Reduced graphene oxide with efficient tea matrix adsorption and purification and preparation method and application of reduced graphene oxide

A technology of graphene and tea, which is applied in the field of reduced graphene oxide and its preparation, can solve the problems of efficient adsorption and purification of tea substrates that have not yet been seen, and achieve the effect of cheap price, good purification effect and high purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

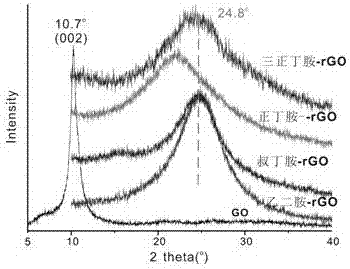

[0027] Graphene oxide material is obtained by taking graphite through the Hummer method; according to the mass ratio of graphene oxide and small molecular amine as 1:0.1, graphene oxide and tri-n-butylamine, tert-butylamine, and ethylenediamine are taken; the graphene oxide material is ultrasonically Disperse in ethylene glycol solvent, ultrasonication for 1 h; add tri-n-butylamine, tert-butylamine, and ethylenediamine into the dispersion, and stir evenly; place in an oven at 180 °C, heat the solvent for 15 h; cool, centrifuge, Wash and dry to obtain the reduced graphene oxide material modified by tri-n-butylamine, tert-butylamine and ethylenediamine. The obtained material was characterized by XRD. from figure 1 It can be seen that the characteristic peak of graphene oxide is 10.7 o Disappeared, after amine modification, at 25 o New broad peaks appear on the left and right, which belong to the characteristic peaks of reduced graphene, and the results indicate that graphene ...

Embodiment 2

[0029] Graphene oxide material is prepared by taking graphite by Hummer method; according to the mass ratio of graphene oxide and small molecular amine as 1:0.5, graphene oxide and n-butylamine are taken; the graphene oxide material is ultrasonically dispersed in ethanol solvent, ultrasonically 1 h; add n-butylamine to the dispersion, stir evenly; place in an oven at 170 °C, solvent heat for 12 h; cool, centrifuge, wash, and dry to obtain n-butylamine-modified reduced graphene oxide material. The obtained material was characterized by XRD. See attached figure 1 .

Embodiment 3

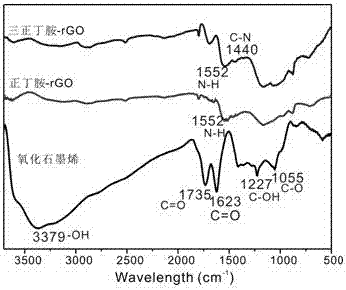

[0031] The tri-n-butylamine-modified reduced graphene oxide obtained in Example 1 and the n-butylamine-modified reduced graphene obtained in Example 2 were further characterized by FTIR. After being modified by tri-n-butylamine and n-butylamine, graphene oxide is at 3379cm -1 The -OH peak weakens obviously, indicating that graphene oxide is reduced during the solvothermal process, and at 1552cm -1 、1440cm -1 The N-H peak and C-N peak appear at , indicating that tri-n-butylamine and n-butylamine have been successfully modified on the surface of reduced graphene oxide. See attached figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com