Colored photosensitive resin composition, color filter and image display device manufactured using the same

A technology of photosensitive resin and composition, applied in chemical instruments and methods, photosensitive materials for photomechanical equipment, instruments, etc., capable of solving the problems of variation, gelling, storage stability, brightness and contrast of pigment dispersion compositions Achieve the effect of excellent contrast or brightness without reducing optical properties and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

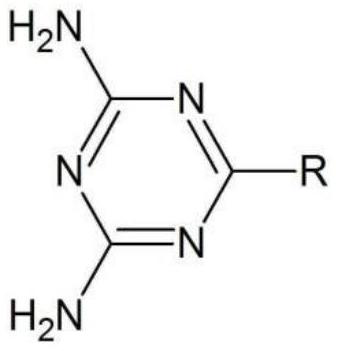

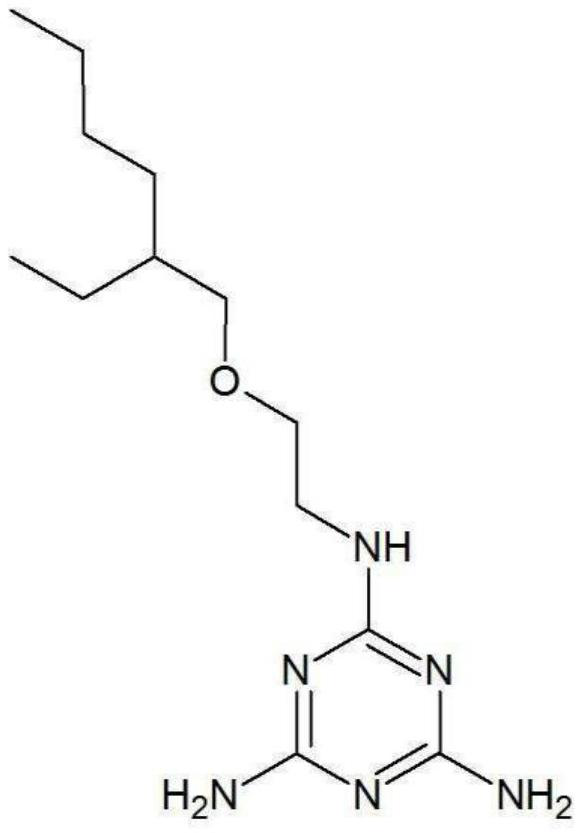

[0130] Synthesis Example 1: Triazine Compound 1

[0131] Add 18.4 parts by weight of 2-chloro-4,6-diamino-1,3,5-triazine and 21 parts by weight of 3-(2-ethylhexyloxy)propylamine to 100 parts by weight of water. Reacted for 1 hour. The obtained reactant was reacted at 85° C. for 5 hours. The residue obtained by leaching the obtained reactant was washed with water, and then left to stand overnight in a thermostat at 100° C. to dry, thereby obtaining a compound of the following chemical formula 2.

[0132] [chemical formula 2]

[0133]

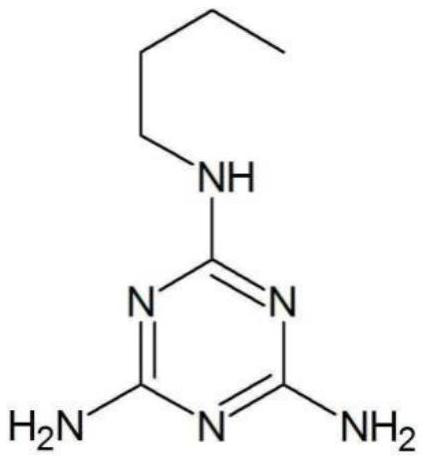

Synthetic example 2

[0134] Synthesis Example 2: Triazine Compound 2

[0135] 18.4 parts by weight of 2-chloro-4,6-diamino-1,3,5-triazine and 21 parts by weight of butylamine were added to 100 parts by weight of water, and reacted at 10° C. for 1 hour. The obtained reactant was reacted at 85° C. for 5 hours. The residue obtained by leaching the obtained reactant was washed with water, then left to stand overnight in a thermostat at 100° C., and dried to obtain a compound of the following chemical formula 3.

[0136] [chemical formula 3]

[0137]

Synthetic example 3

[0138] Synthesis Example 3: Triazine Compound 3

[0139] After adding 18.4 parts by weight of 2-chloro-4,6-diamino-1,3,5-triazine and 21 parts by weight of 1,3-butanediol to 100 parts by weight of water, and adding 10 parts by weight of sodium hydroxide , and allowed to react at 10°C for 3 hours. The obtained reactant was reacted at 85° C. for 5 hours. The residue obtained by leaching the obtained reactant was washed with water, then left to stand overnight in a thermostat at 100° C., and dried to obtain a compound of the following chemical formula 4.

[0140] [chemical formula 4]

[0141]

[0142] Resin (B-1)

[0143] A flask equipped with a stirrer, a thermometer, a reflux condenser, a dropping funnel, and a nitrogen introduction tube was prepared. On the other hand, as a monomer dropping funnel, 74.8 g (0.20 mol) of benzylmaleimide and 43.2 g of acrylic acid were put in. (0.30 mol), 118.0 g (0.50 mol) of vinyl toluene, 4 g of tert-butyl peroxy-2-ethylhexanoate, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com