Preparation method of horticultural nutrient soil using ecological organic fertilizer

A manufacturing method and technology of organic fertilizer, which is applied in the field of gardening materials, can solve the problems of non-sterilizing soil, plant damage, poor air permeability, etc., and achieve the effect of protecting human health and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

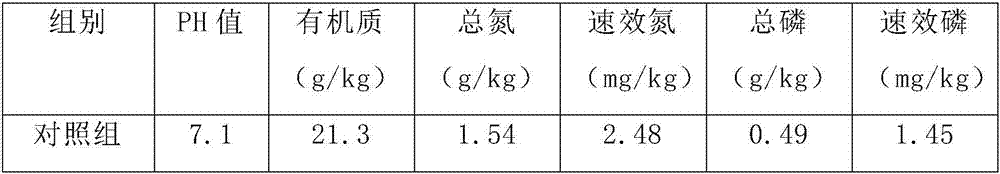

Examples

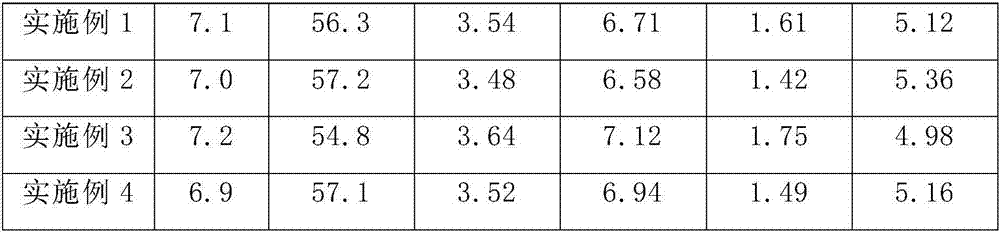

Embodiment 1

[0024] (1) Preparation of organic fertilizer: Crush weeds, leaves or other plant stalks to obtain plant material, weigh 70 parts of plant material according to the mass fraction, waste residue produced during the oil extraction process of rapeseed, sesame, soybean and peanut and other oil crops 40 parts, 5 parts of urea, 30 parts of water, mix and stir, then add 5 parts of the equal mass mixture of Bacillus subtilis strains and lignin-degrading bacteria strains, stir evenly, pile up the materials to be decomposed, and turn over once every 5 days , obtain the organic fertilizer after 25d.

[0025] (2) Planting matrix configuration: weigh 40 parts of peat soil, 20 parts of peat soil, 15 parts of perlite with a particle size of 3-6 mm, 15 parts of vermiculite, and medical stone with a particle size of 3-6 mm according to the parts by mass 5 parts, 15 parts of river sand, 30 parts of organic fertilizer, mix the above raw materials evenly to get the planting substrate.

[0026] (3...

Embodiment 2

[0029] (1) Preparation of organic fertilizer: crush weeds, leaves or other plant stalks to obtain plant material, weigh 80 parts of plant material according to the number of parts by mass, waste residue produced during the oil extraction process of rapeseed, sesame, soybean and peanut and other oil crops 50 parts, 8 parts of urea, 50 parts of water, mix and stir, then add 10 parts of an equal mass mixture of Bacillus subtilis strains and lignin-degrading bacteria strains, stir evenly, pile up the materials to be decomposed, and turn over once every 6 days , obtain the organic fertilizer after 30d.

[0030] (2) Planting matrix configuration: weigh 50 parts of peat soil, 25 parts of peat soil, 20 parts of perlite with a particle size of 3-6 mm, 20 parts of vermiculite, and medical stone with a particle size of 3-6 mm according to the parts by mass 10 parts, 20 parts of river sand, 40 parts of organic fertilizer, mix the above raw materials evenly to get the planting substrate. ...

Embodiment 3

[0034] (1) Preparation of organic fertilizer: crush weeds, leaves or other plant stalks to obtain plant material, weigh 75 parts of plant material according to the mass fraction, and waste residue produced during the oil extraction process of rapeseed, sesame, soybean and peanut and other oil crops 45 parts, 7 parts of urea, 40 parts of water, mix and stir, then add 7 parts of the equal mass mixture of Bacillus subtilis strains and lignin-degrading bacteria strains, stir evenly, pile up the materials to be decomposed, and turn over once every 5 days , Obtain the organic fertilizer after 27d.

[0035] (2) Planting matrix configuration: Weigh 45 parts of peat soil, 23 parts of peat soil, 17 parts of perlite with a particle size of 3-6 mm, 18 parts of vermiculite, and medical stone with a particle size of 3-6 mm according to the parts by mass 8 parts, 17 parts of river sand, 35 parts of organic fertilizer, mix the above raw materials evenly to get the planting substrate.

[0036...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com