Method for preparing polyhexamethylene glycol/ terminal hydroxyl multi-wall carbon nanotube nanocomposite film

A technology of polyethylene adipate and multi-wall carbon nanotubes is applied in the field of preparing polyethylene adipate/hydroxyl-terminated multi-wall carbon nanotube nanocomposite films, which can solve the problem of low crystallinity and slow forming rate. , thermal stability and poor physical and mechanical properties, to achieve the effect of increasing added value, increasing crystallization temperature, and shortening molding cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

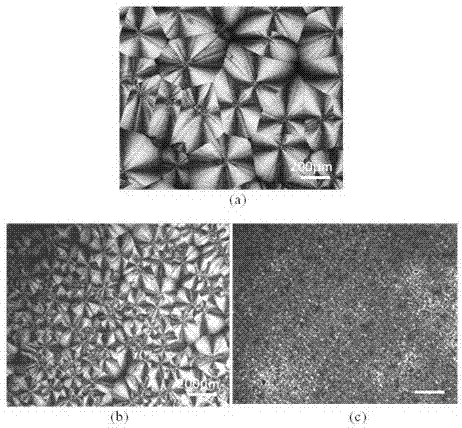

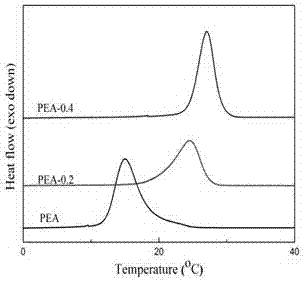

[0017] Example 1 (Example 1 is a comparative example, which is a composite film prepared under the condition of endless hydroxyl multi-walled carbon nanotubes):

[0018] 1) Take out the hydroxyl-terminated multi-walled carbon nanotubes after vacuum drying for 3 days, weigh 0.000g of hydroxyl-terminated multi-walled carbon nanotubes and place them in 10mL of N,N-dimethylformamide (DMF) solvent, and ultrasonically disperse them for 1h ;

[0019] 2) Weigh 0.5g polyethylene adipate glycol and dissolve it in 10mL DMF;

[0020] 3) Mix the two solutions obtained in step 1) and step 2) at a ratio of 0.5:0.000, mechanically stir for 30 minutes and continue to use ultrasonic dispersion for 2 hours, and finally mix the hydroxyl-terminated multi-walled carbon nanotubes with polyethylene adipate glycol Evenly, pure polyethylene adipate glycol casting solution is obtained;

[0021] 4) Pipette the casting solution and solidify it into a blended film on a constant temperature hot stage at 4...

Embodiment 2

[0025] 1) Take out the hydroxyl-terminated multi-walled carbon nanotubes after vacuum drying for 3 days, weigh 0.001g of hydroxyl-terminated multi-walled carbon nanotubes and put them into 10ml of N,N-dimethylformamide (DMF) solvent, and ultrasonically disperse for 1h ;

[0026] 2) Weigh 0.5g polyethylene adipate glycol and dissolve it in 10mL DMF;

[0027] 3) Mix the two solutions obtained in step 1) and step 2) at a ratio of 0.5:0.001, mechanically stir for 30 minutes and continue to use ultrasonic dispersion for 2 hours, and finally mix the hydroxyl-terminated multi-walled carbon nanotubes with polyethylene adipate glycol Uniformly, obtain the casting film solution that ratio is 0.2% polyethylene adipate / hydroxyl-terminated multi-walled carbon nanotubes;

[0028] 4) Pipette the casting solution and solidify it into a blended film on a constant temperature hot stage at 20°C;

[0029] 5) The blend film prepared in step 4) was melted on a constant temperature hot stage at 80...

Embodiment 3

[0032] 1) Take out the hydroxyl-terminated multi-walled carbon nanotubes after vacuum drying for 3 days, weigh 0.002g of hydroxyl-terminated multi-walled carbon nanotubes and place them in 10mL of N,N-dimethylformamide (DMF) solvent, and ultrasonically disperse them for 1h ;

[0033] 2) Weigh 0.5g polyethylene adipate glycol and dissolve it in 10mL DMF;

[0034] 3) Mix the two solutions obtained in step 1) and step 2) at a ratio of 0.5:0.002, mechanically stir for 30 minutes and continue to use ultrasonic dispersion for 2 hours, and finally mix the hydroxyl-terminated multi-walled carbon nanotubes with polyethylene adipate glycol Uniformly, the obtained ratio is 0.4% polyethylene adipate / hydroxyl-terminated multi-walled carbon nanotube casting solution;

[0035] 4) Pipette the casting solution and solidify it on a 30°C constant temperature hot stage to form a blended film;

[0036] 5) The blend film prepared in step 4) was melted on a constant temperature hot stage at 80 °C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com