A kind of denitrification functional filter material prepared by ring-opening polymerization method

A technology of composite filter material and denitrification catalyst, which is applied in the field of preparation of high-efficiency denitrification functional filter material, can solve the problems of not involving chemical reactions and not particularly good firmness, and achieves reaction synthesis method and simple operation, short test period, and protection Thin and firm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

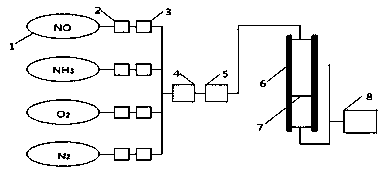

Method used

Image

Examples

Embodiment 1

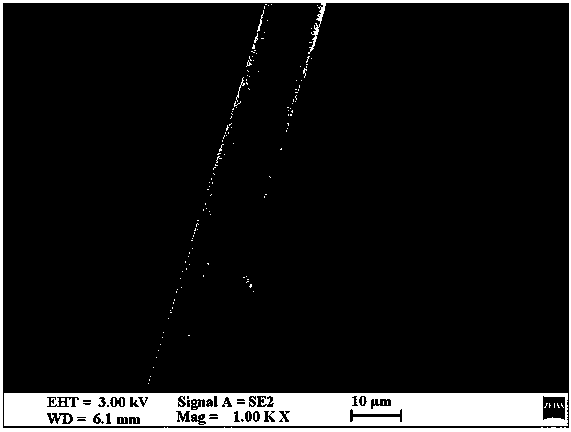

[0023] First weigh 32ml of concentrated nitric acid and add it to 68ml of deionized water to prepare a dilute nitric acid solution with a volume fraction of 30%. Then put two pieces of polyphenylene sulfide (PPS), and treat it in a water bath at 80°C for 2 hours. After the treatment, clean the PPS with deionized water and ethanol, and then dry the filter material in an oven for later use.

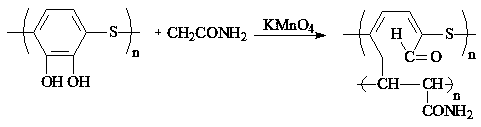

[0024] Add 1.2g of acrylamide to a beaker containing 50ml of deionized water, stir evenly, accurately weigh the mass of the above-mentioned filter material to 0.6g, then add the above-mentioned treated PPS to the prepared solution, and place it at room temperature for ultrasonic dispersion for 2 hours. After the surface of PPS is fully wrapped by acrylamide, move it into a water bath, and then pass in protective gas nitrogen until the reaction bottle is filled with nitrogen, accurately weigh 0.12g of potassium permanganate, and prepare KMnO with a concentration of 0.02M 4 solution, slowly p...

Embodiment 2

[0027] First weigh 32ml of concentrated nitric acid and add it to 68ml of deionized water to make a 30% (v / v) dilute nitric acid solution. Then put two pieces of polyphenylene sulfide (PPS), and treat it in a water bath at 80°C for 2 hours. After the treatment, clean the PPS with deionized water and ethanol, and then dry the filter material in an oven for later use.

[0028] Add 1.8g of acrylamide to a beaker containing 50ml of deionized water, stir evenly, accurately weigh the mass of the above-mentioned filter material to 0.6g, then add the above-mentioned treated PPS to the prepared solution, and place it at room temperature for ultrasonic dispersion for 2 hours. After the surface of PPS is fully wrapped by acrylamide, move it into a water bath, and then pass in protective gas nitrogen until the reaction bottle is filled with nitrogen, accurately weigh 0.12g of potassium permanganate, and prepare KMnO with a concentration of 0.02M 4 solution, slowly pour the prepared soluti...

Embodiment 3

[0031] First weigh 32ml of concentrated nitric acid and add it to 68ml of deionized water to make a 30% (v / v) dilute nitric acid solution. Then put two pieces of polyphenylene sulfide (PPS), and treat it in a water bath at 80°C for 2 hours. After the treatment, clean the PPS with deionized water and ethanol, and then dry the filter material in an oven for later use.

[0032] Add 2.4g of acrylamide to a beaker containing 50ml of deionized water, stir evenly, accurately weigh the mass of the above-mentioned filter material to 0.6g, then add the above-mentioned treated PPS to the prepared solution, and place it at room temperature for ultrasonic dispersion for 2 hours. After the surface of PPS is fully wrapped by acrylamide, move it into a water bath, and then pass in protective gas nitrogen until the reaction bottle is filled with nitrogen, accurately weigh 0.12g of potassium permanganate, and prepare KMnO with a concentration of 0.02M 4 solution, slowly pour the prepared solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com