Ultra-narrow line width and wavelength adjustable composite cavity fiber laser device

A fiber laser and ultra-narrow linewidth technology, applied in the direction of lasers, laser components, phonon exciters, etc., can solve the problems of being easily disturbed by the external environment, difficult to apply on a large scale, and unsatisfactory, and achieving low cost , simple structure and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

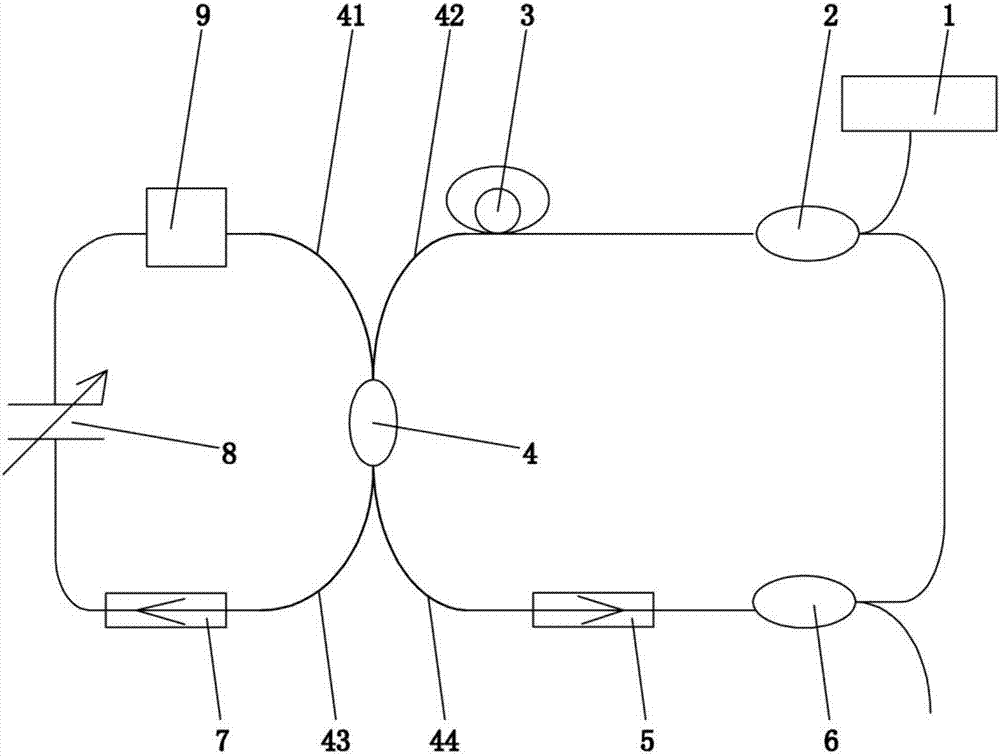

[0024] Such as figure 1 As shown, an ultra-narrow linewidth wavelength-tunable composite cavity fiber laser according to the present invention includes a pump light source 1, a wavelength division multiplexer 2, an erbium-doped fiber amplifier 3, a 2×2 fiber coupler 4, The first optical isolator 5, Y-type fiber coupler 6, tunable F-P filter 8, the second optical isolator 7 and semiconductor saturable absorber 9; the wavelength division multiplexer 2, erbium-doped fiber amplifier 3,2 The ×2 fiber coupler 4, the first optical isolator 5, and the Y-type fiber coupler 6 are sequentially connected to form a ring-shaped main resonator, in which the erbium-doped fiber amplifier 3 and the first optical isolator 5 are respectively coupled to the 2×2 optical fiber The second terminal 42 and the fourth terminal 44 of the device 4 are connected,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com