Complex heating type biological carbon production equipment and process with automatic temperature control

A technology of composite heating and production equipment, which is applied in the fields of biofuel, petroleum industry, special forms of dry distillation, etc. It is difficult to accurately control the temperature of carbonization and other problems, so as to avoid the difference in properties, shorten the cooling time, and reduce the transformation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] As introduced in the background technology, the existing biochar production process and equipment still have problems such as high production energy consumption, long production time, and inability to produce in batches. Based on this, the present invention provides an environmentally friendly biochar with automatic temperature control Biochar production process and equipment. The induced draft fan, temperature sensor, temperature display and electric heating device are all commercially available products.

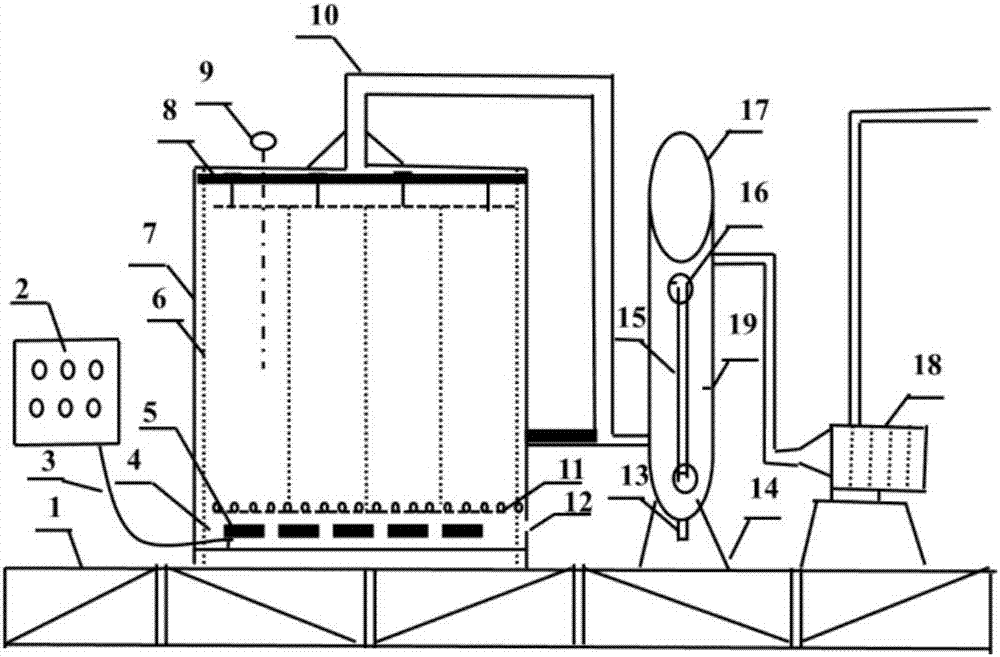

[0044] The invention provides an environment-friendly biochar production equipment with automatic temperature control, such as figure 1 and figure 2 As shown, it includes induced draft fan 18, motor, external heating device 5, dry carbonization system, flue gas purification system and cooling carbon discharge device; wherein external heating device 5 is an electric heating device;

[0045] The motor is arranged on one side of the induced draft fan 18 and is conne...

Embodiment 2

[0053] A kind of environment-friendly biochar production equipment with automatic temperature control, such as Figure 1 ~ Figure 3 As shown, it includes an induced draft fan 18, a motor, an electric heating device, a dry carbonization system, a flue gas purification system and a cooling and carbonization device;

[0054] The induced draft fan and electric heating device keep the temperature in the carbonization furnace constant during the carbonization process;

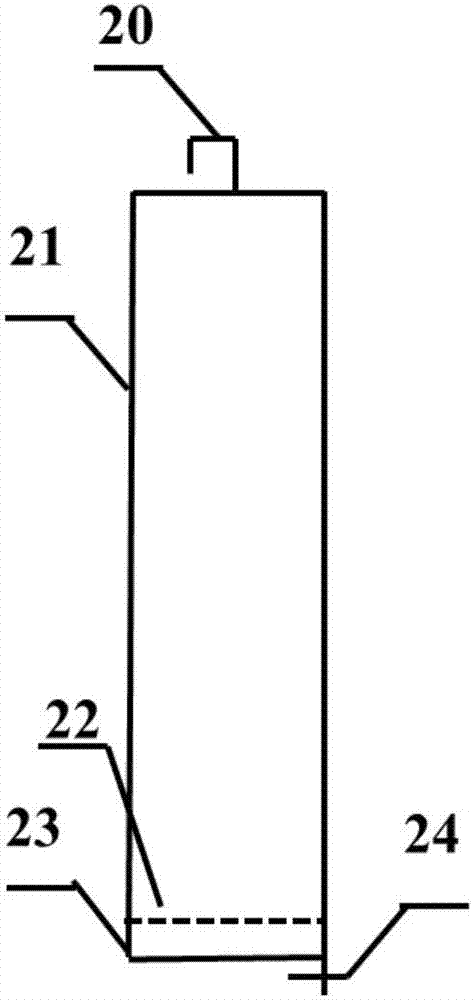

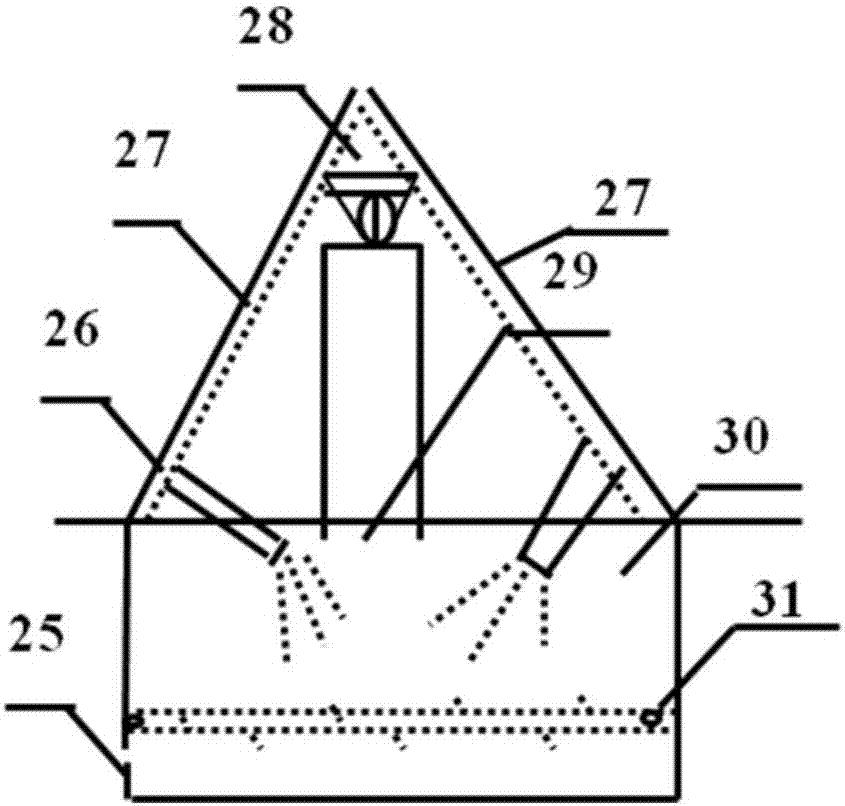

[0055] The dry carbonization system comprises a carbonization furnace 6, a combustion chamber 4, a pyrolysis chamber 21, an electric heating device, a temperature sensor and a flue gas discharge pipe 10; the carbonization furnace 6 is a horizontal structure, and the pyrolysis chamber 21, the combustion chamber 4, a temperature sensor and The electric heating device is arranged inside the carbonization furnace 6, and a suspension bracket 8 is arranged at the top inside the carbonization furnace 6, and the hanging hook...

Embodiment 3

[0063] The invention also provides a composite heating biochar production process with automatic temperature control. like Figure 4 As shown, the process mainly includes three steps:

[0064] Step 1: Put the extruded crop stalks into the pyrolysis chamber 21. The structure of the pyrolysis chamber 21 is that the upper part is completely sealed, and the lower part has a double-layer sealing cover that can be opened and closed. There are no holes in the outer airtight cover; close the lower inner layer perforated cover plate 22 of the pyrolysis chamber, and open the outer airtight cover plate 23. The pyrolysis chamber is fixed on the suspension bracket 8 in the carbonization furnace through the pyrolysis chamber hanging hook 20, and certain pores are left between the pyrolysis chambers 21 to facilitate smoke discharge and temperature balance.

[0065] Step 2: Close chamber 6 of the carbonization furnace, open the induced draft fan and the flue gas purification system, and set...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com