Near infrared emitting fluorescent carbon dot having up-conversion and down-conversion functions and preparation method thereof

A technology of fluorescent carbon dots and conversion functions, applied in the fields of chemistry and material science, can solve problems such as health hazards, cell lesions, and restricted applications, and achieve the effects of convenient operation, improved resolution, and large Stokes shift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

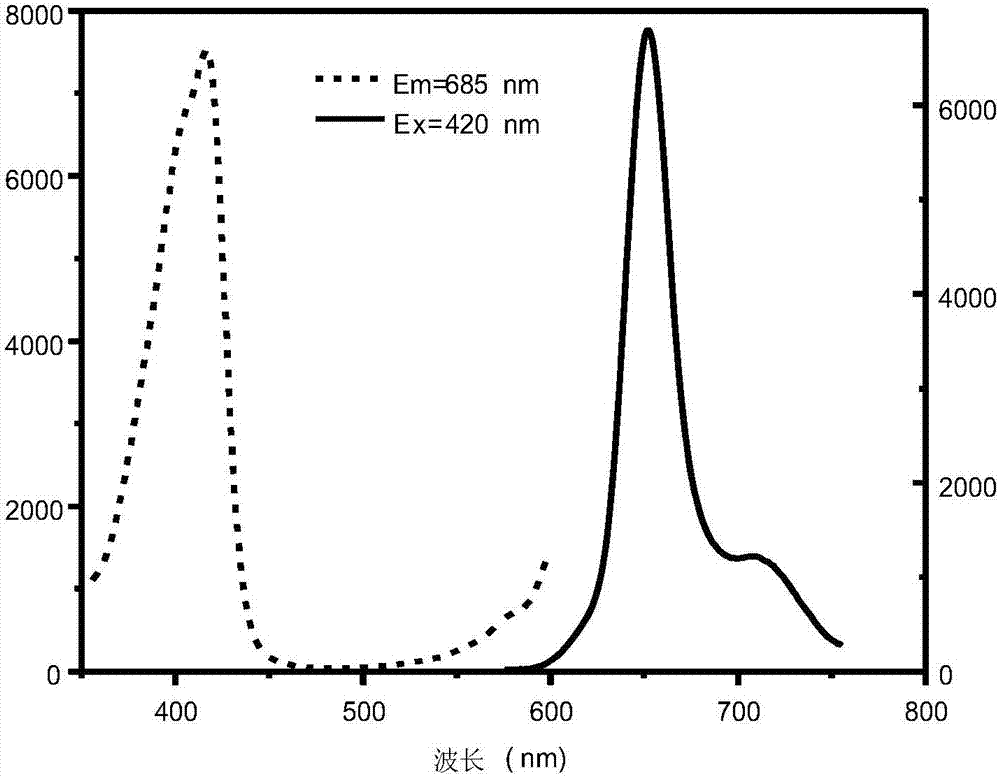

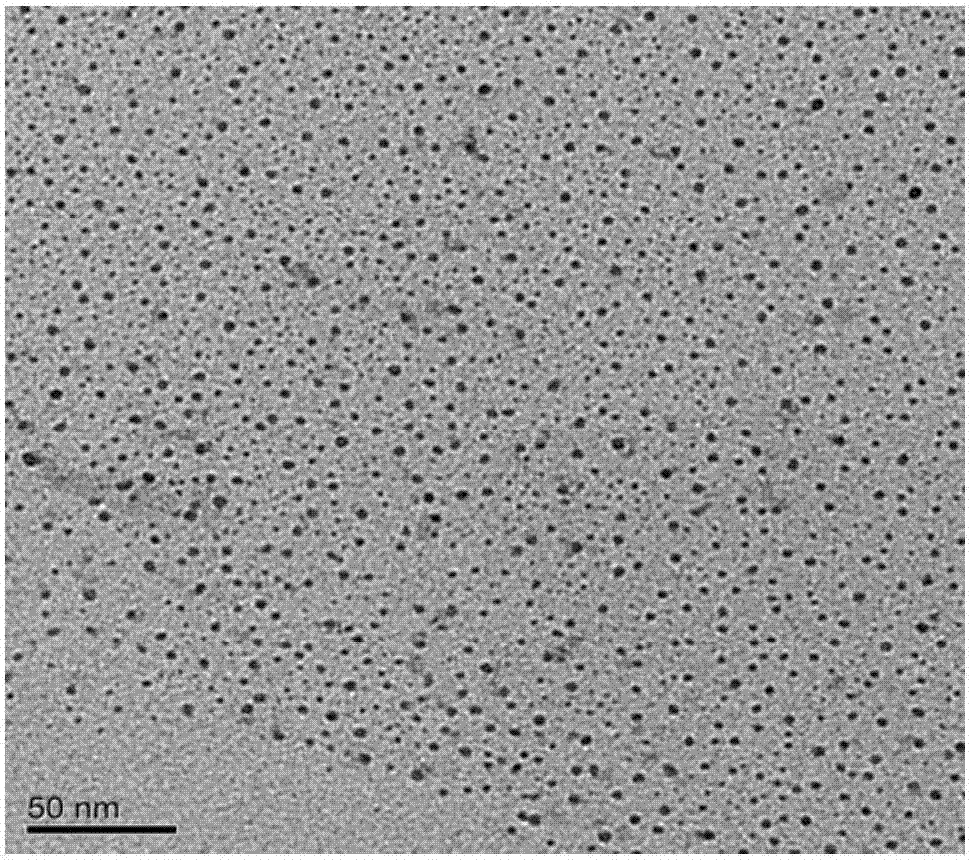

[0037] Example 1 Glutathione was dissolved in formamide to prepare a solution with a mass fraction of 1%. Take 50ml of the above solution and place it in a 100ml microwave reactor, then place the reactor in the microwave reactor, and take out the reactor after reacting at 160°C for 1 hour. After cooling to room temperature naturally, the reaction solution was diluted with water, dialyzed until there was no fluorescence in the dialysate, and the finally obtained solid, that is, the target product, was dried in a vacuum drying oven and sealed for storage. The elemental analysis test shows that the target product obtained in this example is carbon dots. Also, the fluorescence emission spectrum and excitation spectrum of the carbon dots obtained in this embodiment are as follows figure 1 As shown, the half width of the fluorescence emission peak is narrow, only 30nm, the fluorescence emission peak basically does not change with the excitation light wavelength, and has a large Sto...

Embodiment 2

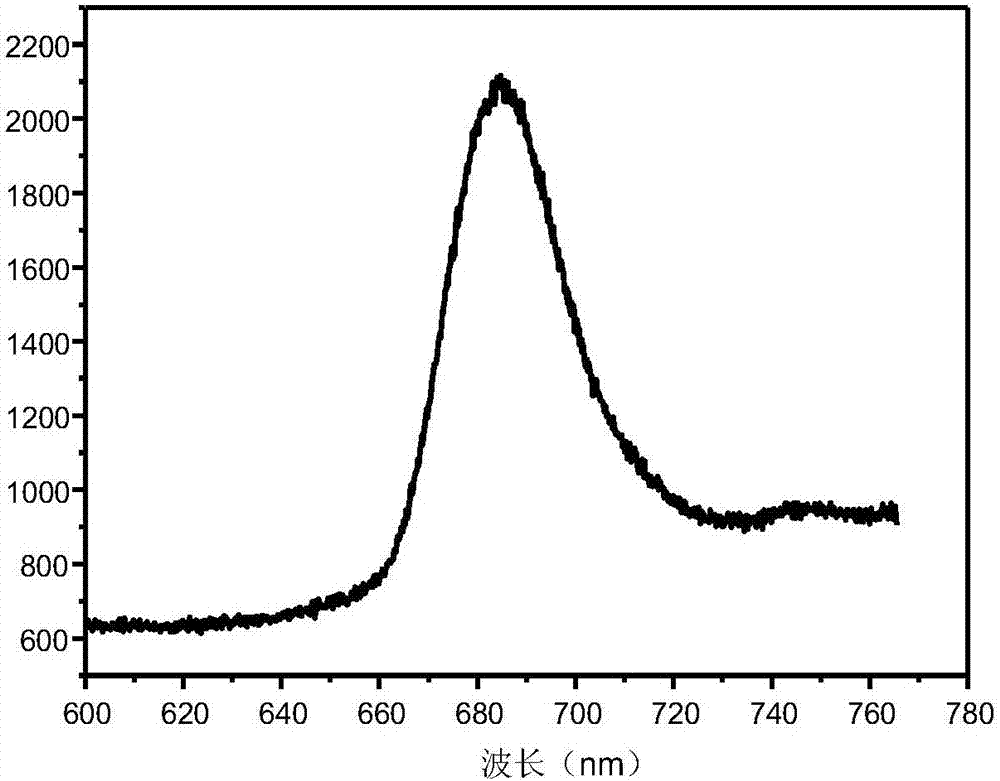

[0039] Example 2 Glutathione was dissolved in formamide to prepare a solution with a mass fraction of 3%. Take 50ml of the above solution and place it in a 100ml microwave reactor, then place the reactor in the microwave reactor, and take out the reactor after reacting at 180°C for 1 hour. After cooling to room temperature naturally, the reaction solution was diluted with water, dialyzed until there was no fluorescence in the dialysate, and the finally obtained solid, that is, the target product, was dried in a vacuum drying oven and sealed for storage. The fluorescence spectrum figure of the carbon dots obtained in this embodiment is as follows Figure 4As shown, the half width of the fluorescence emission peak is narrow, the fluorescence emission peak basically does not change with the wavelength of the excitation light, and has a large Stokes shift.

Embodiment 3

[0040] Example 3 Glutathione was dissolved in formamide to prepare a solution with a mass fraction of 3%. Take 50ml of the above solution and place it in a 100ml microwave reactor, then place the reactor in the microwave reactor, and take out the reactor after reacting at 180°C for 1 hour. After cooling to room temperature naturally, the reaction solution was centrifuged, and the obtained precipitate was washed 4 times with acetone and methanol respectively, and the finally obtained solid, that is, the target product, was dried in a vacuum oven and sealed for storage. The fluorescence spectrum figure of the carbon dots obtained in this embodiment is as follows Figure 5 As shown, the half width of the fluorescence emission peak is narrow, the fluorescence emission peak basically does not change with the wavelength of the excitation light, and has a large Stokes shift.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com