Preparation method of semiconductor nanowire array with optimal photoelectric efficiency

A nanowire array and semiconductor technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, nanotechnology for materials and surface science, etc. It can solve the difficulty of optimizing crystal quality, difficult control of array structure, and harsh measurement conditions and other problems, to achieve the effect of efficient collection, high preparation cost, and large consumption of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In this embodiment, a gallium arsenide nanowire array is prepared by using the preparation method provided by the present invention, and the specific steps are as follows:

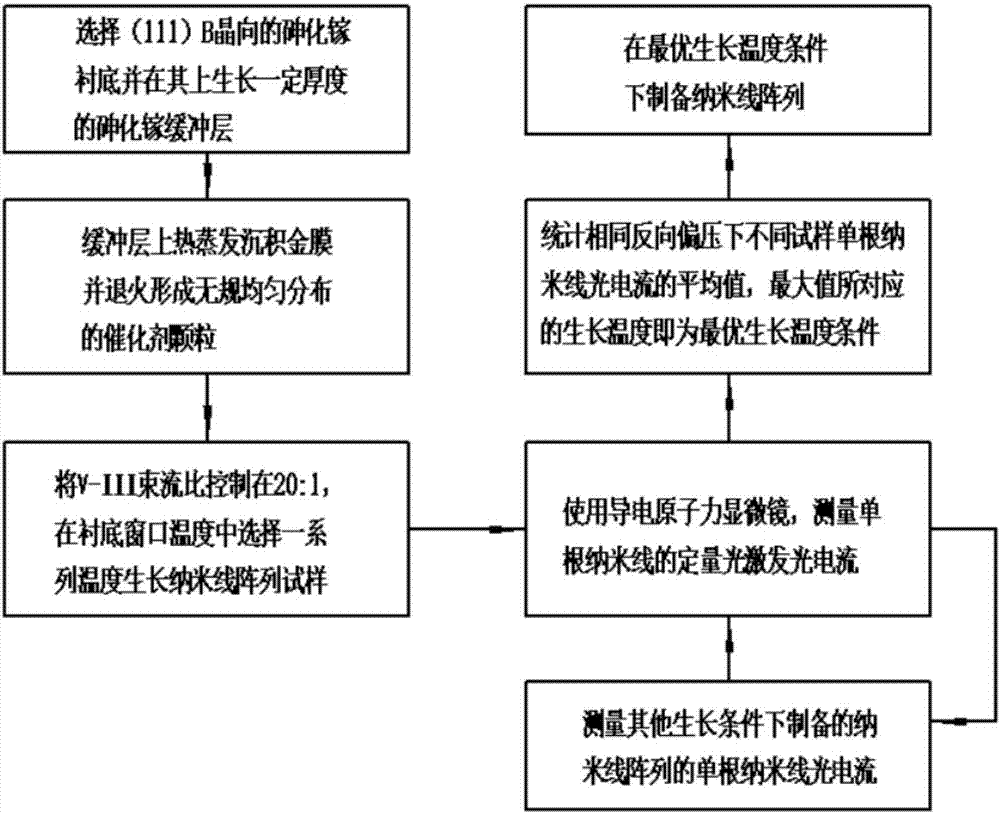

[0021] The preparation process of the semiconductor nanowire array with optimal photoelectric efficiency of the present invention is as follows: figure 1 shown.

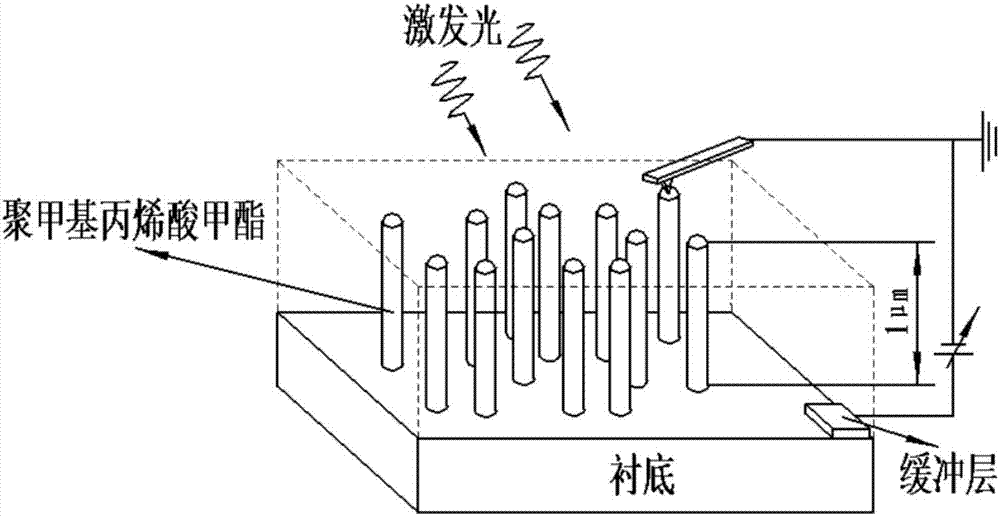

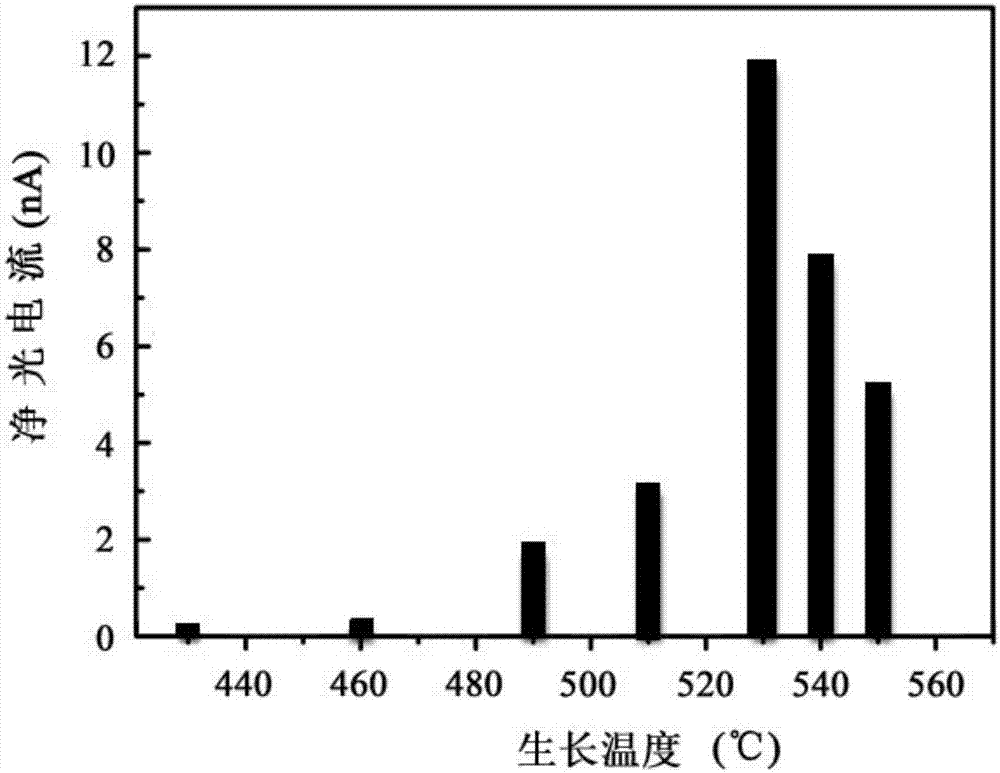

[0022] Firstly, a gallium arsenide substrate with (111) B crystal orientation is selected, the substrate is degassed and deoxidized, and then a 200 nm thick gallium arsenide buffer layer is grown in a molecular beam epitaxy system, and then the gold source is heated by vacuum Heat the furnace to 1000 degrees Celsius, thermally evaporate and deposit a 10-nanometer thick gold film on the buffer layer, and anneal at a substrate temperature of 550 degrees Celsius for 5 minutes to shrink the gold film to form catalyst particles that are randomly and uniformly distributed, and finally use molecular beam epitaxy , the V / III beam ratio is control...

Embodiment 2

[0028]In this example, the preparation method provided by the present invention is used to prepare an indium gallium arsenide nanowire array, wherein the content of the indium component is 30%, and the content of the gallium component is 70%. The preparation of the nanowire array and its photoelectric performance The evaluation process is the same as in Example 1, but the specific parameters are different.

[0029] The substrate window temperature used for growing the nanowire array by molecular beam epitaxy is 406-526 degrees Celsius, and the nanowire array is grown at 406, 436, 466, 486, 506, 516 and 526 degrees Celsius, respectively.

[0030] When using a conductive atomic force microscope to measure the photocurrent-bias curve of a single nanowire in a vertical nanowire array, an excitation light source with a wavelength of 980 nm and a power of 2 mW is used.

[0031] When evaluating the optoelectronic properties of nanowire arrays under different growth conditions, the re...

Embodiment 3

[0033] In this example, an indium arsenide nanowire array is prepared by using the preparation method provided by the present invention. The preparation process of the nanowire array and its photoelectric performance evaluation are the same as those in Example 1, but the specific parameters are different.

[0034] The substrate window temperature used for growing the nanowire array by molecular beam epitaxy is 350-470 degrees Celsius, and the nanowire array is grown at 350, 380, 410, 430, 450, 460 and 470 degrees Celsius, respectively.

[0035] When using a conductive atomic force microscope to measure the photocurrent-bias curve of a single nanowire in a vertical nanowire array, an excitation light source with a wavelength of 2.8 microns and a power of 10 mW is used.

[0036] When evaluating the optoelectronic properties of nanowire arrays under different growth conditions, the reverse bias condition used was 1 volt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com