Dicing chip Bonding Film And Method For Manufacturing Semiconductor Device

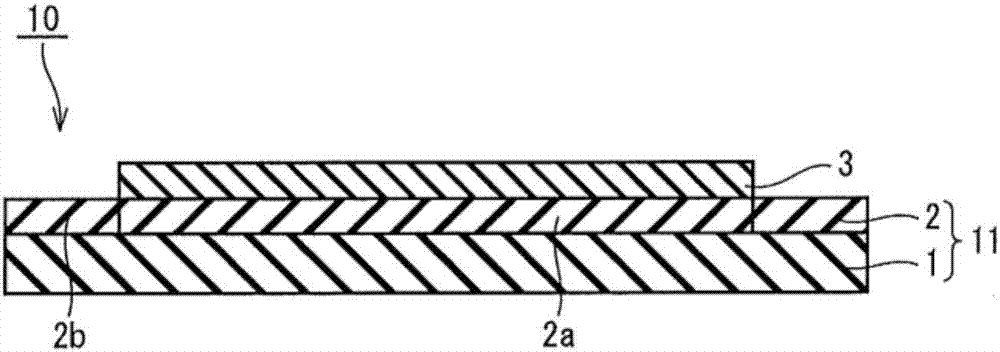

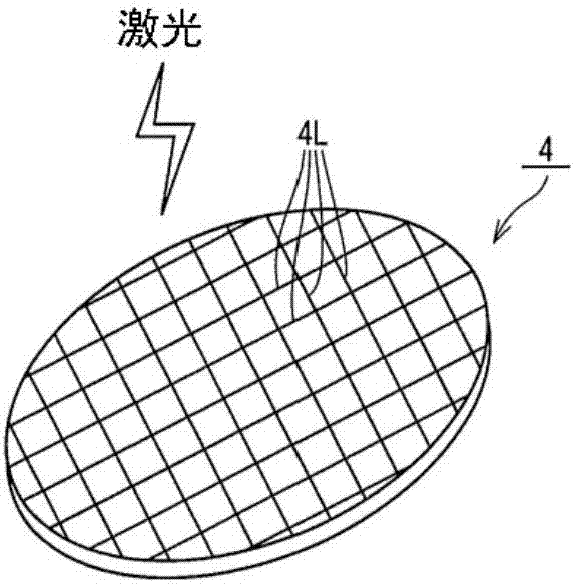

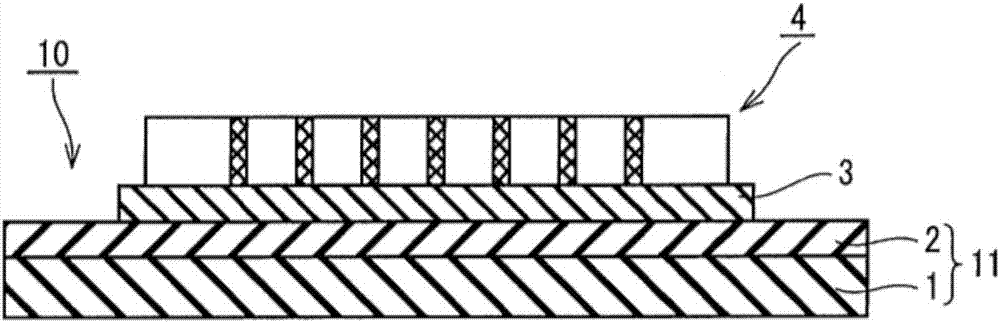

A technology for die-bonding films and dicing chips, which is used in semiconductor/solid-state device manufacturing, semiconductor devices, and thin-film/sheet-like adhesives, etc., and can solve problems such as inability to pick up properly and chips that cannot be peeled off from dicing sheets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0185]

[0186] 100 parts of 2-ethylhexyl acrylate (hereinafter also referred to as "2EHA"), 2-hydroxyethyl acrylate (hereinafter also referred to as 19 parts called "HEA"), 0.4 parts of benzoyl peroxide, and 80 parts of toluene were subjected to polymerization treatment at 60° C. for 10 hours in a nitrogen stream to obtain an acrylic polymer A.

[0187] Add 1.2 parts of 2-methacryloyloxyethyl isocyanate (hereinafter also referred to as "MOI") to this acrylic polymer A, and perform addition reaction treatment at 50°C for 60 hours in an air stream to obtain acrylic polymer A. Polymer A'.

[0188] Next, 1.3 parts of a polyisocyanate compound (trade name "CORONATEL", manufactured by Nippon Polyurethane Co., Ltd.) and a photopolymerization initiator (trade name "IRGACURE 184", manufactured by Ciba Specialty Chemicals Inc.) were added to 100 parts of the acrylic polymer A'. 3 parts) to prepare a binder solution (also referred to as "binder solution A").

[0189] The adhesive so...

Embodiment 2

[0200]

[0201] The following (a) to (e) were dissolved in methyl ethyl ketone to obtain an adhesive composition solution B having a solid content concentration of 20% by weight.

[0202] (a) Acrylic resin (trade name "SG-708-6" manufactured by Nagase ChemteX Corporation, glass transition temperature (Tg): 4°C): 100 parts

[0203] (b) Epoxy resin (trade name "JER1010", manufactured by Mitsubishi Chemical Corporation, solid at 23° C.): 140 parts

[0204] (c) Epoxy resin (trade name "JER828" manufactured by Mitsubishi Chemical Corporation, liquid at 23°C): 60 parts

[0205] (d) Phenolic resin (trade name "MEH-7851ss" manufactured by Meiwa Kasei Co., Ltd., solid at 23°C): 100 parts

[0206] (e) Spherical silica (trade name "SO-25R" manufactured by Admatechs Co., Ltd.): 40 parts

[0207] The adhesive composition solution B is coated on a release-treated film (release liner) formed of a polyethylene terephthalate film with a thickness of 50 μm that has been subjected to a silic...

Embodiment 3

[0211]

[0212] The following (a) to (e) were dissolved in methyl ethyl ketone to obtain an adhesive composition solution C having a solid content concentration of 20% by weight.

[0213] (a) Acrylic resin (trade name "SG-70L" manufactured by Nagase ChemteX Corporation, glass transition temperature (Tg): -13°C): 100 parts

[0214] (b) Epoxy resin (trade name "JER1010", manufactured by Mitsubishi Chemical Corporation, solid at 23° C.): 140 parts

[0215] (c) Epoxy resin (trade name "JER828" manufactured by Mitsubishi Chemical Corporation, liquid at 23°C): 60 parts

[0216] (d) 100 parts of phenolic resin (trade name "MEH-7851ss" manufactured by Meiwa Chemical Industry Co., Ltd., solid at 23° C.)

[0217] (e) Spherical silica (trade name "SO-25R" manufactured by Admatechs Co., Ltd.): 100 parts

[0218] The adhesive composition solution C is coated on a release-treated film (release liner) formed of a polyethylene terephthalate film with a thickness of 50 μm that has been sub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com