Recombinant Bacillus subtilis for expressing L.mesenteroides sourced sucrose phosphorylase

A technology of Bacillus subtilis and sucrose phosphorylase, which is applied in the fields of genetic engineering and enzyme engineering, and can solve the problems of incompatibility and the easy production of endotoxin by Escherichia coli

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

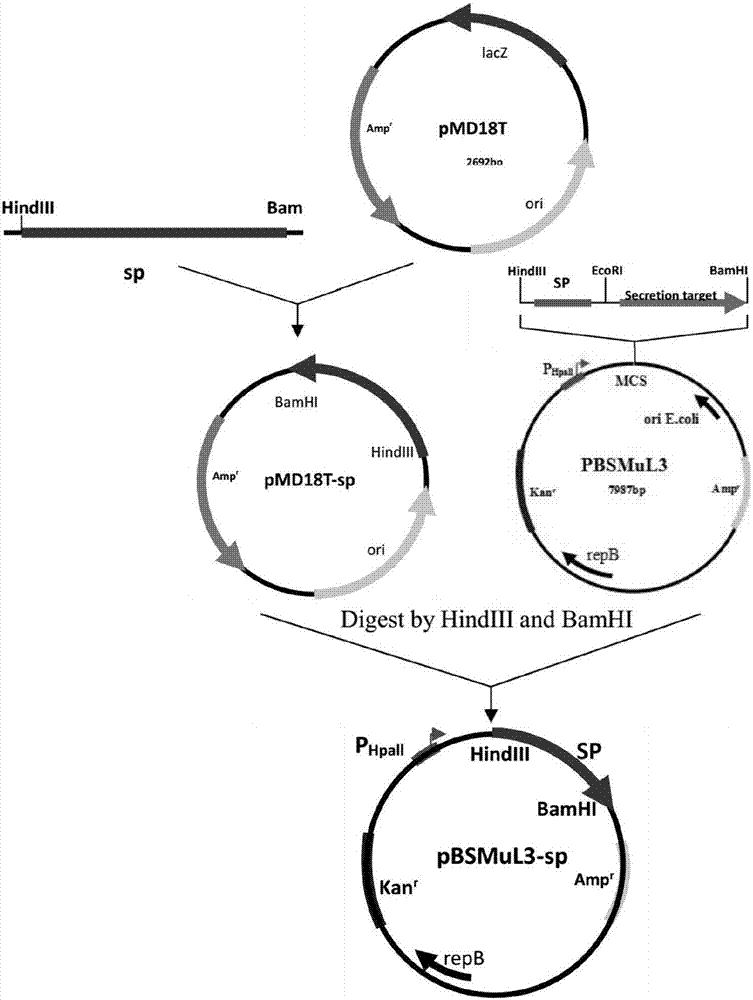

[0040] Example 1: Cloning of the Leuconostoc enteroconostoc sucrose phosphorylase-encoding gene and construction of an expression vector

[0041] according to figure 1 According to the process of constructing the expression vector, primers F and R were designed according to the synthetic sucrose phosphorylase gene:

[0042] F: 5'-GCGAAGCTTAAGGAGGATATTATGGAAATTCAGAACAAGGC-3'

[0043] R: 5'-GCGGGATCCTTAATTCTGGGTCAGATTATCGC-3'

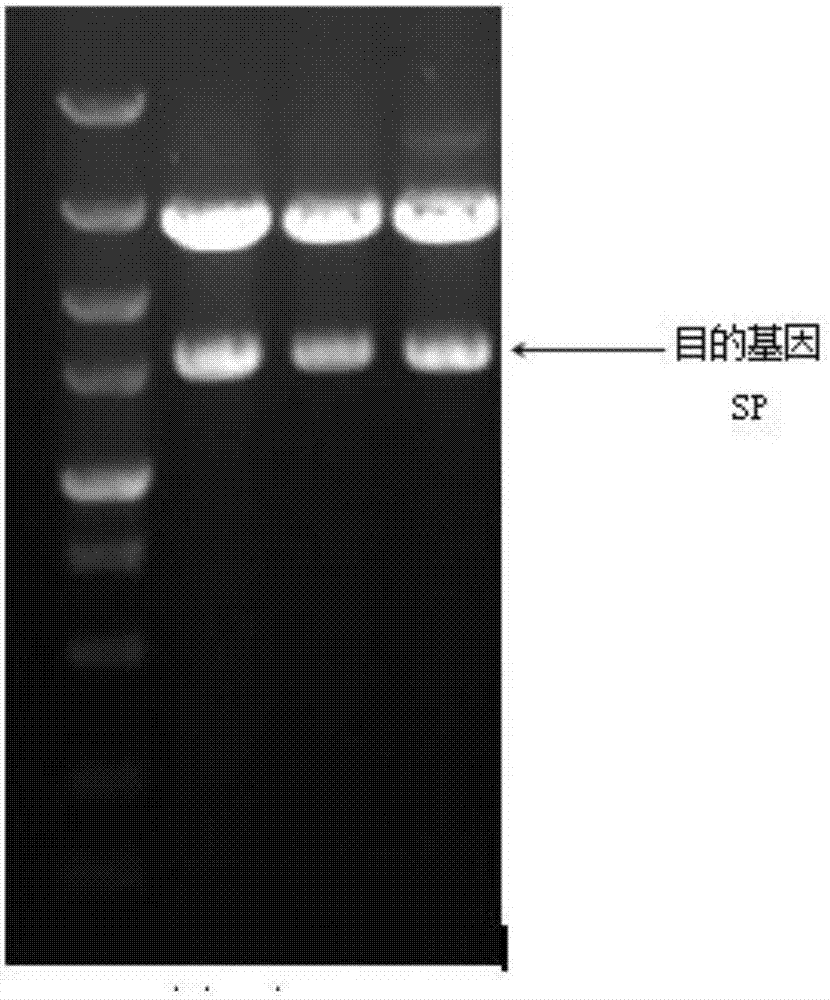

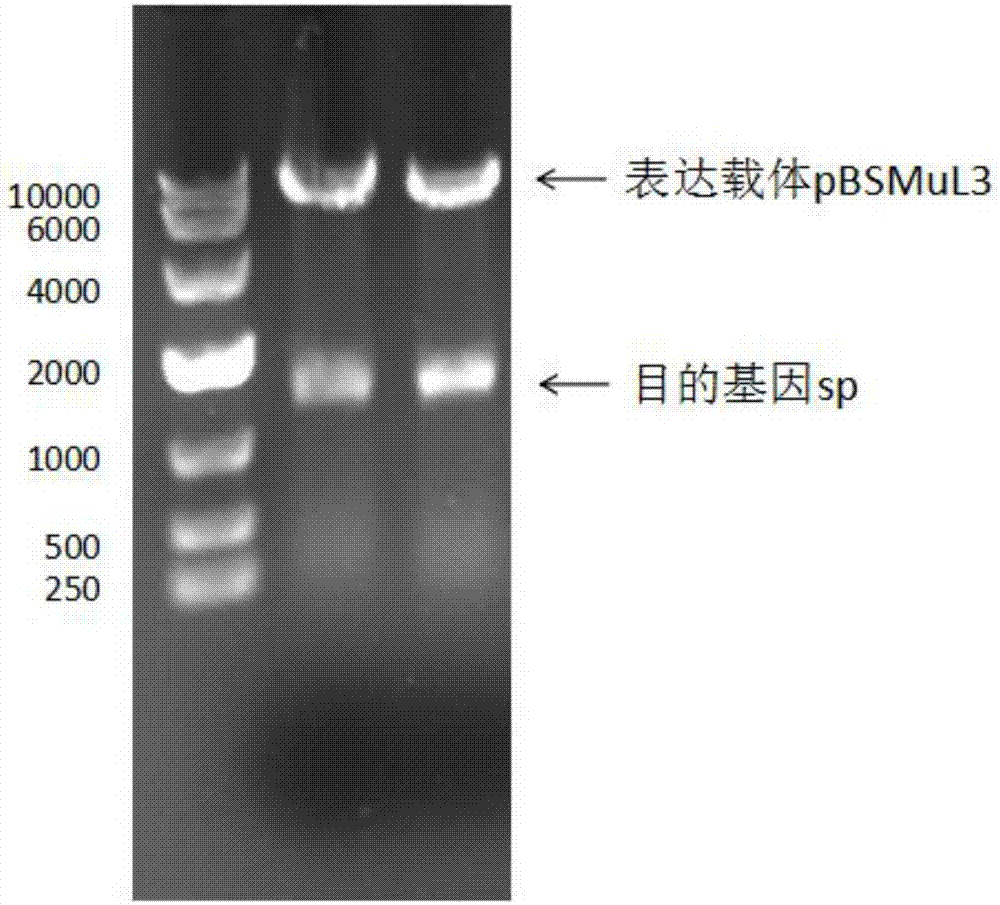

[0044]The restriction sites are indicated by underlined letters. The PCR system is: 20 μM primers F and R 0.5 μL each, dNTPMix 4 μL, 5×PS Buffer 10 μL, 2.5 U / μL PrimeStar polymerase 0.5 uL, template 0.5 μL, add double distilled water to make up 50 μL. PCR conditions: pre-denaturation at 94°C for 4min; denaturation at 98°C for 10s, annealing at 55°C for 10s, extension at 72°C for 1min and 50s, 30 cycles. The PCR product was gel-recovered, purified by adding A, and then ligated with the cloning vector pMD-18T. The target gene was recovered by enzyme dig...

Embodiment 2

[0045] Embodiment 2: Transformation of recombinant plasmid pBSMuL3-sp

[0046] 1) Fresh LB plate (LB solid medium: peptone 10g / L, yeast extract 5g / L, NaCl 10g / L, 0.2g / L agar powder) pick a single colony of Bacillus subtilis (preservation number is CCTCC M 2016536) Inoculate in 5ml LB liquid medium, culture at 37°C, 200rpm for 10h.

[0047] 2) Take 2.5 mL and transfer it into 40 mL LB medium with 0.5 M sorbitol, culture at 37° C. with shaking at 200 rpm for four hours.

[0048] 3) Take all the bacteria liquid and bathe in ice water for 10 minutes, then centrifuge at 5000 rpm and 4°C for 5 minutes to collect the bacteria.

[0049] 4) Wash the cells with 40ml of pre-cooled electroporation buffer (sorbitol 0.5M, mannitol 0.5M, glucose 10%), centrifuge at 5000rpm, 4°C for 5min to remove the supernatant, and rinse 4 times in this way.

[0050] 5) Resuspend the washed bacteria in 1 mL of electroporation medium, aliquot them into 1.5 mL EP tubes, and fill each tube with 300 μl of co...

Embodiment 3

[0053] Embodiment 3: shake flask fermentation to produce enzyme

[0054] The recombinant Bacillus subtilis strain obtained in Example 2 was inoculated in LB medium, and after culturing at 37°C for 8 hours, it was transferred to TB fermentation medium with 5% inoculation amount, and then cultured at 37°C and 200 rpm for 2 hours. , and then moved to 33 ℃ constant temperature culture for 48h to produce enzymes. After the fermentation, the supernatant collected by centrifugation is the crude enzyme liquid.

[0055] LB medium (g / L): peptone 10, yeast extract 5, NaCl 10.

[0056] TB medium (g / L): peptone 10, yeast powder 24, glycerol 5, K 2 HPO 4 ·3H 2 O 16.43, KH 2 PO 4 2.31.

[0057] The enzyme activity in the crude enzyme solution was measured, and the result showed that the enzyme activity was 136U / mL. The results of protein electrophoresis showed that there was a band consistent with the theoretical molecular weight at 53kDa ( Figure 4 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com