obtained after alcohol hydrolysis and degassing of tuna oil, the content of EPA ethyl ester in material 1 is 6.6%, the content of DHA ethyl ester is 24.8%; firstly, it is separated into light component 3 by rectification of the first stage rectification column C10 And heavy component 4, the material at the bottom of the tower is pumped and circulated, enters the reboiler 2 at the bottom of the tower to be heated, and then refluxes into the rectification tower C10. -20Pa, the temperature at the top of the tower is 140-180°C; the heavy component 4 passes through the second-stage molecular evaporator C20 to separate the light component 5 and the heavy component 6, in which the light component 5 is high-content Omega-3 ethyl ester, which The content of EPA ethyl ester + DHA ethyl ester is 65.7%, and the ratio of EPA ethyl ester and DHA ethyl ester can be adjusted by heating temperature. When the heating temperature of C20 is 150-160°C, DHA ethyl ester:E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com