Method for preparing nodular micro-nano metal cone through electricity chemistry corrosion

A metal cone, micro-nano technology, applied in the field of precision displacement stage, can solve the problems of not being applied, difficult operation, and high device cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

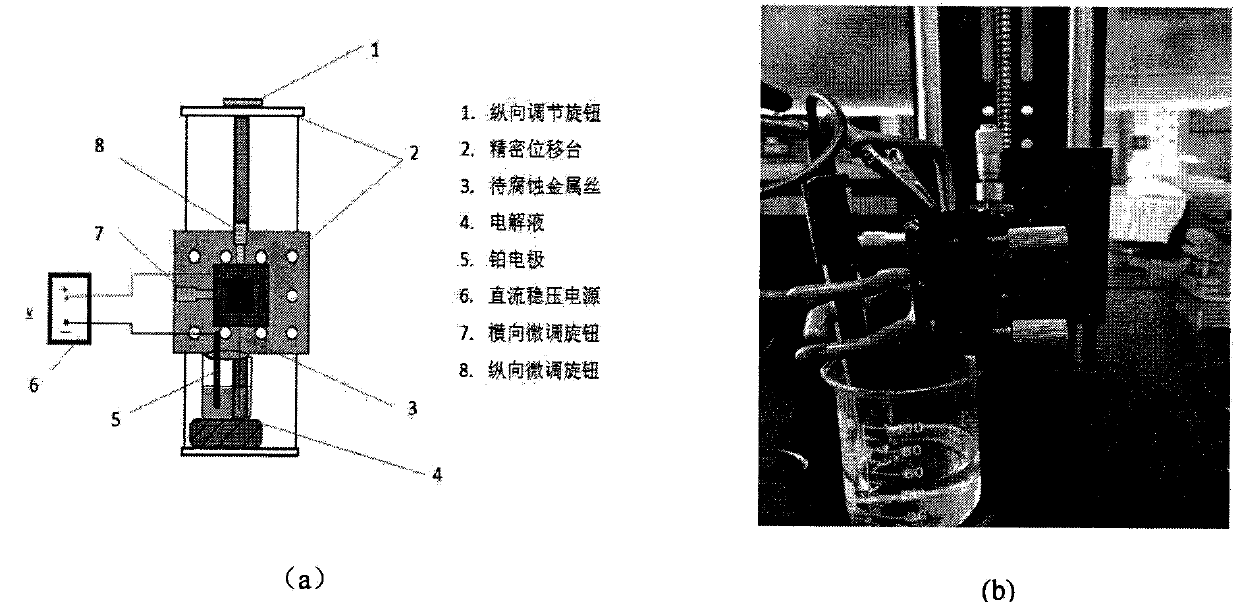

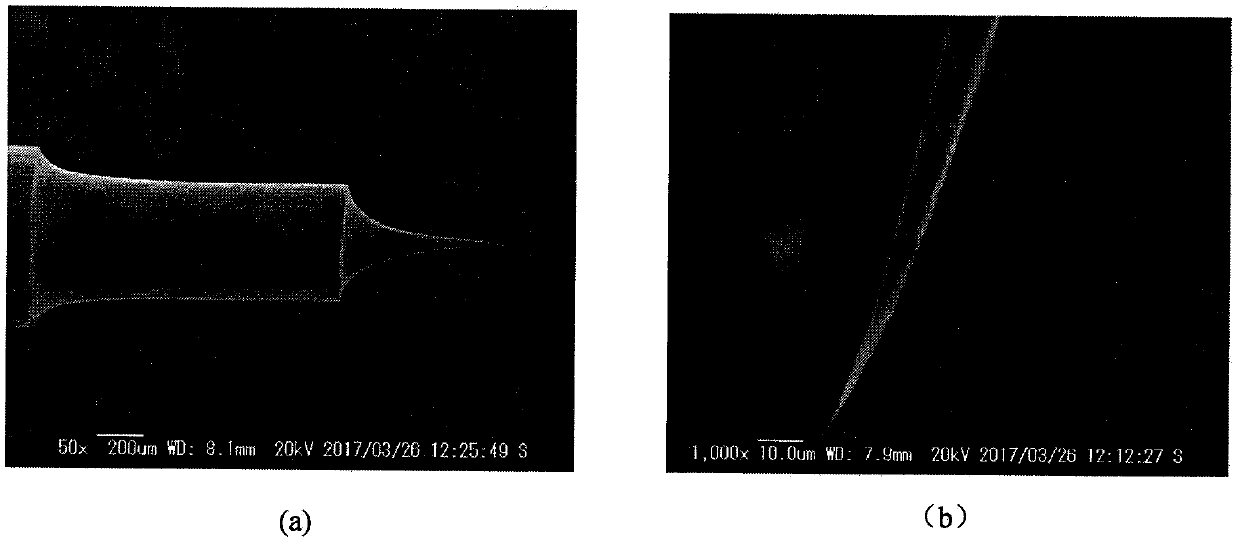

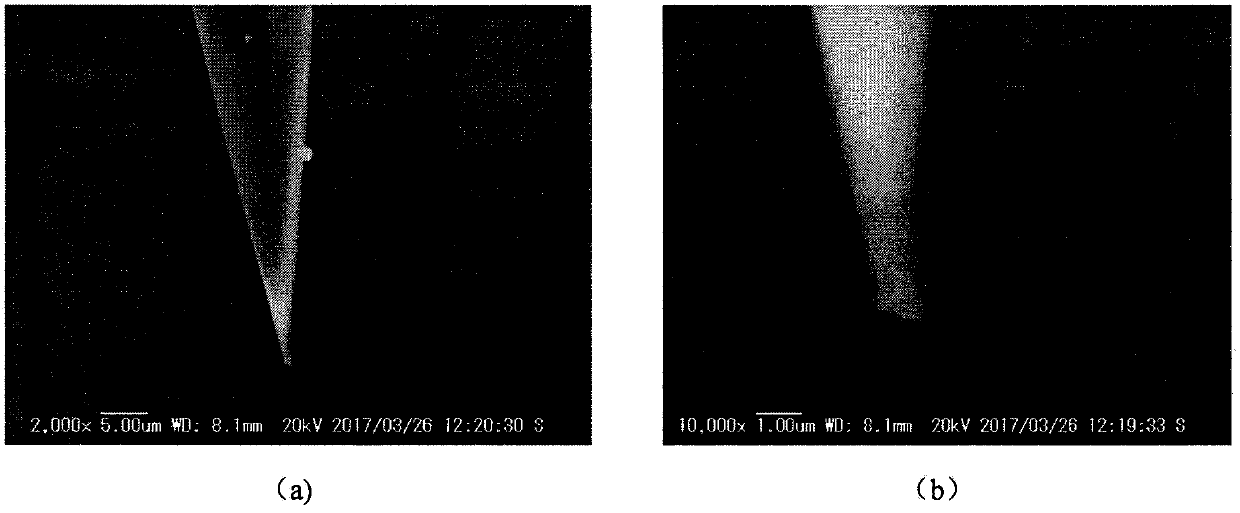

[0030] The following is a detailed description of the production of multi-section nonlinear aluminum nano-metal aluminum cones as an example in conjunction with the accompanying drawings:

[0031] The purity of the aluminum wire is 99.9999%, and the electrolyte is a 15.65% NAOH solution. The operation process is as follows:

[0032] First configure the NaOH electrolyte with a mass fraction of 15.65%. Place in a large beaker for later use.

[0033] Clamp the straight aluminum wire on the precision displacement stage, clamp the platinum electrode with a test tube clamp, put it into an empty small beaker, and keep it in a suspended state.

[0034] Connect the circuit with the DC stabilized source turned off, such as figure 1 (a) shown. The upper end of the aluminum wire is connected to the positive pole of the power supply, and the platinum piece is connected to the negative pole of the power supply.

[0035] Turn the longitudinal adjustment knob to raise the holder holding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com