Niobate system low-temperature sintered microwave dielectric ceramic material and preparation method thereof

A microwave dielectric ceramic and low-temperature sintering technology is applied in the field of niobate series low-temperature co-fired ceramic materials and their preparation, which can solve the problem of high sintering temperature and achieve the effect of reducing the sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

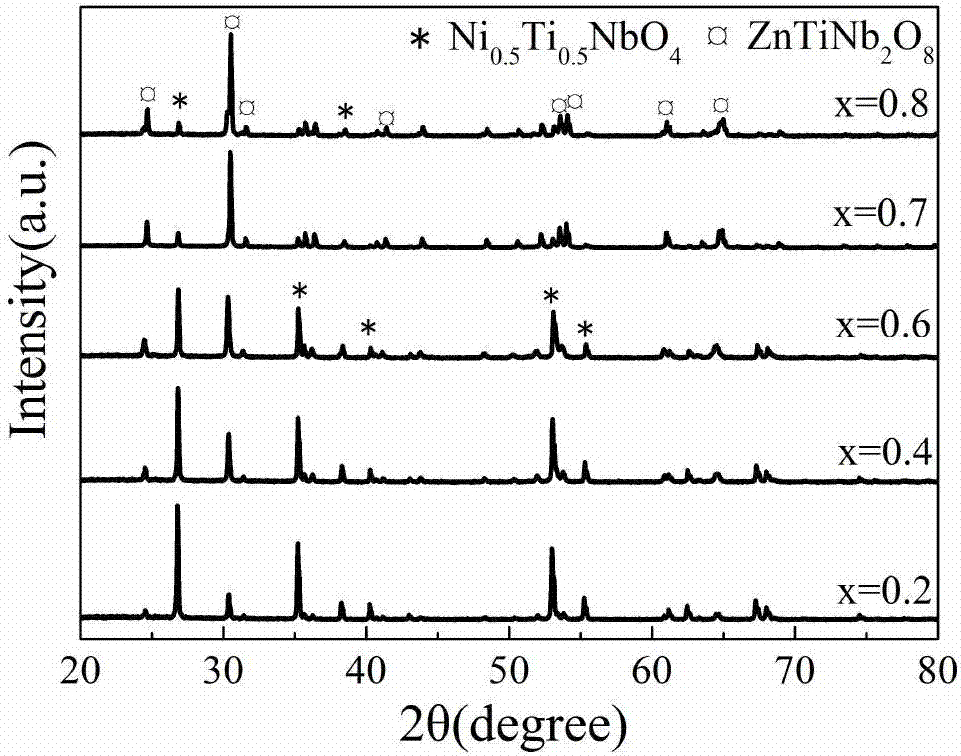

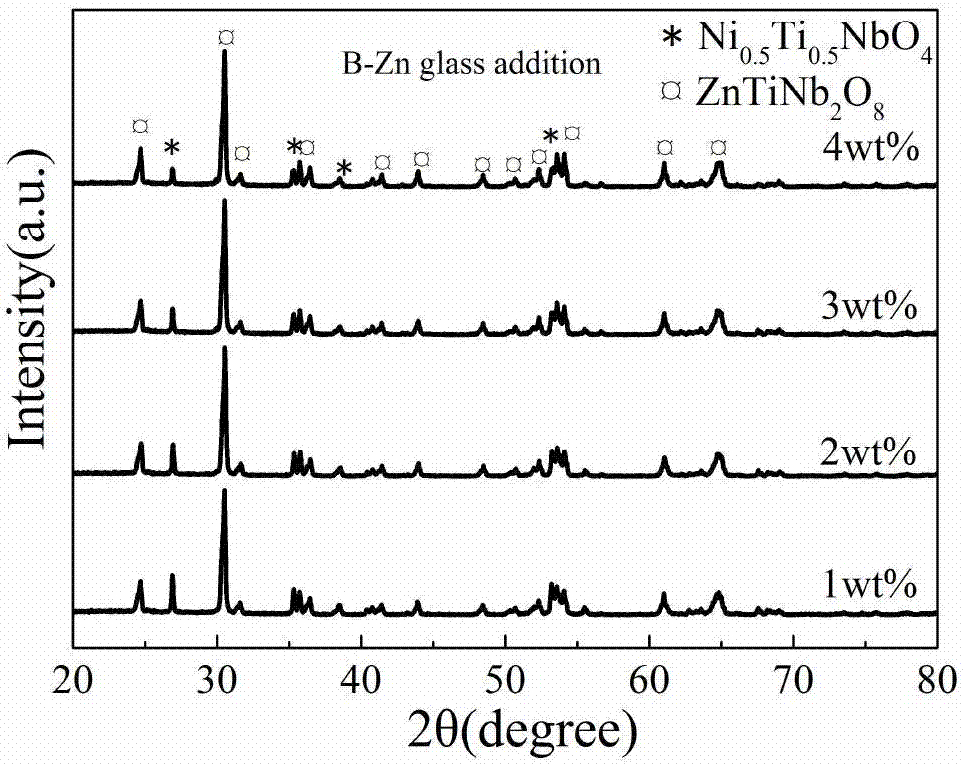

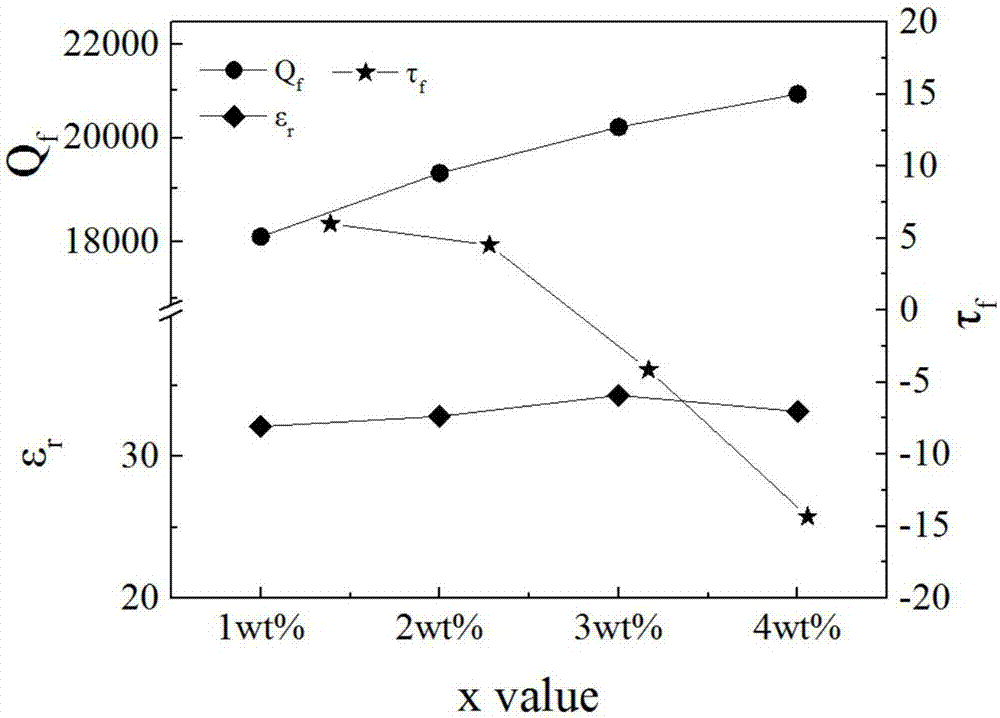

[0021] A niobate-based low-temperature sintered microwave dielectric ceramic material provided by the present invention comprises a main crystal phase and zinc-boron glass accounting for 1% to 4% by weight of the main crystal phase, and the main crystal phase is Ni 1-x Zn x TiNb 2 o 8 , wherein, 0.2≤x≤0.8; the content of the zinc-boron glass in terms of its standard substance is: ZnO 50mol%~70mol%, HBO 3 30mol% to 50mol%; the main crystal phase is added with zinc-boron glass accounting for 1% to 4% by weight of the main crystal phase, and after ball milling, drying, granulation, and dry pressing, the After sintering for 6-12 hours, the niobate-based low-temperature sintered microwave dielectric ceramic material is obtained.

[0022] A method for preparing a niobate-based low-temperature sintered microwave dielectric ceramic material, comprising the following steps:

[0023] Step 1, preparation of the main crystal phase: zinc oxide (ZnO), nickelous oxide (NiO), titanium dio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| resonant frequency temperature coefficient | aaaaa | aaaaa |

| sintering temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com