A kind of lubricating oil additive for fullerene application

A lubricating oil additive, fullerene technology, applied in the directions of additives, lubricating compositions, petroleum industry, etc., to achieve the effects of strong adsorption, low wear and strong oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

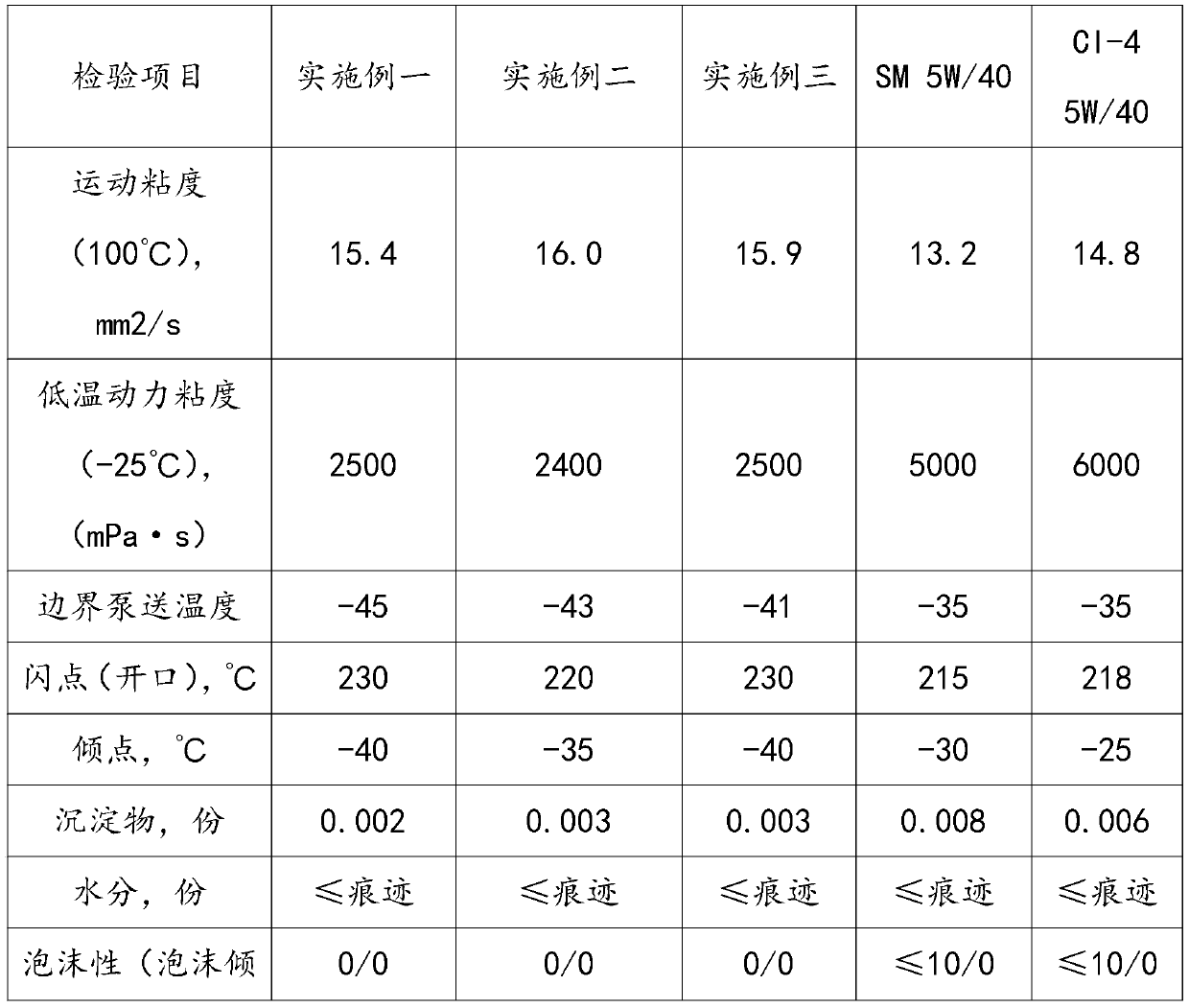

Embodiment 1

[0022] A lubricating oil additive for fullerene applications, including the following raw materials in parts by weight: base oil 60 parts to 63 parts, fullerene 8.4 parts to 10.1 parts, oil-soluble yellow 0.5 parts to 1.50 parts, viscosity adjustment 4.0 parts -4.4 parts of antioxidants, 0.1 parts -1.5 parts of antioxidants, 0.2 parts -0.8 parts of dispersants, 0.1 parts -0.5 parts of reinforcing agents, 5.1 parts -8.4 parts of modified calcite powder, 7.4 parts of nano silica- 8.2 parts, 0.2-0.4 parts of oleic acid, and 1.2-1.6 parts of sodium methyl silicate.

[0023] A method for preparing lubricating oil additives for fullerene applications includes the following steps:

[0024] 1) After mixing 5.1 parts -8.4 parts of modified calcite powder, 7.4 parts-8.2 parts of nano silica and 1.2 parts-1.6 parts of sodium methyl silicate with a mixer, add 20 parts of base oil to them. Parts, 8.4 parts to 10.1 parts of fullerene and 0.5 parts to 1.50 parts of oil-soluble yellow, and finall...

Embodiment 2

[0027] A lubricating oil additive for fullerene applications, including the following raw materials in parts by weight: 60 parts of base oil, 8.4 parts of fullerene, 0.5 part of oil-soluble yellow, 4.0 parts of viscosity modifier, and 0.1 part of antioxidant , 0.2 parts of dispersant, 0.1 parts of reinforcing agent, 5.1 parts of modified calcite powder, 7.4 parts of nano silica, 0.2 parts of oleic acid and 1.2 parts of sodium methyl silicate.

[0028] A method for preparing lubricating oil additives for fullerene applications is characterized in that it comprises the following steps:

[0029] 1) After fully mixing 5.1 parts of modified calcite powder, 7.4 parts of nano silica and 1.2 parts of sodium methyl silicate with a mixer, add 20 parts of base oil, 8.4 parts of fullerene and 0.5 parts of oil-soluble yellow to them. Kneading in a kneader for 10-30 minutes for use;

[0030] 2) Add 4.0 parts of viscosity modifier, 0.1 part of antioxidant, 0.1 part of dispersant, 0.1 part of reinf...

Embodiment 3

[0032] A lubricating oil additive for fullerene applications, including the following raw materials in parts by weight: 63 parts of base oil, 10.1 parts of fullerene, 1.50 parts of oil-soluble yellow, 4.4 parts of viscosity modifier, 1.5 parts of antioxidant , 0.8 parts of dispersant, 0.5 parts of reinforcing agent, 8.4 parts of modified calcite powder, 8.2 parts of nano silica, 0.4 parts of oleic acid and 1.6 parts of sodium methyl silicate.

[0033] A method for preparing lubricating oil additives for fullerene applications is characterized in that it comprises the following steps:

[0034] 1) After 8.4 parts of modified calcite powder, 8.2 parts of nano silica and 1.6 parts of sodium methyl silicate are thoroughly mixed with a mixer, 23 parts of base oil, 10.1 parts of fullerene and 1.50 of oil-soluble yellow are added to it. Kneading in a kneader for 10-30 minutes for use;

[0035] 2) Add 4.4 parts of viscosity modifier, 1.5 parts of antioxidants, 1.5 parts of dispersants, 0.5 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| brittleness temperature | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com