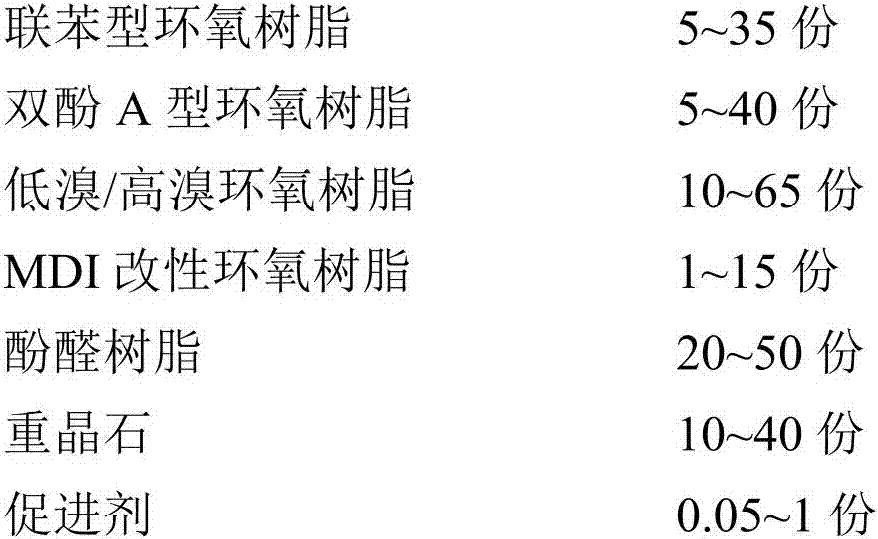

CAF-resistant, high-Tg and high-heat-resistance resin composition for copper-clad plate of automobiles

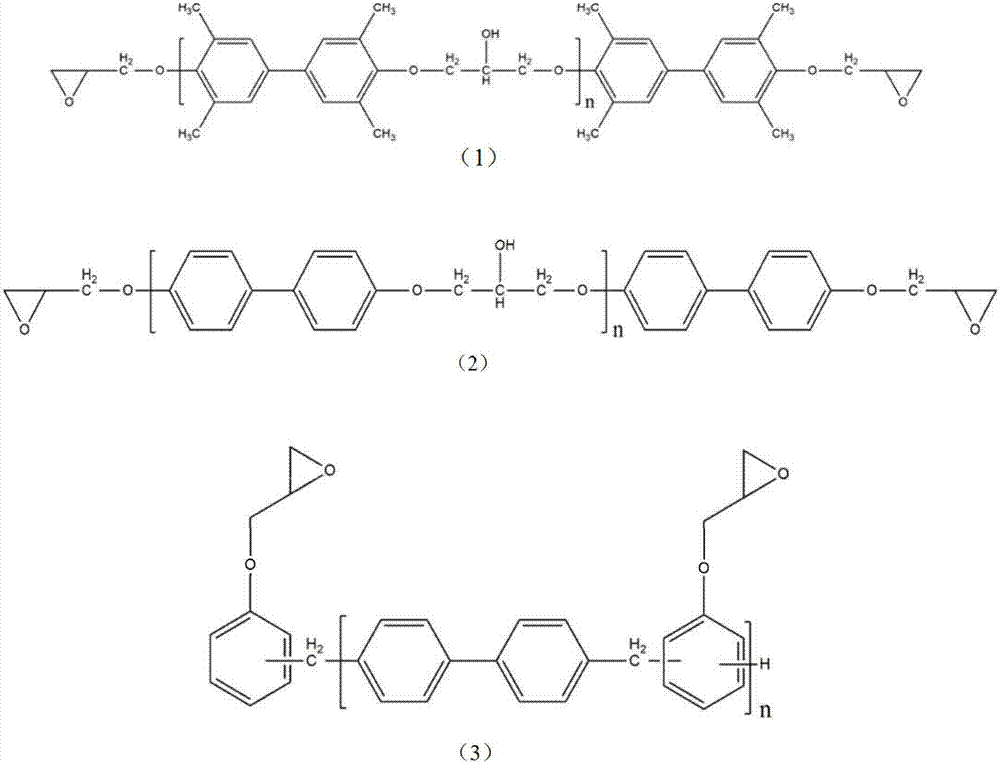

A technology of resin composition and copper clad laminate, which is applied in the field of high heat-resistant resin composition, CAF resistance, and high Tg, and can solve the problems of slow development, limited promotion and application range, and low comprehensive performance of products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

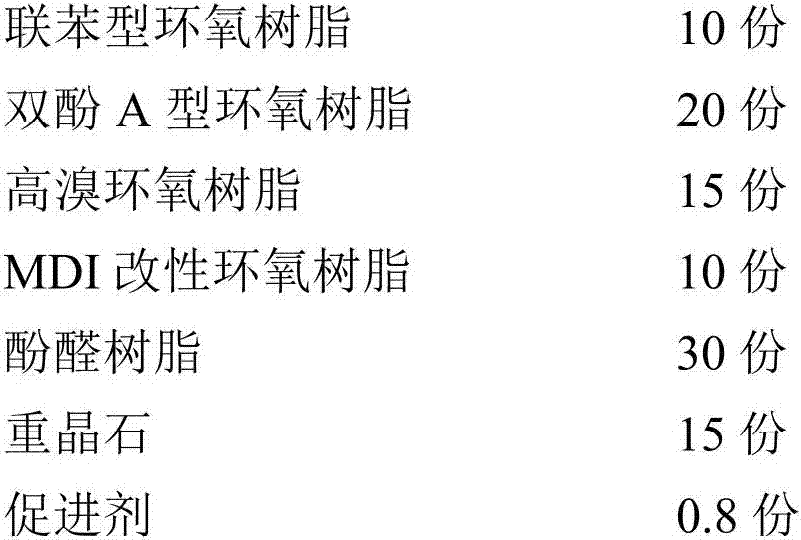

[0023] The CAF-resistant, high-Tg, and high-heat-resistant resin composition of this embodiment, based on solids weight, includes the following components: 10 parts of YX4000 biphenyl type epoxy resin, 20 parts of bisphenol A type epoxy resin, high 15 parts of bromine epoxy resin, 10 parts of MDI modified epoxy resin, 30 parts of bisphenol A phenolic resin, 15 parts of barite, 0.8 parts of 2-phenylimidazole.

Embodiment 2

[0025] The CAF-resistant, high-Tg, and high-heat-resistant resin composition of this embodiment, based on solids weight, includes the following components: No. YL612 biphenyl type epoxy resin 12 parts, bisphenol A type epoxy resin 18 parts, high 18 parts of bromine epoxy resin, 7 parts of MDI modified epoxy resin, 35 parts of phenolic phenolic resin, 10 parts of barite, 0.2 part of 2-ethyl-4-methylimidazole, 0.3 part of 2-methylimidazole.

Embodiment 3

[0027] The CAF-resistant, high-Tg, and high-heat-resistant resin composition of this embodiment, based on solids weight, includes the following components: No. NC3000 biphenyl type epoxy resin 8 parts, phenol-para-xylene type epoxy resin 20 parts , 20 parts of phenol type phenolic epoxy resin, 25 parts of phosphorus-containing phenolic resin, 15 parts of o-cresol type phenolic resin, 12 parts of barite, 0.5 parts of 2-phenylimidazole and 2-methylimidazole.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com