Preparation method and application of cobalt sulfide having nano-lamella assembled three-dimensional annular micro-nano structure

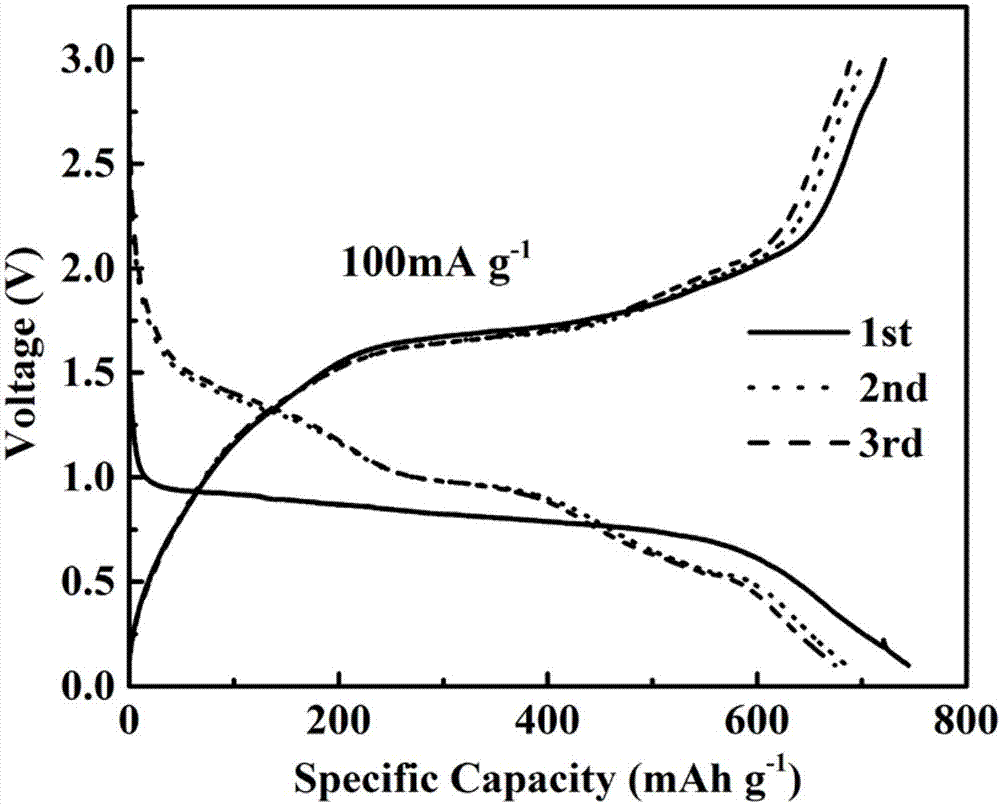

A micro-nano structure and nano-sheet technology, applied in cobalt sulfide, chemical instruments and methods, nanotechnology, etc., can solve problems such as volume change pulverization, structural collapse, unsatisfactory cobalt sulfide cycle performance and rate performance, etc., to achieve The effect of increasing tap density, improving electrochemical performance, and excellent sodium storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing cobalt sulfide with a three-dimensional annular micro-nano structure assembled by nanosheets, comprising the steps of:

[0028] 1) 1.5g CoCl 2 ·6H 2 O was added to 60ml of ethylenediamine, stirred for 80min to dissolve, and a mixed solution A was obtained, in which Co 2+ The concentration is 0.11mol / L;

[0029] 2) In the mixed solution A obtained in step 1), add 1.1 g of thioacetamide, stir for 80 min to dissolve it, and obtain mixed solution B, wherein Co 2+ The molar concentration ratio with thioacetamide is 0.43;

[0030] 3) Transfer the mixed solution B obtained in step 2) to a polytetrafluoroethylene-lined reactor, and react at 180° C. for 48 hours;

[0031] 4) Suction filter the product obtained in step 3), wash with deionized water and absolute ethanol for 4 times, and dry in a vacuum oven at 60°C for 12 hours to obtain a three-dimensional annular micro-nano-structure cobalt sulfide with nanosheet assembly .

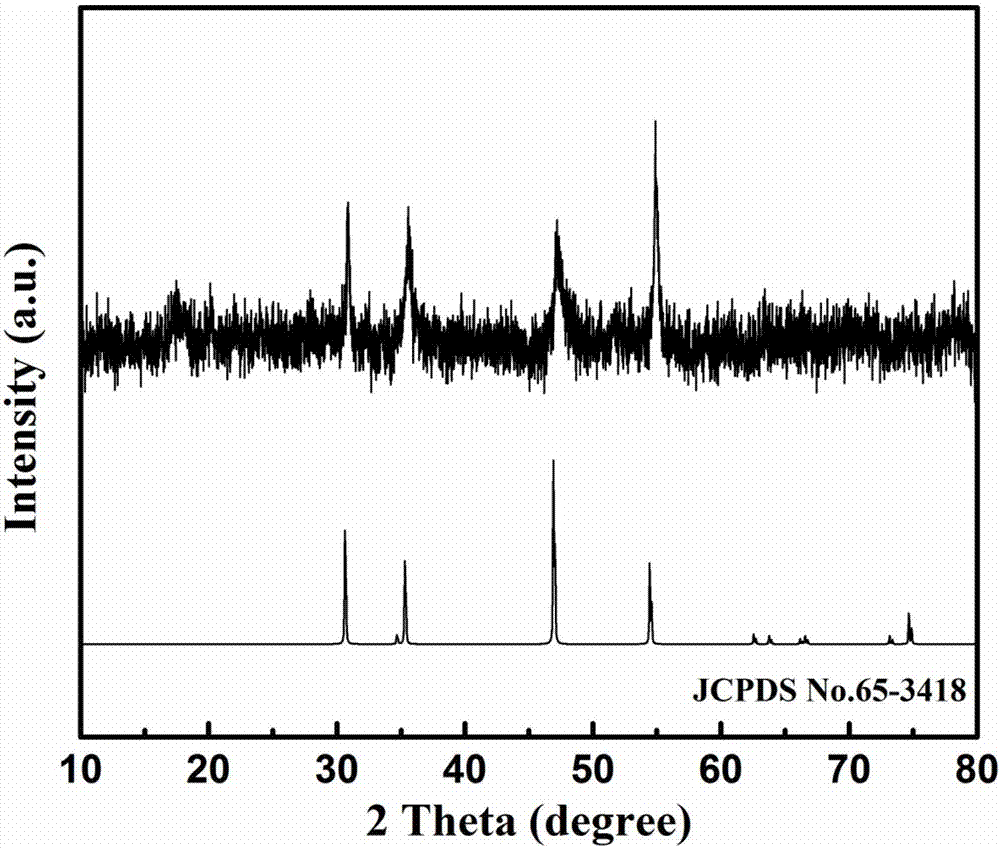

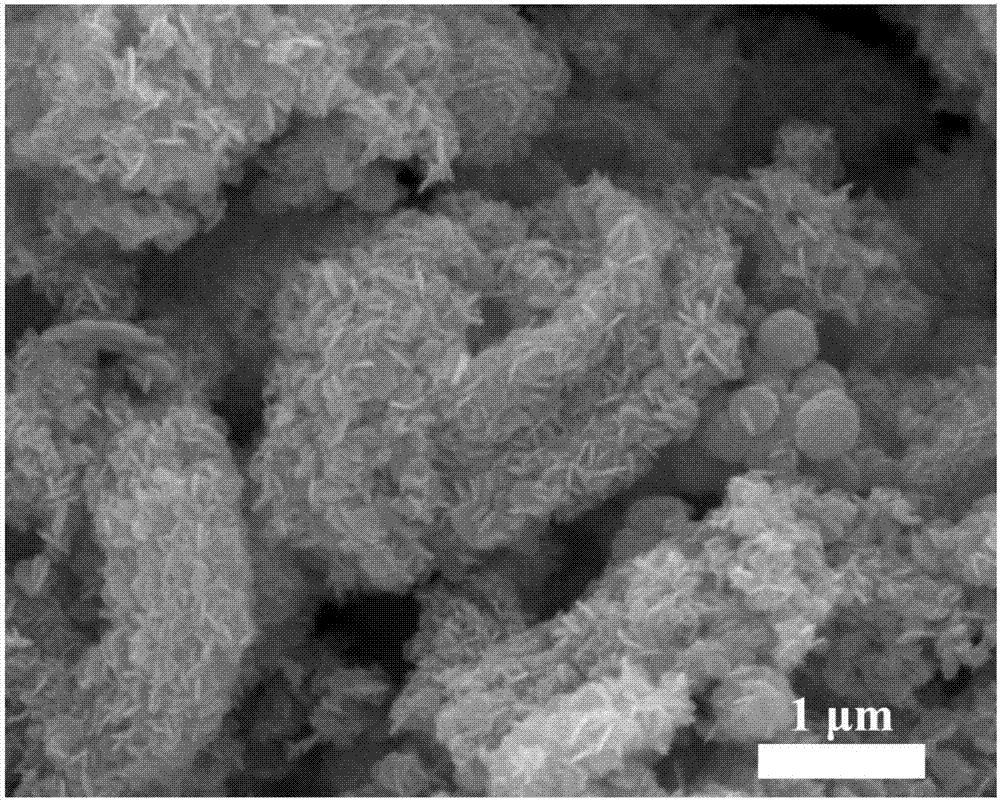

[0032] The crystal struc...

Embodiment 2

[0034] A method for preparing cobalt sulfide with a three-dimensional annular micro-nano structure assembled by nanosheets, comprising the steps of:

[0035] 1) 1.0g CoCl 2 ·6H 2 O was added to 60ml of ethylenediamine, stirred for 60min to dissolve, and mixed solution A was obtained, in which Co 2+ The concentration is 0.07mol / L;

[0036] 2) In the mixed solution A obtained in step 1), add 0.8g thioacetamide, stir for 60min to dissolve it, and obtain mixed solution B, wherein Co 2+ The molar concentration ratio with thioacetamide is 0.39;

[0037] 3) Transfer the mixed solution B obtained in step 2) to a polytetrafluoroethylene-lined stainless steel reactor, and react at 180° C. for 24 hours;

[0038] 4) Suction filter the product obtained in step 3), wash three times with deionized water and absolute ethanol, and dry in a vacuum oven at 60°C for 10 hours to obtain a three-dimensional annular micro-nano-structure cobalt sulfide with nanosheet assembly .

Embodiment 3

[0040] A method for preparing cobalt sulfide with a three-dimensional annular micro-nano structure assembled by nanosheets, comprising the steps of:

[0041] 1) 1.0g CoCl 2 6H2O was added to 40ml of ethylenediamine, stirred for 60min to dissolve, and mixed solution A was obtained, in which Co 2+ The concentration is 0.11mol / L;

[0042] 2) In the mixed solution A obtained in step 1), add 1.2 g of thioacetamide, stir for 80 min to dissolve it, and obtain mixed solution B, wherein Co 2+ The molar concentration ratio with thioacetamide is 0.26;

[0043] 3) Transfer the mixed solution B obtained in step 2) to a polytetrafluoroethylene-lined stainless steel reactor, and react at 180° C. for 48 hours;

[0044] 4) Suction filter the product obtained in step 3), wash three times with deionized water and absolute ethanol, and dry in a vacuum oven at 60°C for 10 hours to obtain a three-dimensional annular micro-nano-structure cobalt sulfide with nanosheet assembly .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com