A kind of self-steering acidification liquid and its preparation method and application

An acidifying fluid and self-steering technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of large reservoir damage, low reservoir temperature, limitation, etc., so as to improve the temperature resistance performance and reverse drainage. Efficiency, the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

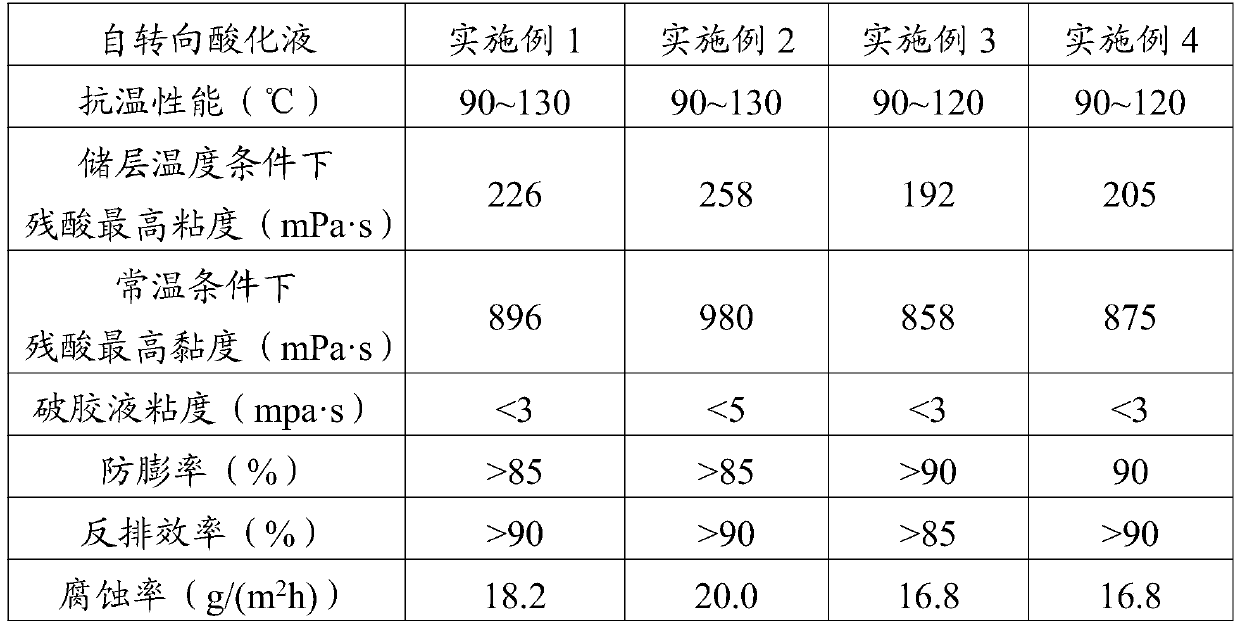

Examples

preparation example Construction

[0045] The present invention provides the preparation method of self-steering acidification liquid described in above-mentioned technical scheme, comprises the following steps:

[0046] The self-steering acidizing solution is obtained by mixing the derivatives of betaine erucate, betaine surfactants, stabilizers, anti-temperature agents, corrosion inhibitors, mutual solvents, drainage aids, acids and water.

[0047] When preparing the self-steering acidification liquid, the present invention has no special limitation on the order of adding components in the self-steering acidification liquid, and any order of addition can be adopted. In the present invention, there is no special limitation on the mixing, and a technical solution well known to those skilled in the art can be used to mix the components uniformly. In the present invention, the mixing is preferably carried out under stirring conditions, and the stirring rate is preferably 200-400 r / min, more preferably 250-350 r / m...

Embodiment 1

[0051] The component distribution ratio of the self-steering acidification solution: 5 wt% of 13-docosenoic acid amidopropyl xanthyl betaine, 0.8 wt% of octadecenoic acid amidopropyl betaine, and 15% hydrochloric acid by mass 20wt%, citric acid 1.5wt%, dipropanol 1wt%, polyacrylic acid 0.5wt%, ethylene glycol monobutyl ether 2wt%, perfluoropolyoxypropylene heptanol ether 0.25wt% and the rest water.

[0052] According to the above-mentioned component distribution ratio, under the condition of a stirring rate of 200r / min, the various components were mixed, and the stirring was continued for 40 minutes to obtain a self-steering acidification solution.

Embodiment 2

[0054] The component distribution ratio of the self-steering acidification solution: 13-docosenoic acid amidopropyl-dihydroxyethyl betaine 4wt%, octadecenoic acid amidopropyl-dihydroxyethyl betaine 1wt%, mass percent 20% hydrochloric acid 15wt%, 2,3,5,6-tetrahydroxy-2-hexenoic acid-4-lactone 1wt%, glycerol 0.5wt%, sodium polyphosphate 0.3wt%, diethylene glycol Alcohol ethyl ether 1wt%, perfluoropropionamido-1,2-ethylenemethyldiethylammonium iodide 0.5wt%, and the rest water.

[0055] According to the above-mentioned component distribution ratio, under the condition of a stirring rate of 400r / min, the components were mixed, and the stirring was continued for 20 minutes to obtain a self-steering acidification solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com